Modular drilling systems with bayonet interfaces enable quick drill head changes directly in the machine – but with insufficient process reliability and short tool lives, this time saving can quickly become relative. The BT 800 from Gühring shows that easy handling and strong performance are not mutually exclusive – and shines with 150% longer tool life compared to the competition.

Tradition, innovation and reliability – these are the values that Salzgitter Mannesmann Stahlhandel GmbH stands for as a producer and distributor of high-quality steel products. These include flat products, tubes and long products, which are not only characterised by a wide and flexible standard product range of dimensions and grades, but also meet the highest quality standards.

In order to meet the growing demands for efficiency and precision, the company, headquartered in Mühlheim an der Ruhr, focuses specifically on modern tooling solutions. These include modular drilling systems, from which Salzgitter Mannesmann expects more cost-effective and time-saving drilling processes, especially for larger diameters.

Quick change thanks to the bayonet interface

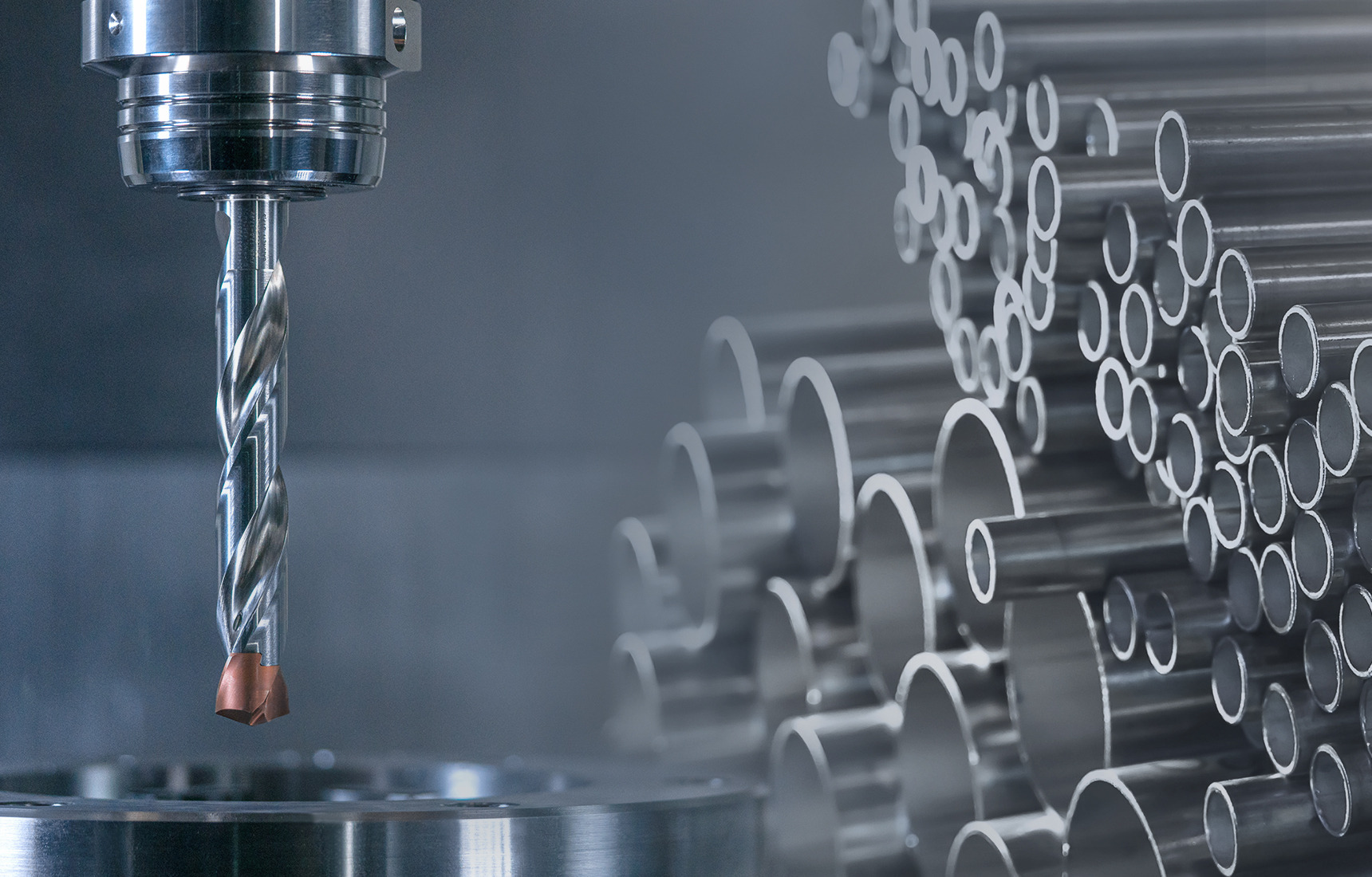

Production employee Tino Becker explains why interchangeable head systems with bayonet locks are particularly effective: “The drill head can be replaced easily and directly in the machine. Compared to alternative modular drilling systems, where the drill head is secured with a screw, we save a lot of time because the drill does not have to be removed from the machine and the programme interrupted.”

Tool breakouts & unclean holes

That is why Salzgitter Mannesmann initially opted for a drilling system from a competitor of Gühring with a bayonet interface. However, it soon became apparent that simply changing the drill head quickly and easily was not enough when problems arose during an application in mild steel: the company had to struggle with long chips and loud drilling noises. This resulted in unclean holes and even tool breakage: “If the holder is also damaged in the process, it can quickly become expensive. The cost-effectiveness of modular tools is then lost”, summarises Tino Becker.

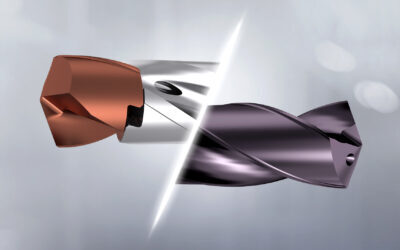

150 % longer tool life with the BT 800

“We can do better than that”, says Gühring application technician Tobias Förderer, proposing a new solution to the long-standing customer: Gühring’s BT 800 interchangeable head drilling system combines the advantages of a handy bayonet interface with the performance of solid carbide drills and a long life. Salzgitter Mannesmann is convinced of this in the manufacturing of steel beams (mild steel S355 J2), where through-holes with a diameter of 17.5 mm are to be produced on a Kaltenbach drilling saw system.

And the BT 800 delivers what it promises: “Not only is it easy to handle during replacement, we are also very satisfied with its process reliability and hole quality”, confirms Tino Becker. “Compared to the competition, we were able to increase the tool life from 1,333 holes to 3,320 holes.” And that’s not all: the carbide head of the BT 800 can be reground up to two times. This allows the customer to further reduce the cost of procurement of more expensive new tools.

“The interchangeable head drilling system from Gühring is the most cost-effective alternative – the BT 800 has convinced us.”

Tobias Förderer explains how the BT 800 achieves this: “In combination with the wear-resistant Persistum coating, the carbide drill head boasts a long life and maximum resistance to thermal influences. The polished flutes in the holder ensure high process reliability by guaranteeing perfect chip removal. The coolant ducts with maximum cross-section and exits in the flute ensure optimum cooling lubrication.” Salzgitter Mannesmann also does not have to worry about chip jamming: the combination of geometry, polished flutes and cooling ensures optimum chip breaking and removal from the hole. “The Gühring interchangeable head drilling system is the most cost-effective alternative – the BT 800 has convinced us”, summarises Tino Becker.

Tool tip: BT 800 – the better choice

Modular interchangeable head drilling system

BT 800

for quick head changes and high cost-effectiveness

The BT 800 allows different drill heads to be used on a standard steel cutting body. This enables you to quickly adapt the tools to different materials or machining requirements.

Your advantages with the BT 800:

- quick and easy handling combined with long life and high performance

- cost-effective alternative to solid carbide drilling

- minimisation of set-up times

You may also be interested in:

Carbon masks save sports stars: customised high-tech orthoses with precision from Gühring

Especially for a team’s top performers, an injury due to a broken nose or cheekbone is catastrophic. This is precisely when Malzkorn’s product comes into play: carbon fiber-reinforced face masks for elite athletes.

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.