Machining demo

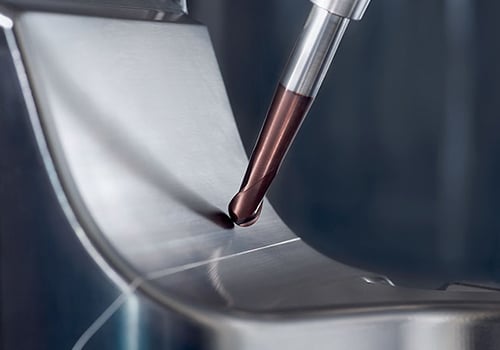

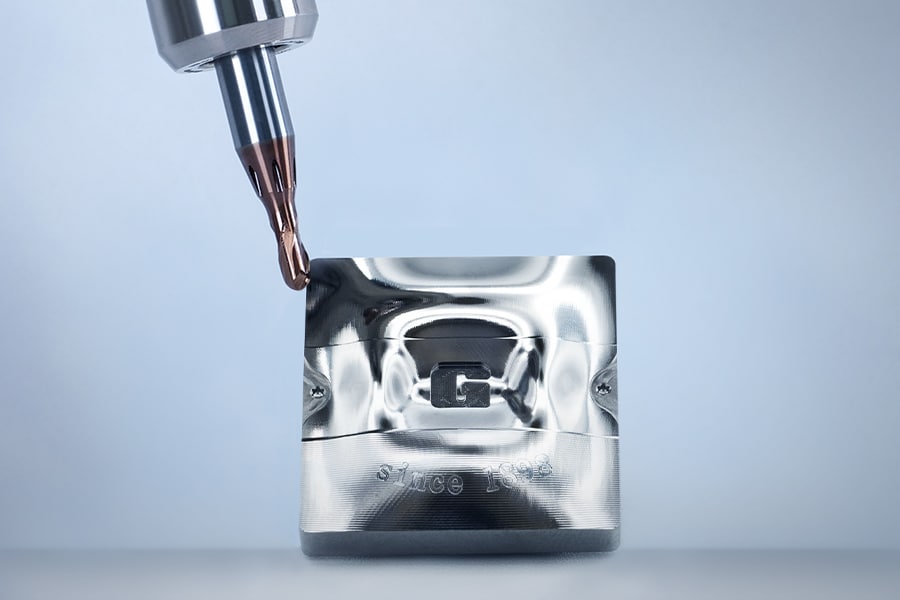

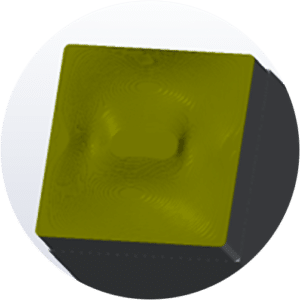

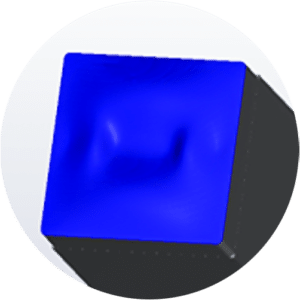

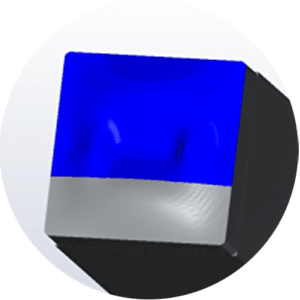

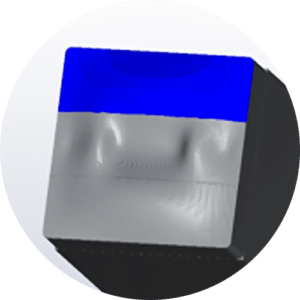

A perfect finish with G-mold µ

The tools from the new G-Mold range promise component surfaces of the highest possible quality. But can they also live up to this promise in practice? Gühring demonstrates its expertise in mould and die with a demo component.

Downloads / Links

From raw material to a finished component

Precision is crucial in the field of mould and die. Our G-Mold machining demo will show you how to achieve this: By selecting the right tool and the ideal parameters, we achieve perfect surfaces.

General information

- Type of machine: Kern micro

- CAM software: Tebis V4.1 R7

- Holders: Gühring GM300 4475 11.040 / HSK-E 40

- Sealed high-precision collets art. no. 4575

- Material: Stavax ESR with 55 +/-1HRC

- Component designation: G-mold surface demo

All processing steps at a glance

The following tables show all processing steps needed to manufacture the component, including machining parameters, cutting values and tool selection.

|

|

|

|

|

|

|---|---|---|---|---|---|

| Application | trimming ouiter contour | roughing completely | semi-finishing section 1-3 | finishing section 1-2 | fine-finishing |

| Strategy | contour milling | contour parallel | Axis parallel | Axis parallel | Axis parallel |

| Axis | 3 | 3 | 3+2 | 3+2 | 3+2 |

| Tools | G-Mold 65 U | G-Mold 65 T | G-Mold μ65 B | G-Mold μ65 B | G-Mold μ65 B |

| Article | 6943 6,000 | 6837 4,005 | 6815 3,000 | 6815 3,000 | 6815 3,000 |

| Type | Ratio Endmill | Torus-Endmill | Ball nose profile cutter | Ball nose profile cutter | Ball nose profile cutter |

| Ø | 6,0 mm | 4,0 mm | 3,0 mm | 3,0 mm | 3,0 mm |

| Radius | – | 0,5 mm | 1,5 mm | 1,5 mm | 1,5 mm |

| Teeth | 4 | 4 | 2 | 2 | 2 |

| n (U/min) | 6366 | 8355 | 21000 | 21000 | 32000 |

| Vc (m/min) | 120 | 105 | 198 | 198 | 302 |

| vf (mm/min) | 254 | 1003 | 2100 | 2100 | 320 |

| fz (mm) | 0,010 | 0,03 | 0,050 | 0,050 | 0,005 |

| ae (mm) | 1 | 2 | 0,25 | 0,05 | 0,005 |

| ap (mm) | 10 | 0,1 | 0,045 | 0,05 | 0,005 |

| Allowance ae/ap | – | 0,1 | 0,055 | 0,005 | 0 |

| Coolant | Air | Air | Air | Emulsion | Emulsion |

| Time | 00:02:30 | 00:21:14 | 00:05:35 | 00:17:40 | 05:20:51 |

| optical surface quality measurement Alicona | – | – | Rz 4,64 Ra 1,111 |

Rz 0,60 Ra 0,118 |

Rz 0,39 Ra 0,068 |

|

|

|

|

||

|---|---|---|---|---|---|

| Application | side pockets | pre-drilling Torx T4 | sinking Torx T4 | Torx T4 milling | |

| Strategy | pocket milling | drilling | sinking | Helix contour | |

| Axis | 3 | 3 | 3 | 3 | |

| Tools | G-Mold 65 T | RT 100 H Mikro | NC spotting drills 120° | Micro-precision milling cutters MicroMill μ 55 U | |

| Artikel | 6837 4,005 | 7053 0,900 | 6028 3,000 | 6829 0,202 | |

| Type | Torus-Endmill | micro-precision drill | NC spotting drill | Micro Endmill | |

| Ø | 4,0 mm | 0,9 mm | 3,0 mm | 0,2 mm | |

| Radius | 0,5 mm | – | – | 0 | |

| Teeth | 4 | 2 | 2 | 3 | |

| n (U/min) | 3500 | 10610 | 2122 | 31831 | |

| Vc (m/min) | 44 | 30 | 20 | 20 | |

| vf (mm/min) | 280 | 154 | 21 | 94 | |

| fz (mm) | 0,020 | 0,007 | 0,005 | 0,001 | |

| ae (mm) | 1 | – | – | 0,2 | |

| ap (mm) | 0,5 | 0,85 | 0,10 | 0,01 | |

| Allowance ae/ap | – | – | – | – | |

| Cooling | Air | Air | Emulsion | Air | |

| Time | 00:00:58 | 00:00:08 | 00:00:12 | 00:07:03 | |

| Optical surface quality measurement Alicona | – | – | – | – |

Tool & mould making

Shaping the future with tools from Gühring

CAD & cutting data

We provide you with cutting data for your application for download.

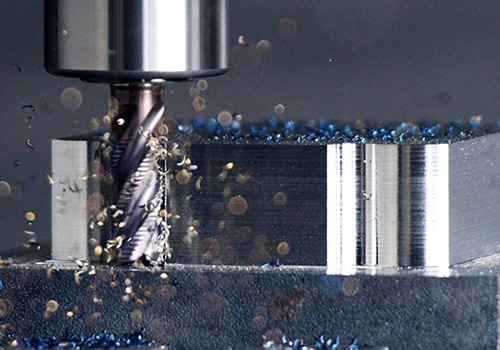

Milling tools

With these milling cutters, chips fly exactly how you want them to