Threading Tools

Form perfect threads

Threading Tools, for the production of threads have a critical task in common: They are applied at the end of the production chain, when component parts or individual parts are practically finished. Gühring threading tools operate with process reliability – perfect for a demanding machining task at the end of the production chain.

There are several processes to lead to the desired result. No matter if the user decides on fluteless taps, thread taps or thread milling cutters, together with our product management and experienced application technicians we work out the most economical solution for producing a thread.

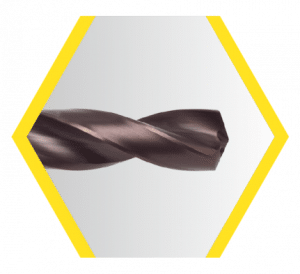

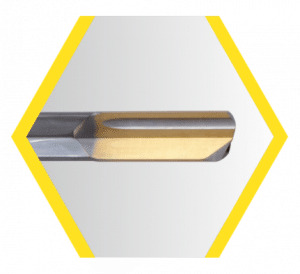

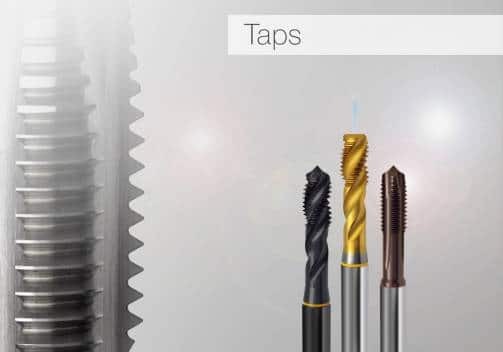

Thread taps

More power for your production – The Gühring Thread taps

Optimized geometries for maximum performance

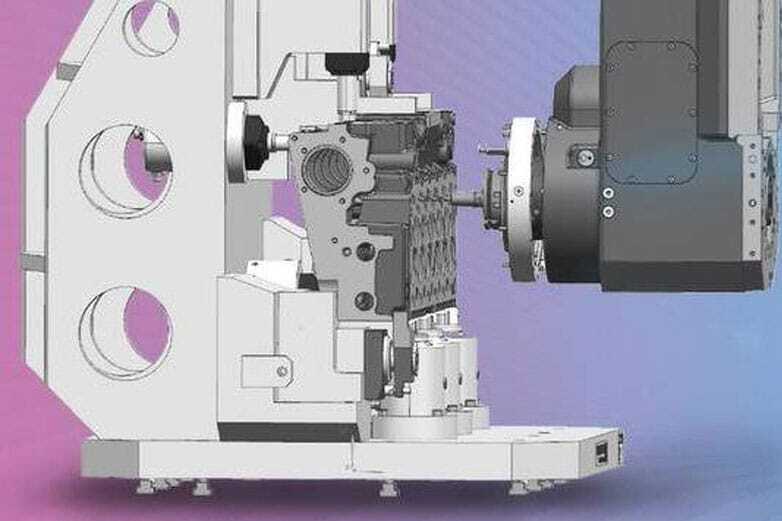

High-precision ground on specially developed machines

Best quality steels as tool material for our thread taps

A complete programme for all standard threads

Estás viendo un contenido de marcador de posición de YouTube. Para acceder al contenido real, haz clic en el siguiente botón. Ten en cuenta que al hacerlo compartirás datos con terceros proveedores.

Más informaciónThread tap Quality “Made in Germany”

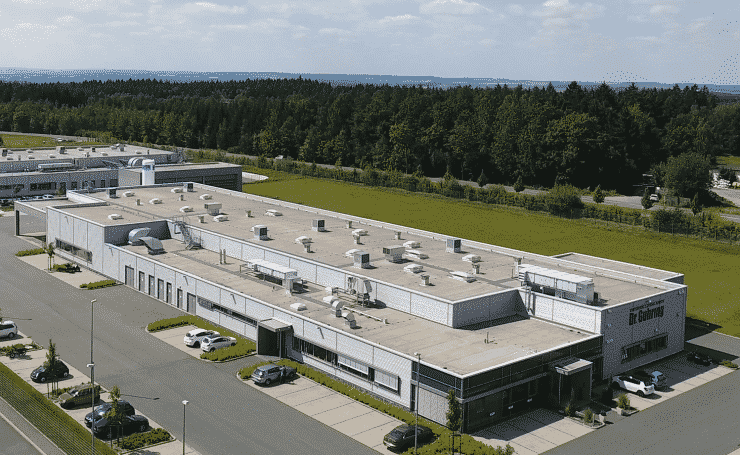

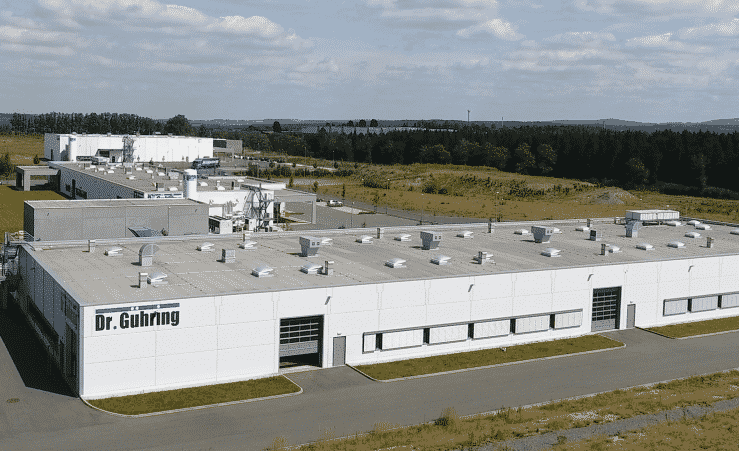

Specially for the PowerTap thread tap line Gühring has invested in new plants in Vogtland on a large scale and since 2011 established a remarkable production location & created in excess of 350 jobs. Designed for international markets available in DIN, JIS and ANSI, PowerTap thread tap follows the philosophy of an unbeatable price-performance-ratio. The threading tools can be applied in most materials & have a golden ring as a distinctive feature. It stands for quality “Made in Germany”.

- 100 % ex-stock availability for our thread taps

- for regional customers with small and medium batch sizes

- Thread taps are applicable in most materials

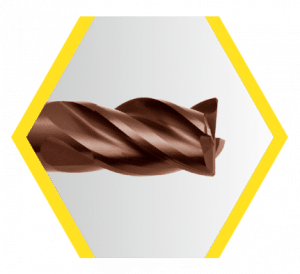

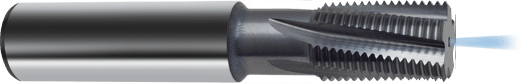

Fluteless Taps

Estás viendo un contenido de marcador de posición de YouTube. Para acceder al contenido real, haz clic en el siguiente botón. Ten en cuenta que al hacerlo compartirás datos con terceros proveedores.

Más informaciónThread mills

NEW NOW: CNC Gühro ThreadMill V4.0

Download CNC Gühro ThreadMill free programming software for thread mills & thread taps:

Download Software CNC Gühro ThreadMill V4.0

215,51 MB

Video: The Guhring thread mill catalogue and CNC-Software explained simply: (German only)

In five steps to the optimal CNC programme

In order to make the machining with Gühring thread mill even more user-friendly, we have developed the intuitive CNC Gühro ThreadMill software.

CNC Gühro ThreadMill is available free of charge. Simply download here!

1. Specifying the thread data

Selection from all current thread standards

2. Selecting the material

You are always assigned the optimal parameters

3. Selecting the tool

Technical data, drawings, machining time and film simplify the selection

4. Recording the CNC data

Input of the desired milling strategy and the parameters

5. Receiving CNC programme with code and data sheet

Programming data (Sinumerik, Heidenhain, Fanuc, Philips, Mazatrol or Hurco) are imported and recognised automatically

Quality from the manufacturer

Our precision for your success

- In-house R&D and mechanical engineering for uniform quality standards

- High process reliability with detailed documentation for our threading tools

- guaranteed repeat accuracy and thread quality

- detailed measurement reports on customer request

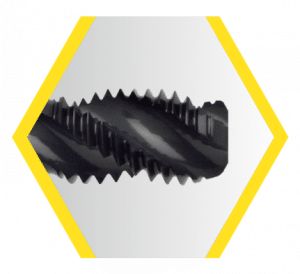

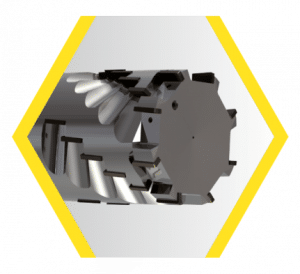

Gühring’s thread mill types

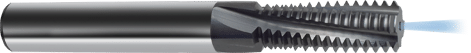

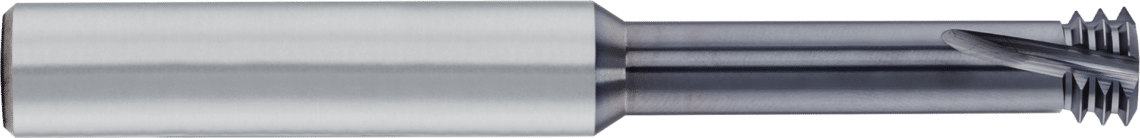

TM SP – thread mill cutter without countersinking step

- Simple and cost-efficient option for milling internal threads

- 2-3 thread sizes with the same pitch can be produced above the specified nominal dimension

- Applications only in materials ≤ 1000 N/mm² available with or without internal cooling

Thread types: M, MF, UNC, UNF, G, NPT

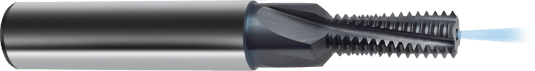

TMC SP thread mill cutters with 45° countersinking step

- Countersinking and thread milling with only one tool

- Very smooth operation and low lateral forces

- Predestined for the application in difficult-to-machine materials even without step

- 2-3 thread sizes with the same pitch can be produced above the specified nominal dimension

- thread mill cutter only available with internal cooling

Thread types: M, MF, G

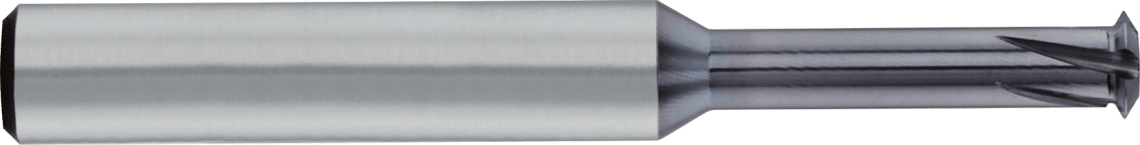

TMU SP universal thread mill cutter with neck recess

- universal application possibilities

- for different thread sizes with the same pitch

- i.e. thread M30x1.5 with milling cutter Ø12xM1.5, Ø16xM1.5 or Ø20xM1.5

- only available with internal cooling

Thread types: M, MF, G, UN, NPT and

External threads M, MF, G

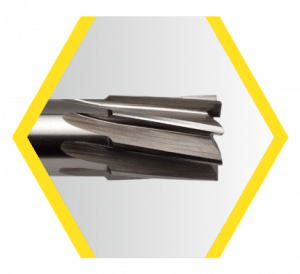

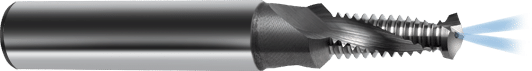

DTMC SP drill / thread mill cutter with 2 cutting edges and 45° chamfer

- Drilling, countersinking and thread milling with only one tool

- Reduced machining times and tool costs as well as reduced space requirement

- Application only in aluminium, cast materials, brass and plastics

- Threading tool available with or without internal cooling

Thread types: M

MTM 3 SP micro thread mill cutter

- Thread size and pitch are predefined

- excellent machining of high-tensile materials such as titanium, VA etc.

- suitable for the machining of hardened steel 45HRC-65HRC

- threads up to 3xD

- Threading tool available with or without internal cooling

Thread types: M, MF, G, UNC, UNF, MJ, UNJC, UNJF

MTM 1 SP micro thread mill cutter

- universal production nominal thread diameters up to a maximum pitch

- Threading tool only available without internal cooling

Thread types: M, MF

OEM - RETOOLING

Strong partner with new processes

AUTOMOTIVE

Complex components, new materials

COMPANY

From drill pioneer to complete supplier