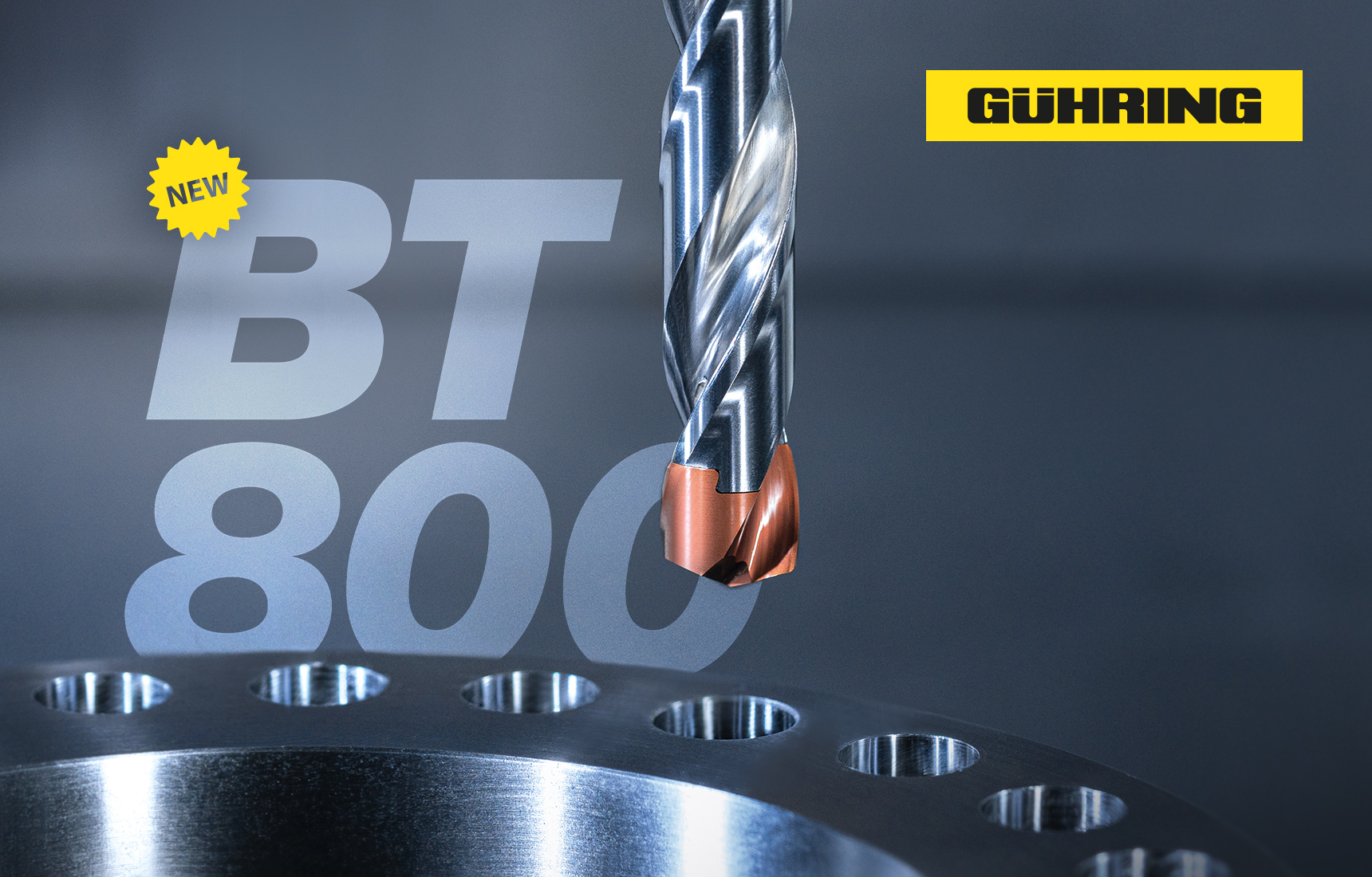

With the BT 800, Gühring is launching a high-performance replaceable head drilling system with bayonet lock, which is particularly impressive in medium to large diameters from Ø 14 mm due to its cost-effectiveness, flexibility and tool life.

When it comes to cost per part, every single parameter counts: Tool costs, set-up times and process reliability determine the efficiency of production. With the new BT 800 replaceable head drilling system, Gühring addresses precisely these points – and offers an economical and high-performance alternative to conventional solid carbide drills.

Modular system with solid carbide performance

The BT 800 combines two properties that are often mutually exclusive: the wear resistance of a solid carbide tool with the modular flexibility of a replaceable head system. This is made possible by the innovative bayonet interface – the centrepiece of the BT 800 – which stands for maximum clamping force, precision and repeat accuracy. Whether material change, component variation or process optimisation: Thanks to its modular design, the BT 800 can be quickly and easily adapted to different requirements – by changing the drill head directly in the machine without removing the carrier.

Cost efficiency for large diameters

The system fully utilises its economic advantages, especially for diameters from Ø 14 mm. Only the drill head is replaced when worn – this not only lowers tool costs, but also reduces warehousing and capital commitment.

Focus on productivity and flexibility

The option of combining different drill heads on one carrier shaft ensures a high degree of flexibility for changing requirements and materials. Heads can be changed quickly and safely – an advantage that reduces set-up times and increases machine availability. Another plus point: Gühring offers a closed tool cycle for the BT 800, including regrinding (up to twice) and a recycling service. This not only reduces costs, but also conserves resources.

Programme and technical features

This modular system will be launched in June 2025 with two holders for the Ø range 16.00 – 26.00 mm for drilling depths of 3xD and 5xD. Narrowly stepped Ø steps (in 0.1 mm increments) enable good guidance and increase the stability of the tool. The drill head with Persistum coating was specially developed for steel machining in the Ø range 16.00 – 26.00 mm. The range will be expanded in September 2025 with holder sizes 1.5xD, 8xD and 12xD as well as a Pilotier drill head with internal cooling for 4-fold cooling.

At a glance: The modular drilling system that can do more

- Wear-resistant like solid carbide

Solid carbide drill head for maximum tool life in demanding applications. - As flexible as a modular system

One carrier – many possibilities: Quickly convert to changing materials & geometries. - Quick tool change

Thanks to the bayonet interface directly in the machine – without removing the carrier. - Economical from Ø 14 mm

Significantly lower acquisition costs compared to monolithic solid carbide drills. - Sustainable in the Gühring cycle

Drill head can be reground up to 2× and is fully recyclable.

You might also be interested in:

Carbon masks save sports stars: customised high-tech orthoses with precision from Gühring

Especially for a team’s top performers, an injury due to a broken nose or cheekbone is catastrophic. This is precisely when Malzkorn’s product comes into play: carbon fiber-reinforced face masks for elite athletes.

150 % longer tool life: the interchangeable head drilling system for maximum cost-effectiveness

Modular drilling systems enable quick head changes within the machine – but if process reliability is lacking, the time savings can quickly become negligible. The BT 800 demonstrates that simple handling and performance don’t have to be mutually exclusive.

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.