Welcome to Gühring

What do you want to do today?

Our service for you

Gühring: Tool manufacturer with service guarantee

Your success is our mission

Gühring is one of the world’s leading manufacturers of rotating tools for metal processing. We produce over 5,000 different types of tools and more than 100,000 different items. Every year, more than 500 original equipment projects are undertaken according to the individual requirements of our customers.

As a tool manufacturer, we combine all the necessary expertise under one roof: From in-house mechanical engineering to the production of our own carbide to the development of new coatings. Within a century, Gühring has developed from a twist drill manufacturer to a full-service provider in the field of machining.

What sets us apart from other providers

Products

Subsidiaries worldwide

Sales representatives

around the globe

Tonnes of carbide/year

News

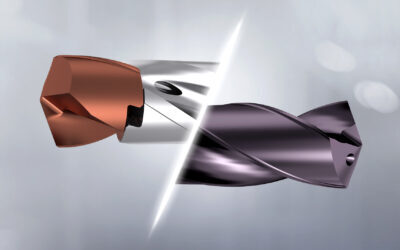

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.

Threads for giants: Crane manufacturer relies on modular fluteless tap for blind holes

An innovation – the new modular fluteless tap from Gühring – has made it possible to solve deep-seated challenges in the production of blind hole threads at Karl Georg and to raise process reliability to a new level.

30% more tool life: With this parting off plate you achieve maximum performance in high-grade steel

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

Cutting

Precision machining – that’s what Gühring stands for. With our tools, we are one of the world’s leading manufacturers in the field of metal machining.

What is cutting?

Cutting tools have one or more wedge-shaped cutting edges. These penetrate the material through force and produce swarf. The more force exerted on the cutting edge, the deeper it penetrates.

What are clearance angles, wedge angles and cutting angles?

The angles between the workpiece and the cutting edge influence the machining process and vary depending on the material to be machined.

The clearance angle is necessary for the tool to cut. The harder the material, the smaller the clearance angle should be.

The wedge angle affects the cutting force. If it is large, this results in a stable cutting edge but also higher cutting forces. A cutting edge with a small wedge angle, on the other hand, is sharper and more unstable.

The cutting angle determines how the swarf is removed. When machining soft, long-chipping materials, the machinist chooses a large cutting angle.

Manufacturing processes

| Manufacturing process main group | Subgroup (technology) |

|---|---|

| Manufacturing processes for primary shaping | Casting, 3D printing |

| Manufacturing processes for reforging | Rolling, forging, extruding |

| Manufacturing processes for separating | Cutting, drilling, milling |

| Manufacturing processes for joining | Soldering, welding |

| Manufacturing processes for coating | Painting, powder coating |

| Manufacturing process: material properties | Sintering, freezing, irradiation |

What is a machining manufacturing process?

When machining, the machinist can process the workpiece very precisely. Cutting tools from Gühring are therefore primarily used where perfect surfaces are required: in the automotive industry, aerospace and mechanical engineering.

Metalworking

Metal working plays a major role in machining technology because many parts for machines and constructions are made of metal and have to be machined. In the field of metal working there are two options: Cutting processes, such as milling and drilling, and non-cutting processes including casting and punching as examples.

Metal working places particularly high demands on machines. For this reason, Gühring tools can be used on state-of-the-art lathes and are particularly suitable for CNC metal working.

With customers. For customers.

In BEST PRACTICE 2025, you can read genuine success stories from the field as well as machining tips, tool recommendations and cutting data for your manufacturing success.

Simply register – and you will receive this machining guide directly and free of charge for download!