Grooving Tools

Gühring covers all machining operations

With its new grooving tools Gühring is extending its product portfolio with stationary tools for turning operations. In addition to the worldwide most comprehensive programme of rotary cutting tools we have supplemented the subject area with turning and grooving tools. Systems 104 and 106 for boring out, grooving, axial grooving, threading and broaching as well as system 305, a triple exchangeable indexable insert for external and internal machining.

Systems 108 and 110 now complement the range of micro-tools and customer-specific special tools. System 222 is ideally suited for grooving and parting-off applications in steel and stainless steel materials.

Unequalled in-house manufacturing depth

This rapid development in the area of grooving- and turning tools is also made possible by the enormous manufacturing depth of Gühring, which also reaps benefit with a new product group. In-house carbide production for turning tools, specifically developed machines and coatings from the in-house R&D – the way Gühring manages all its products. Now not only with rotary but also with stationary tools.

Downloads / Links

Estás viendo un contenido de marcador de posición de YouTube. Para acceder al contenido real, haz clic en el siguiente botón. Ten en cuenta que al hacerlo compartirás datos con terceros proveedores.

Más informaciónGROOVING TOOL INNOVATIONS

With the comprehensive programme extension with grooving tools Gühring more than satisfies the claim to be a complete supplier: With the new market- and user-friendly additions the programme consists close to 8,000 products.

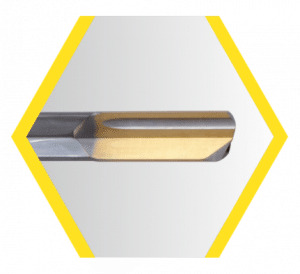

System 222 – for grooving and parting off

System 222 is characterised by high flexibility and process reliability – for grooving and parting-off applications in steel and stainless steel materials.

The cutting insert is available in several designs and features high precision and performance – even with deep grooving and parting off. The chip breaker ensures reliable chip control and optimum chip breakage.

The extensive range of clamping holders and parting-off blades is available with or without internal coolant supply.

Estás viendo un contenido de marcador de posición de YouTube. Para acceder al contenido real, haz clic en el siguiente botón. Ten en cuenta que al hacerlo compartirás datos con terceros proveedores.

Whether long projections or large groove widths and machining depths: System 110 offers optimum solutions for customer-specific special tool needs. The blanks are available with a shank diameter of 10 mm and up to a total length of 112 mm as standard. We would gladly verify the design of even longer tools.

A standard range of different clamping holders completes System 110. For flexibility and stability – even in difficult applications.

System 110

With over 700 different items, System 108 complements the micro-tool range. The wide range of cutting inserts with a shank diameter of 8 mm and clamping holders guarantees maximum stability and a high level of process reliability for turning and profile turning up to tmax. 2.5 mm. The tool solutions of the System 108 are also ideally suited for internal grooving up to tmax 3 mm, reverse turning, axial grooving and for joint machining.

A standard program of the most common clamp holders completes the System 108.

System 104 is added by numerous holder options. Clamping holders in inch sizes are now also part of the standard programme as well as machine specific shanks for Star, Tornos and Citizen machines.

Holders with Polygon and HSK-T shank as well as numerous new options with square shank can be found in the programme extension.

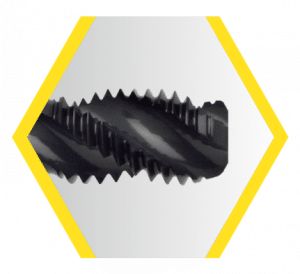

System 106

System 106 is extended to the same extent as system 104 in the clamping holder sector. In addition, a suitable tool can be selected from a significantly more comprehensive portfolio of cutting inserts. New high-lights include:

- Machining diameter from 5 mm

- Cutting inserts for boring and profiling with increased tmax from 1 mm and 2 mm

- Cutting inserts for full profile threading up to M12

Numerous options are available in up to 7 different neck lengths and 5 different corner radii. For machining holes with micro-precision tools, systems 104 and 106 already count as the most comprehensive systems on the market.

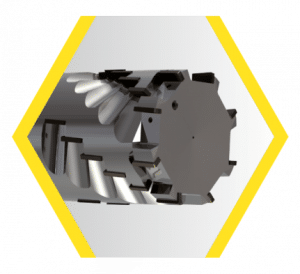

There are also comprehensive product additions to system 305. This includes:

- New clamping holders with small 10×10 mm clamping shank & numerous options in inch dimensions

- Holder for up to 12 mm wide special inserts with wide insert seat as standard product with or without IC

- Inserts with 3 cutting edges for threading

- Cutting inserts with sintered chip breaker

System 305 – for turning tool inserts

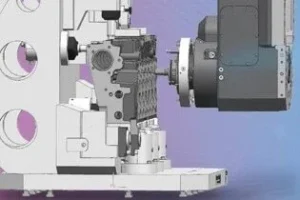

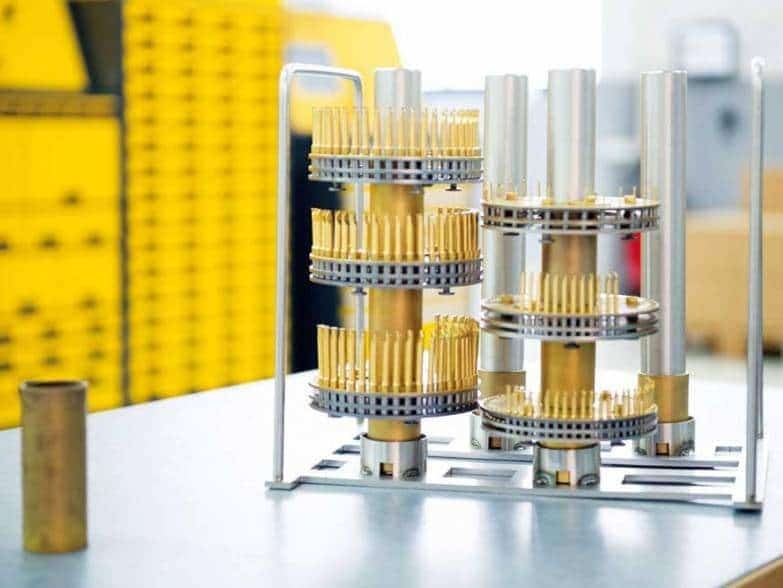

View into our turning tool production

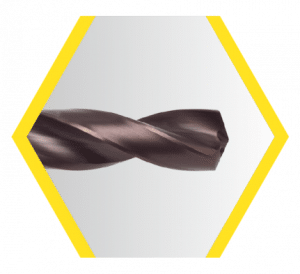

Grinding and grooving tool production

Complete manufacture on in-house designed grinding centres

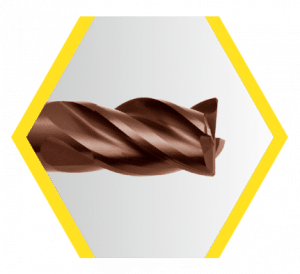

Coating – of grooving tool cutting inserts

In-house coating on in-house designed coating systems for grooving tools

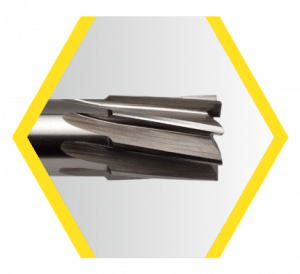

In-house carbide production

Blanks – indexable inserts and cutting inserts, Gühring’s own carbide grades

AUTOMOTIVE

Complex components, new materials

THREADING TOOLS

Form perfect threads

COUNTERSINK TOOLS

Quick, clean & fully automated deburring