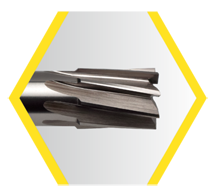

RF 100 Sharp

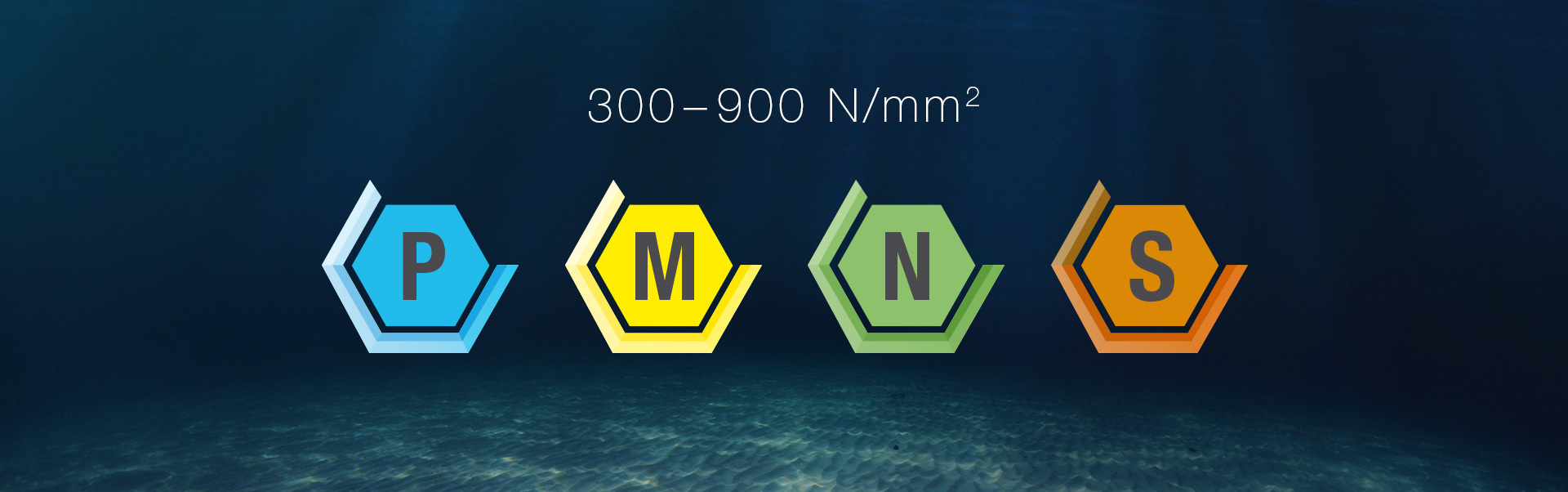

Our sharpest milling cutter especially for effective machining of soft and tough materials under all machine conditions

The machining of soft, tough and highly alloyed materials possess particular challenges for the tool, the wrong choice of tool can result in sticking chips and chip jams. In the worst-case scenario, the tool could break.

You no longer have to worry about this with our new solid carbide RF 100 Sharp milling cutter:

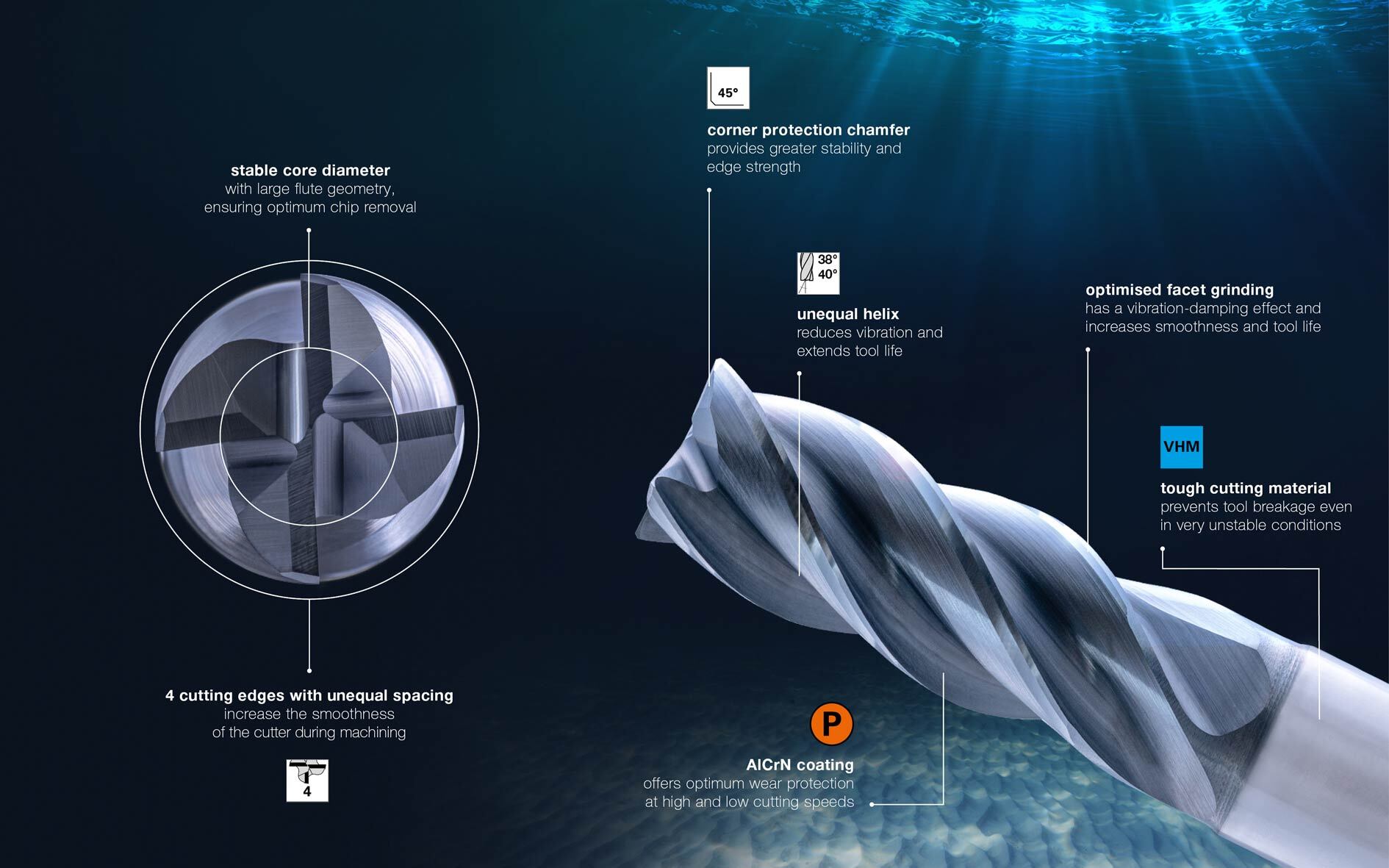

with a rake angle of 12°, it is our sharpest milling cutter and ensures a soft, smooth cut on all soft and tough materials with a tensile strength of 300 – 900 N/mm² and high ductility. The combination of carbide developed in-house and an AlCrN coating enables high-performance machining, not only under stable machining conditions.

The RF 100 Sharp can also handle unstable machines and clamping positions effortlessly.

Thanks to adapted micro and macro geometry, the tool can achieve long tool lives despite the high demands placed on it.

Exceptionally easy cutting on all soft and tough materials thanks to an extremely sharp rake angle

A rake angle of 12° enables reduced cutting pressure and cutting forces, which means the RF 100 Sharp can easily cut through all soft, tough and highly alloyed materials with a tensile strength of 300 – 900 N/mm² and high ductility. For example, free-cutting and case hardened steels, stainless steels as well as tough special alloys and high-strength aluminium alloys.

Below is a selection of common materials that can be optimally machined with the RF 100 Sharp:

| ISO code | Material no. | Old abbreviated name | New abbreviated name |

| P / steel | 1.0715 | 9 SMn 28 | 11SMn30 |

| P / steel | 1.0401 | C 15 | — |

| P / steel | 1.0503 | C 45 | C45 |

| P / steel | 1.0039 | St 37 -2 | S235JRH |

| P / steel | 1.0419 | St 52.0 | L355 |

| P / steel | 1.7131 | 16 MnCr 5 | 16MnCr5 |

| M / stainless steel | 1.4021 | X20Cr 13 | X20Cr13 |

| M / stainless steel | 1.4301 | X5CrNi 18 10 | X5CrNi18-10 |

| M / stainless steel | 1.4305 | X10CrNiS 18 9 | X8CrNiS18-9 |

| M / stainless steel | 1.4541 | X6CrNiTi18 10 | X6CrNiTi18-10 |

Specialist in soft and tough materials, generalist in applications:

The RF 100 Sharp can be used for slotting, roughing, finishing, ramping and helical plunging processes. This makes our sharpest milling cutter your universal tool for machining soft and tough materials with high ductility. The smallest diameter starts at 1 mm, meaning the Sharp is perfect for use in the micro range. It is an ideal complement to our RF 100 Microdiver: as a 4-flute cutter, you can use our new milling cutter for finishing after roughing with the micro diver to significantly improve the surface finish.

Powerful and smooth under all operating conditions

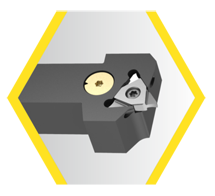

Whether it’s a powerful CNC milling machine or a power-limited lathe: the RF 100 Sharp solid carbide milling cutter is designed to cover all of the different operating conditions, it always achieves excellent results:

under stable machine conditions, it enables HPC milling with extremely high cutting speeds and high metal removal rates. In addition to conventional machining, the milling cutter is also suitable for GTC machining (Gühring Trochoidal Cutting). However, even unstable machines or clamping setups (MTC) are no trouble for the sharp solid carbide cutter, it handles these conditions with ease while ensuring low-vibration operation and the best results. The carbide used is characterised by its relatively high toughness, which prevents the cutter from breaking under suboptimal conditions or slow cutting speeds. The AlCrN coating offers high wear protection with aggressive cutting parameters. The chromium provides additional oxidation protection, making the coating and milling cutter ideal for slower cutting speeds.

See the performance of the RF 100 Sharp under different operating conditions for yourself:

Effective, smooth cutting even with less powerful machines and unstable clamping setups

Application data for the video

| Machine | Spinner TC 600 CNC lathe | |

| Milling tool | RF 100 Sharp, part no. 6478, Ø 10 mm, Z=4 | |

| Operating condition | MTC | |

| Milling operation | Hexagonal milling | |

| Tool holder | BMT LIFE TOOL ER 25 collet chuck | |

| Material / component | 1.7131 or 16MnCr5 / shaft | |

| Cutting parameters | vc | 130 m/min |

| S | 4,138 rpm | |

| fz | 0.07 mm | |

| Vf | 1,158 mm/min | |

| ae | 8 mm | |

| ap | 3.8 mm | |

| Metal removal rate Q | 35 cm³/min | |

| Tool life | 78 min | |

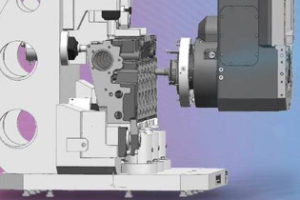

High-performance milling with extremely high cutting speeds under stable operating conditions

Application data for the video

| Machine | CNC MACHINING CENTRE DMG DMU 100 P | |

| Milling tool | RF 100 Sharp, Ø 16 mm, part no. 6479 | |

| Operating condition | HPC | |

| Milling operation | Contour roughing | |

| Tool holder | HSK 100 A GühroJet Weldon tool holder | |

| Material / component | 1.0503 or C45 / block | |

| Cutting parameters | vc | 180 m/min |

| S | 3,580 rpm | |

| fz | 0.1 mm | |

| Vf | 1,430 mm/min | |

| ae | 6 mm | |

| ap | 34 mm | |

| Metal removal rate Q | 291 cm³/min | |

| Tool life | 134 min | |

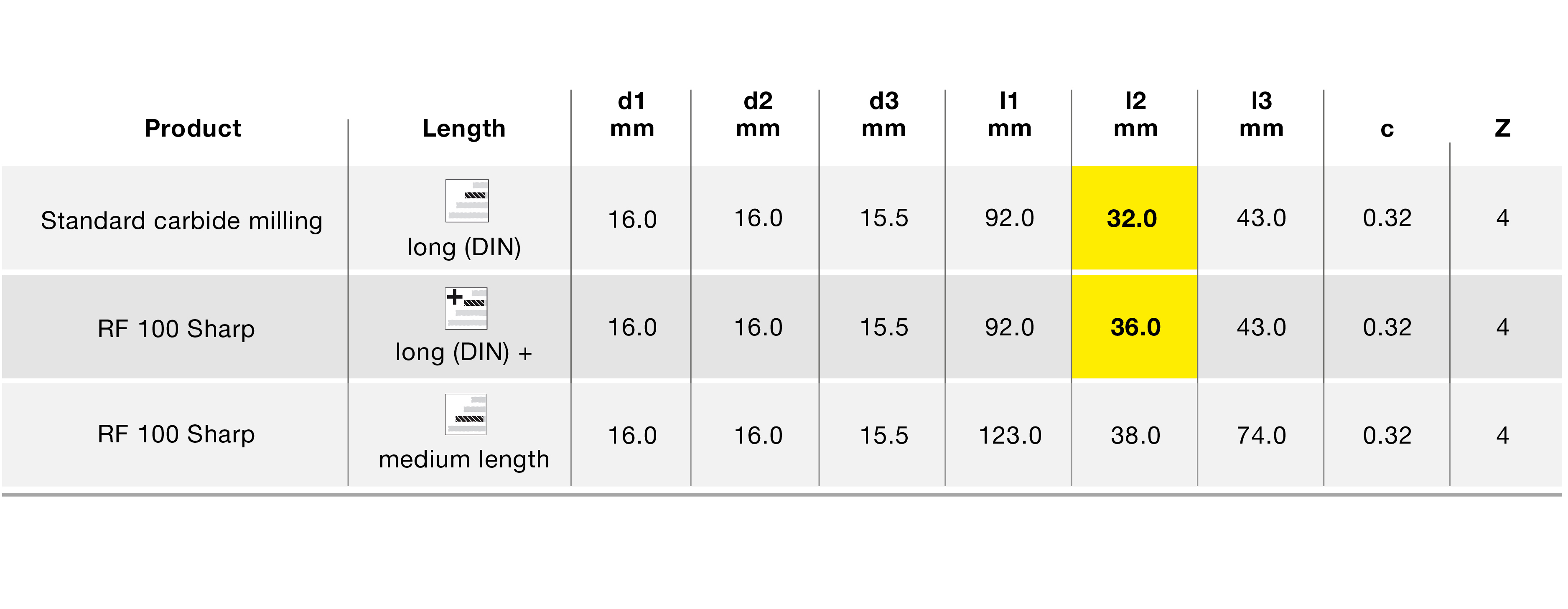

Application-oriented dimensions

for cost-effective machining

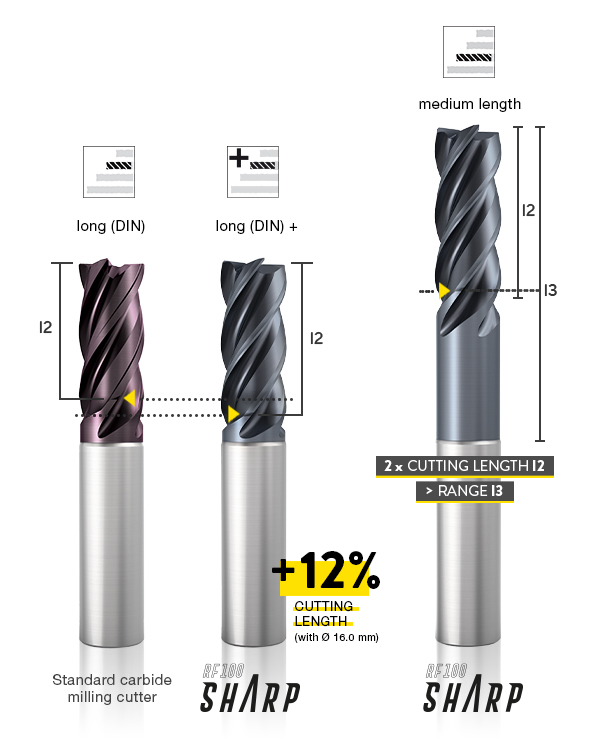

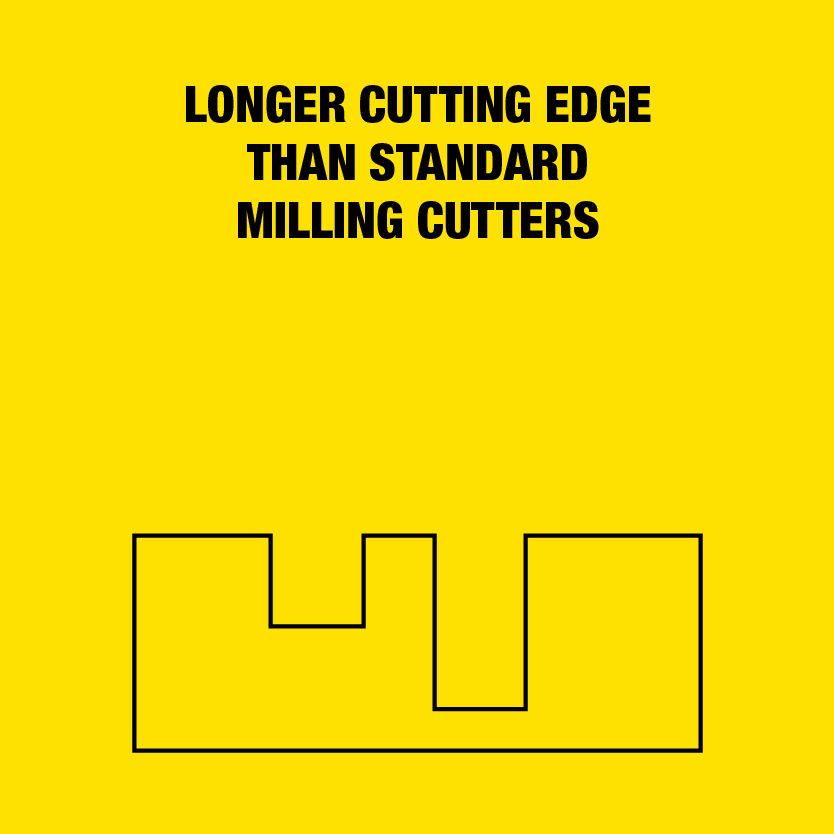

With RF 100 Sharp, we have added an extra long milling cutter to our portfolio for the first time. This variant is based on “long (DIN)”, but has a longer cutting edge than the standard milling cutter – you benefit from this in three ways:

- Reduce your tooling costs: when machining longer depths, you can now use a cheaper milling cutter with a smaller diameter.

- Save space in the tool magazine: thanks to the flexible use at different depths, you need a smaller selection of milling cutters.

- Extend the tool life: due to the extra length, you can regrind and recoat the milling cutter more often.

For even greater depths, the RF 100 Sharp is also available in a medium-length version. This version is designed so that the cutting edge (l2) represents more than 50% of the reach (cutting edge + neck) (l3).

This allows the customer to machine their workpiece (l3) with only two milling paths.

The following example illustrates the differences in length:

AT A GLANCE – the RF 100 Sharp is the BEST choice:

RF 100 Diver

for maximum flexibility in all milling operations

RF 100 Speed

for effective HPC machining in steel and stainless steels