Optics & Precision Engineering

Extremely small. Ultra-precise.

The miniaturisation of components in numerous industries such as electrical, medical or mechanical engineering requires applications that seemed inconceivable for a long time. The smaller the components the higher the demands on precision, repeatability accuracy and economic efficiency of the process. Particularly in micro-machining the demands are enormous. Demands Gühring can meet with its new product range for micro-machining.

When carrying out milling operations with small tool diameters the deflection of the tool is a significant problem. The high demands of micro-machining call for a prevention or reduction of dimensional deviations caused by tool deflection. For this it is necessary that micro milling tools are especially easy cutting and sharp. High carbide quality, close tolerances and the guarantee of process reliable cooling are absolutely essential already from the blank stage.

In addition, the drilling operation is a central, integral part of micro-technology. Besides standard micro-precision drills, Gühring’s micro-precision drill programme also includes special micro-precision tools in HSS-E-PM and solid carbide on customer request. Due to the increasing miniaturisation, predominantly in telecommunications and in IT, such user-friendly and ex-stock drilling tools are increasingly required. Compared to competing processes such as laser drilling, micro-machining scores points with a more simple integration in the production and economic efficiency.

Also with threading and reaming tools in the micro range a mere miniaturisation of tool manufacture is not sufficient to achieve a satisfactory result. Here it is about making possible series production of electronic components but also components in precision engineering and optics. Therefore, process reliability and tool life counts in order to prevent unnecessary tool change and to ensure an economical production in the micro range.

These factors require manufacturing technologies adapted to the product. Gühring’s special know-how in tool manufacture and grinding quality make it possible to also satisfy these demands for micro machining. Key components here are Gühring’s own carbide as well as the cutting edge geometry and coating.

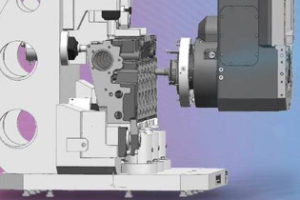

VALUE ADDED-CHAIN

Everything out of one hand

AUTOMOTIVE

Complex components, new materials

COMPANY

From drill pioneer to complete supplier