RF 100 Diver with internal cooling optimised for drilling and milling

Programme extension for ramping, drilling, slotting, roughing & finishing

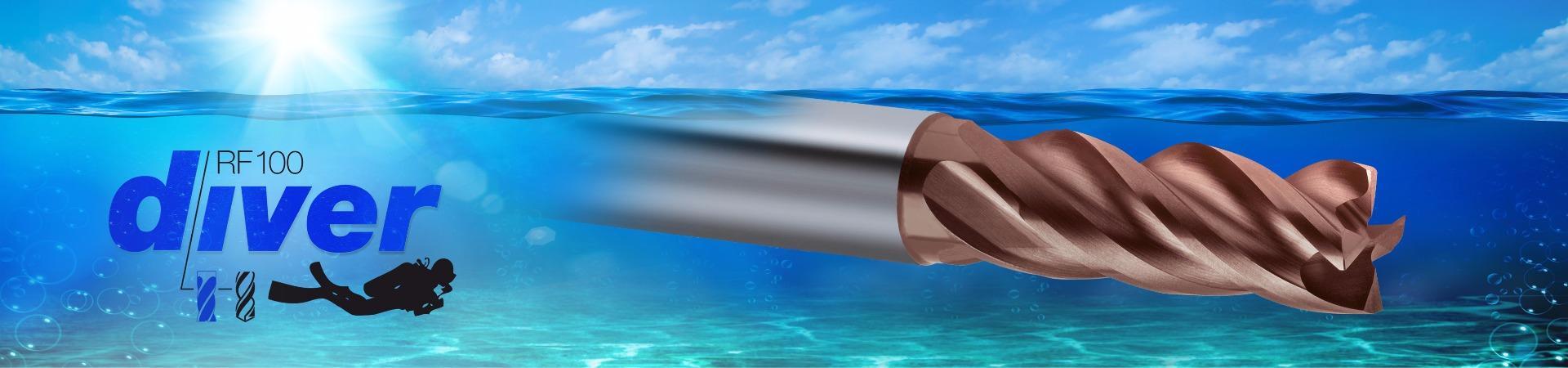

RF 100 Diver has established itself with customers that require high flexibility. The Ratio end mill covers five operations with one tool: It can perform drilling, ramping, slotting, roughing and finishing operations. As well as a programme extension Guhring is now introducing an innovation in the coolant delivery sector: Internal cooling optimised for both milling and drilling.

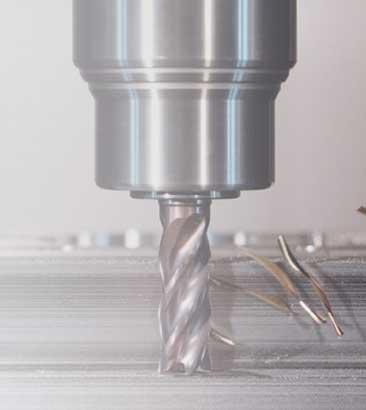

Where drilling tools rely on axial coolant ducts and milling tools on radial coolant ducts, RF 100 Diver offers both, in order to optimally cool and protect the face as well as the circumference geometry when drilling and plunging. Guhring’s decades of know-how in the production of carbide as well as FEM optimisation ensure maximum efficiency in cooling lubrication, chip evacuation and tool stability.

- Up to 40 % longer tool life

- for sticky materials

- for stainless and heat resistant materials

- for process reliable drilling and plunging

- HPC machining

RF 100 Diver

Programme extension for ramping, drilling, slotting, roughing & finishing

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers. More Information

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe new RF 100 Diver is available in the following designs:

3-fluted

- for less powerful machines & clamping conditions

- for turning centres & driven tools

- specially for slotting with smaller milling cutter dimensions

4-fluted short

- for more stability when slotting

- up to 25 % higher feed rate

- reduced deflection

4-fluted

- for stable machines & clamping conditions

- High-performance milling with maximum cutting speeds

DRILLING TOOLS

Sophisticated drill technology

POWERMILL

The complete range of milling cutters

MILLING CUTTERS

Near endless tool life