30.05.2025

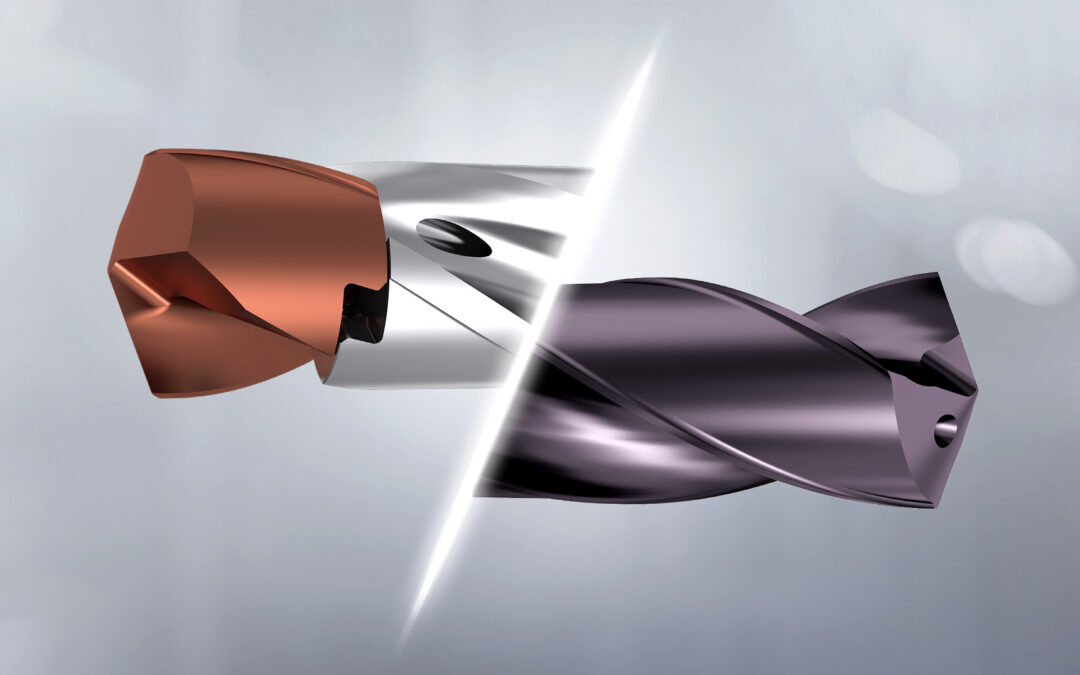

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.

09.04.2025

An innovation – the new modular fluteless tap from Gühring – has made it possible to solve deep-seated challenges in the production of blind hole threads at Karl Georg and to raise process reliability to a new level.

09.04.2025

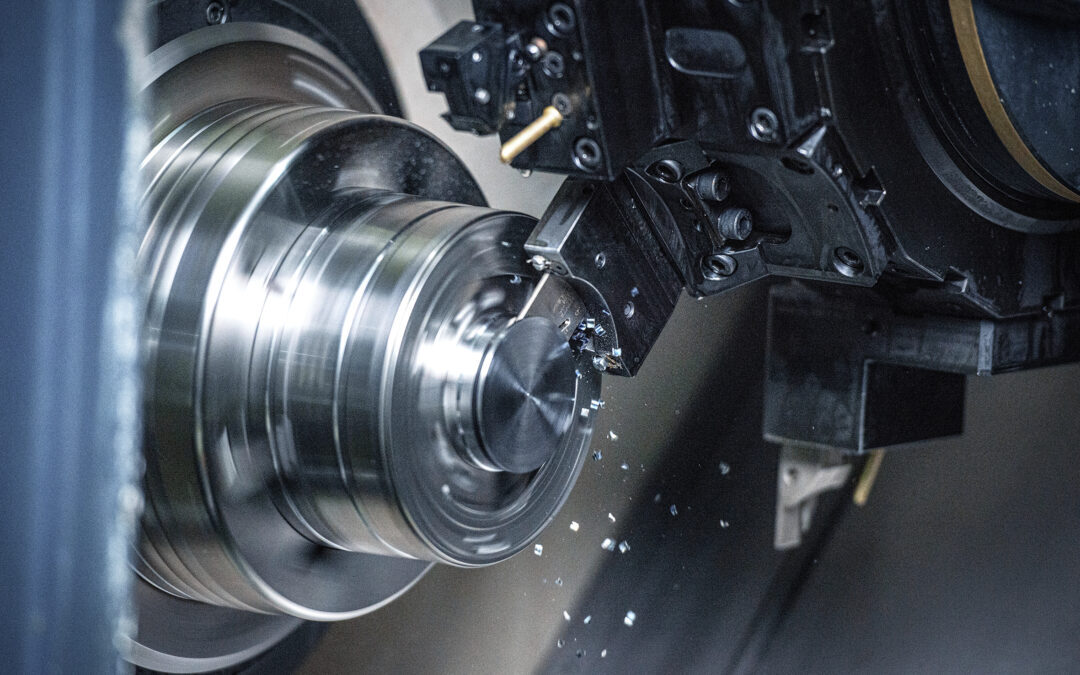

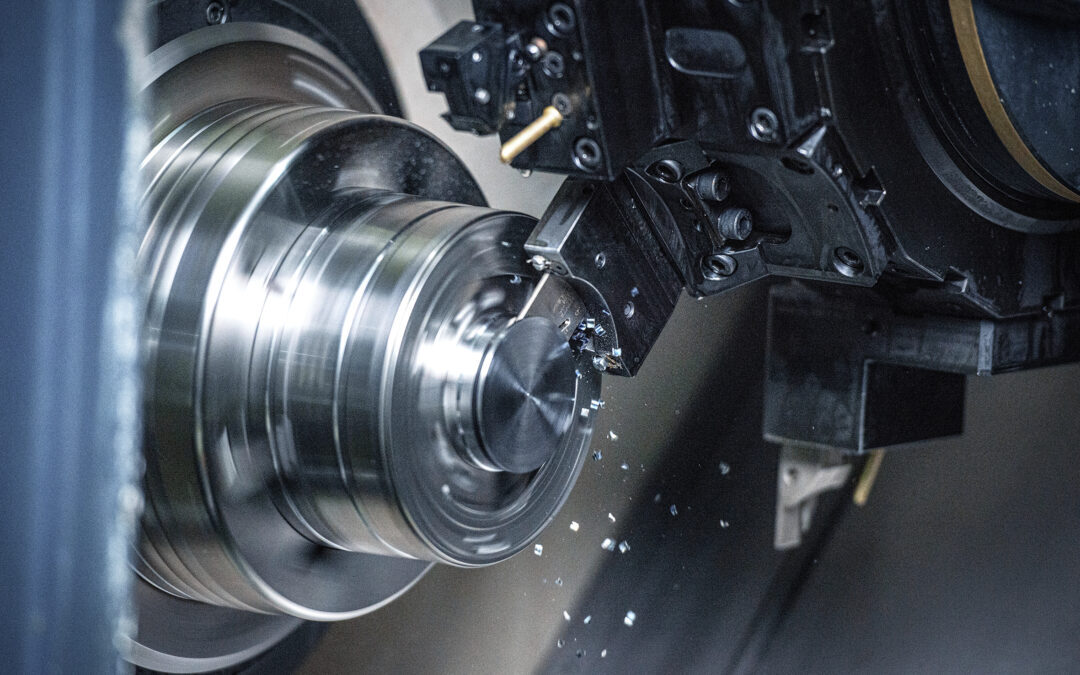

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

09.04.2025

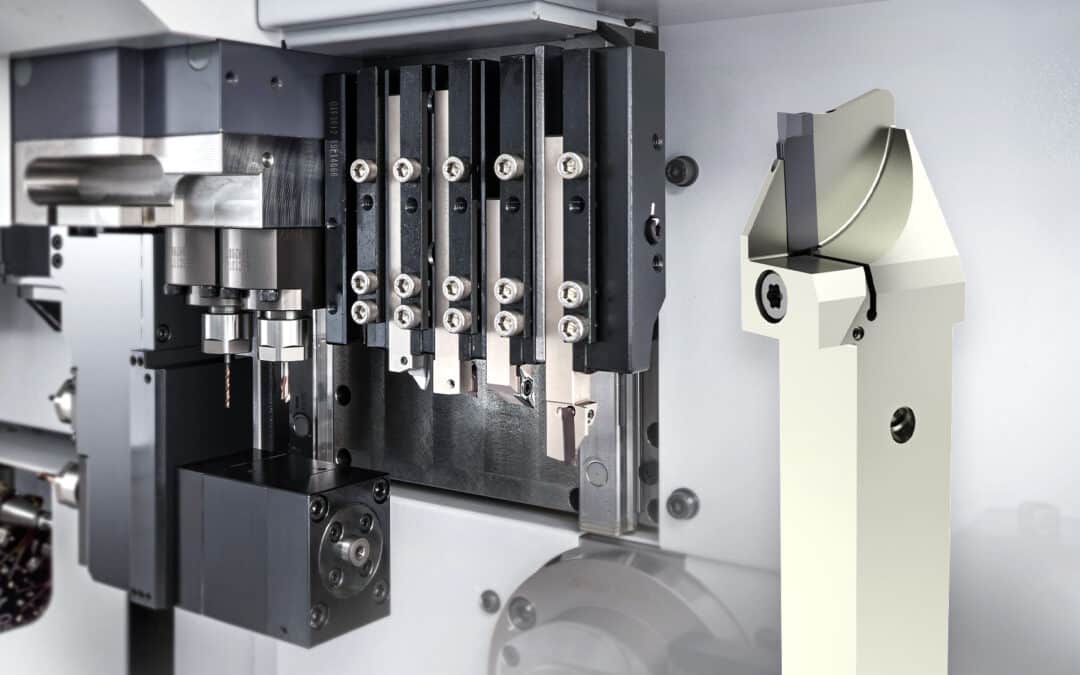

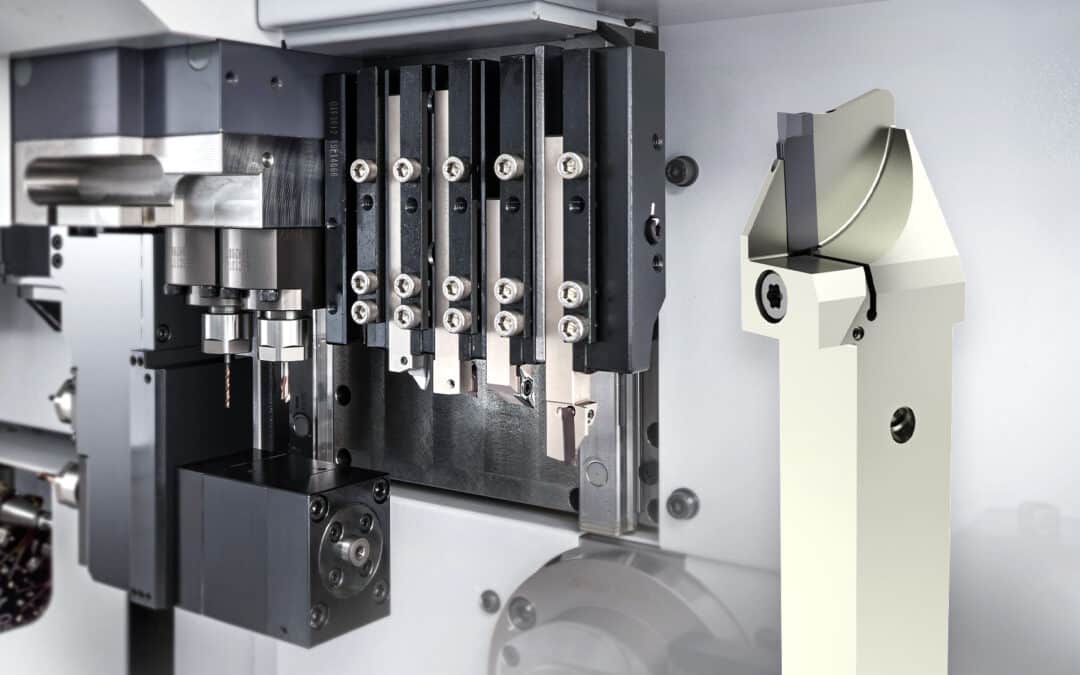

Discover our tool holders for sliding headstock lathes from system 222 with shortened head length, precision cooling and easy insert change – ideal for tight spaces and maximum process reliability when grooving.

22.08.2024

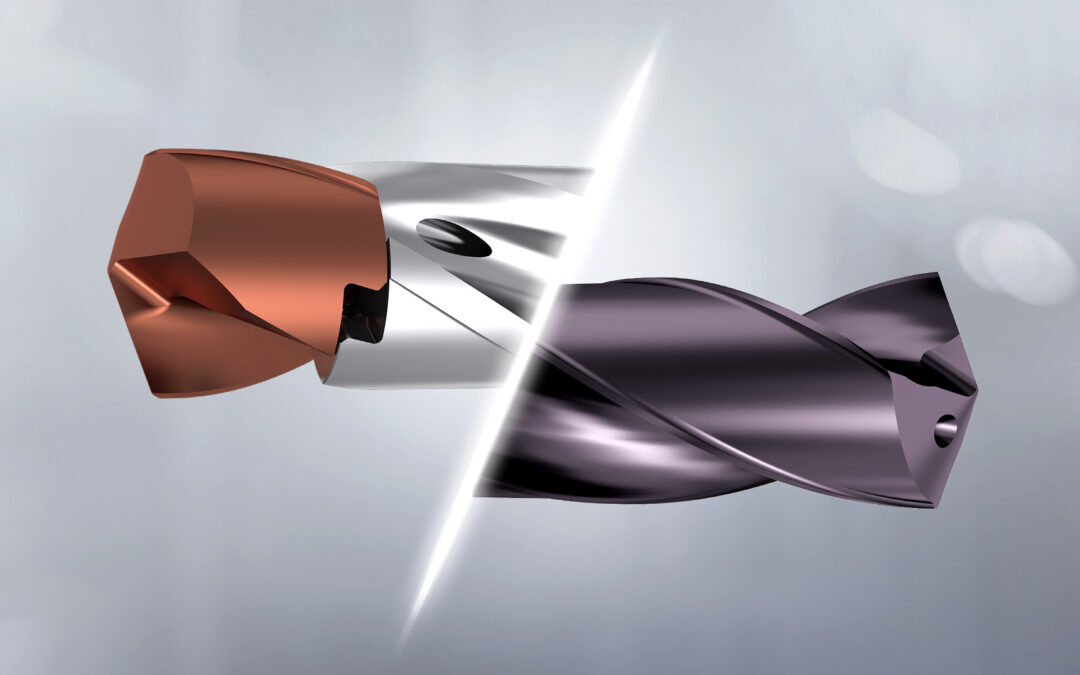

With the new high-performance tools for stainless steel machining, Gühring offers the optimal solution. Special coatings and adapted geometries guarantee the highest cutting values and extended service life. This means that the most demanding machining tasks can be mastered in a wide range of industries.

22.08.2024

The RF 100 AL Micro offers an outstanding combination of precision, efficiency and process reliability, making it the first choice when machining aluminium, copper and brass. With its innovative properties this tool raises the bar for micro-machining.