Gun Drills

For every task a suitable gun drill

For a diameter-length-ratio from 15xD one generally refers to gun drilling. Gun drills are for example applied for the machining of camshafts, crankshafts, drive shafts, injectors, drill pipes for oil production, in the medical and the food industry. Dependent on the requirements of the hole, the machine conditions, the batch size and the drilling depth Gühring determines the most economically efficient tool option.

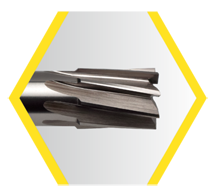

Single-fluted gun drill

EB 100 M: THE ROBUST

\ single-fluted gun drill especially for close drilling tolerances

\ can be manufactured from 1,000 mm up to 16,000 mm nom.-Ø

\ flute length up to 580 mm

\ up to 80xD with only one tool

\ suitable for MQL applications

\ suitable deep drilling for most materials

\ wide variety even of inch dimensions

EB 80: CONVENTIONAL

\Total length to 3.600 mm

\ nominal diameter from 2,000 mm to 40,000 mm

\ wide range of options, i.e. ball nosed or step drill

\ suitable for most materials

\ wide range for machining centres and deep drilling machines

\ wide variety of deep drilling even of inch dimensions

\ fast service programme EB 80

ZB 80: THE SPECIALIST FOR CAST IRON

\ total length to 1.000 mm

\ nominal diameter from 6,000 mm to 30,000 mm

\ perfect for machining of cast iron

\ specifically developed carbide grades and cutting edge geometries for innovative deep drilling

TBV 116: FOR Ø 3 UP TO 32 MM

\ standard and special grinding operations

\ no minimum flute length

\ support device available for long tools

\ universal application on any type of grinding machines

EB 100: THE SMALLEST

\ single-fluted gun drills especially for close dilling tolerances

\ can be manufactured from 0,900 mm up to 16,000 mm nom.-Ø

\ flute length to 580 mm

\ up to 80xD with only one tool

\ suitable for most materials

\ wide variety of deep drilling even of inch dimensions

\ fast service programme EB 100

EB 800: THE FLEXIBLE

\ total length to 3.600 mm

\ nominal diameter from 12,000 to 52,000 mm

\ convertible by 0.5 mm per basic body range

\ any combination of carbide grades and coatings possible

\ suitable for most materials

TBM 116: UNIVERSAL MANUAL GRINDING MACHINE

\ ideal for regrinding for small and medium quantities of tools with

different diameters and lengths

\ easy mounting of lateral chip breakers on single-fluted gun drill

TBV 216: FOR Ø 0,5 UP TO 6 MM

\ max. length 350 mm

\ easy handling, requiring just four working steps

\ grinding with a 3-axis swivel

\ various grinding angles are possible

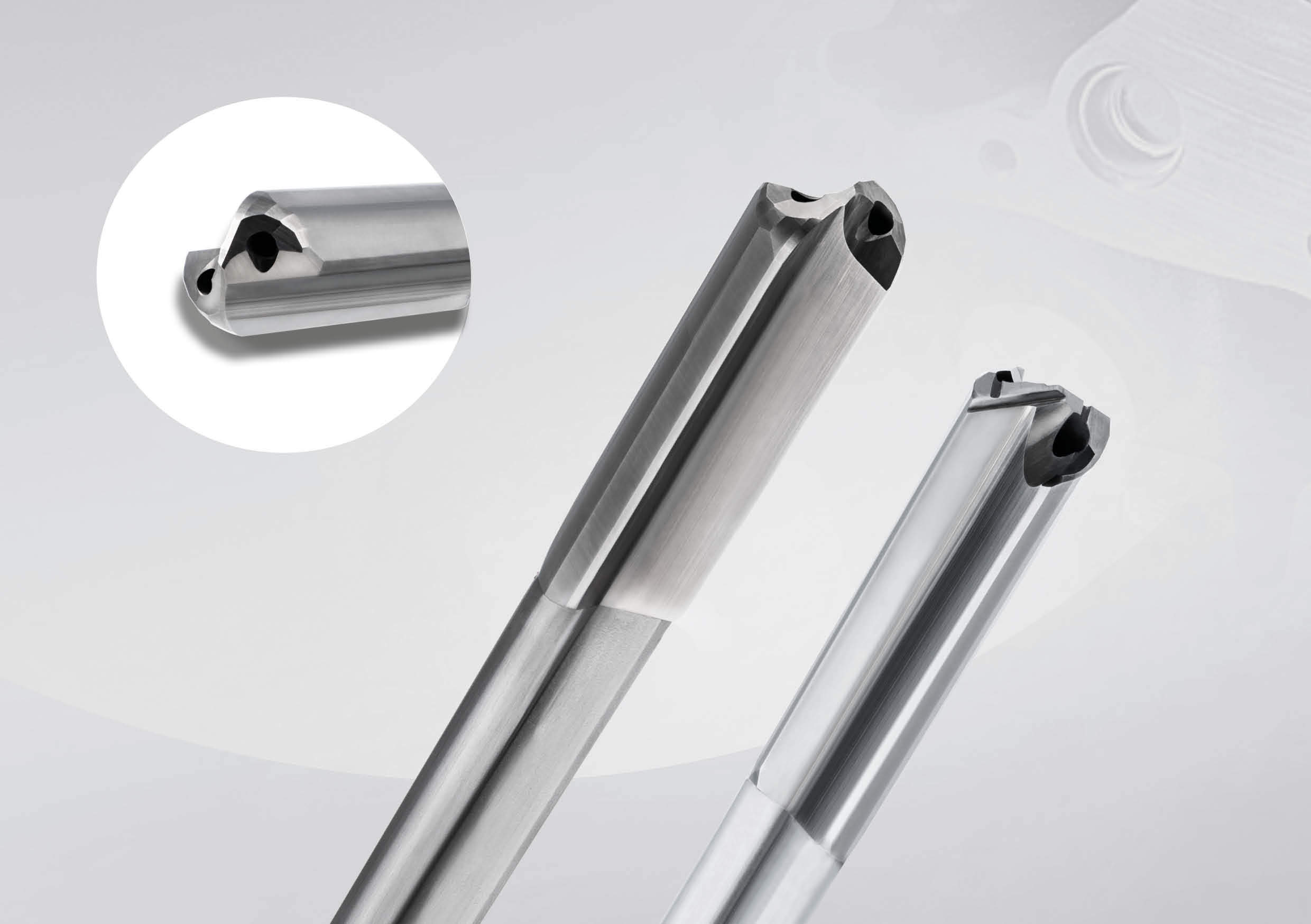

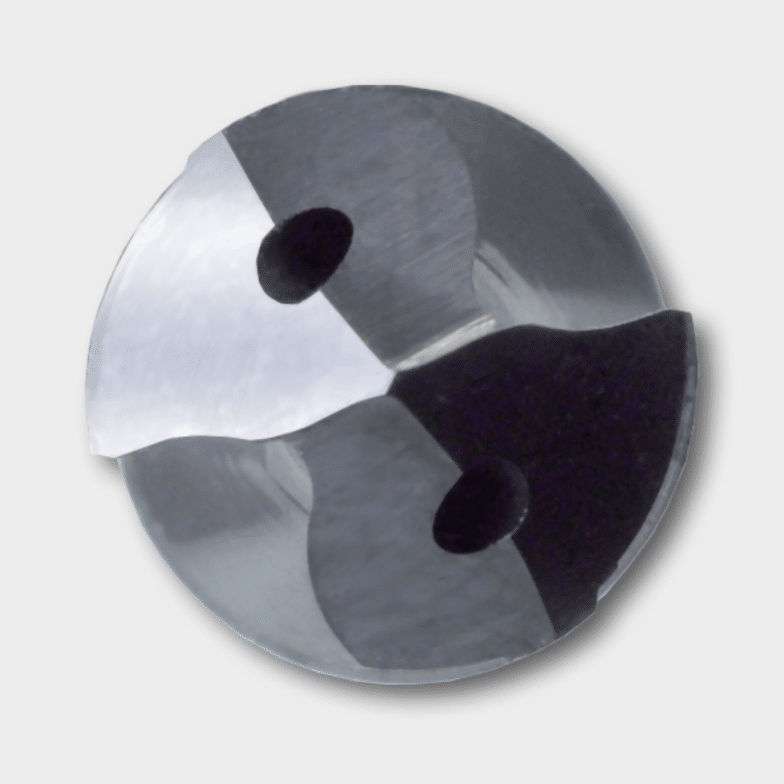

Deep hole drilling with solid carbide spiral fluted gun drill

EXCLUSIVE LINE: RT 100 T

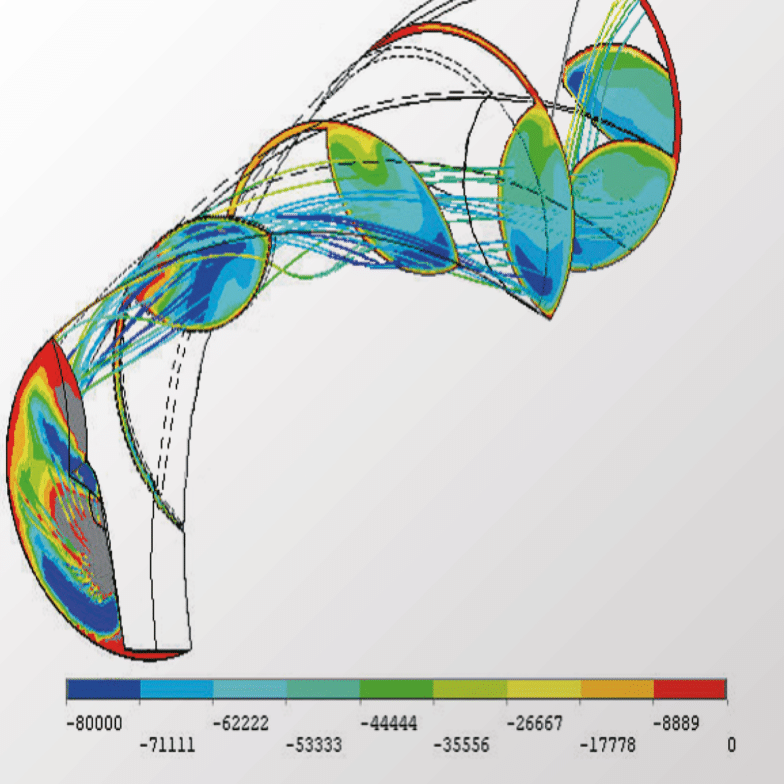

With spiral deep hole drills type RT 100 T available as part of an extended ex-stock programme for the drilling depths 15xD, 20xD, 25xD, 30xD and 40xD, the user benefits from maximum feed rates and cutting speeds and therefore benefits from a significant reduction in manufacturing times. Gühring achieves these advantages thanks to the following features:

- Optimised flute cross-section gun drilling

The spiral deep hole drills have a groove geometry specially adapted to the special requirements for optimum chip transport from deep holes. - Maximum coolant duct cross-section

To optimally supply the cutting edge with lubricant, the tools possess coolant ducts with maximum cross-section. This ensures an effective lubricant supply to the cutting edge and excellent chip evacuation. - Problem-free chips

The aforementioned factors in combination with the perfectly adapted cutting parameters to suit the application result in chips that are evacuated problem-free even from deep holes. Therefore, chip congestion and the herewith combined jamming of the tool is effectively prevented.

- Wear resistant cutting edges

Thanks to the head coating with Gühring’s A-coating (TiAlN) the heavily stressed cutting edge area is effectively protected against wear. - HA shank for accurate clamping

For clamping with hydraulic chucks from Gühring’s GM 300 programme the RT 100 T ex-stock range is equipped with a HA shank, shank tolerance h6. The combination of RT 100 T and hydraulic chuck guarantees maximum concentricity, extreme clamping force, minimal imbalance and optimal economic efficiency. - Intermediate dimensions & special lengths

In addition to the ex-stock programme ensures Gühring continues to provide RT 100 T as a special tool to customer requirements. We provide intermediate dimensions for the ex-stock range with a maximum drilling depth up to 40 x D / a maximum total length up to 400 mm. - MQL suitable

Thanks to the modification of the shank to the for MQL machining optimised shank end the ex-stock tools are also optimally suited for MQL machining.

HSS-E-PM deep hole drill: GT 2000

Drilling depths up to 20xD without pecking cycles

- Special deep drilling programme

- Ø 3.00 -12.00 mm

- up to 20xD drilling depth

- new parabolic flute geometry for optimal chip evacuation

- especially suitable for the machining of steel

- The TiAlN-based head coating ensures a high wear resistance of the stressed cutting edge of the tool during heavy machining.

Point grind

Optimal wear resistance and excellent cutting conditions with deep holes thanks to the newly developed point geometry with optimised S web thinning.

Flute form

A specially developed parabolic flute form with optimised surface finish quality ensures optimal chip formation and chip evacuation.

High surface finish quality

Thanks to the bright flute with high surface finish quality the chips are optimally evacuated.

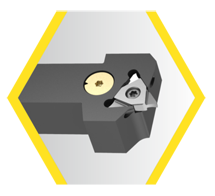

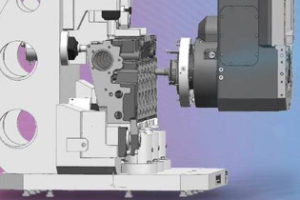

CLAMPING SYSTEM

Precision is setting-up matter

DRILLING TOOLS

Sophisticated drill technology

AVIATION

Highest requirement for tool & process