Longer tool life, shorter machining times: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has opted for modern modular drills that are not only simpler to handle but also offer outstanding performance.

Content

Efficient metalworking with modular drilling systems

Challenges when changing drill heads

Quick change thanks to bayonet lock

Successful test use in manufacturing

65 % more tool life and reduced machining times

Tool tip: BT 800 – the better choice

Efficient metalworking with modular drilling systems

From individual parts and small series production to the finishing and reworking of metal parts: The company Kurt Metallverarbeitung from Remscheid manufactures various components for large-scale industry, such as spare parts for presses, cranes or excavators. Reliable tools that deliver the best machining results and maximum efficiency are essential. This is why the company focusses on modular drilling systems that impress with their high flexibility and savings potential.

Challenges when changing drill heads

However, when it comes to the practical application of modular drills, there is one crucial component that must not be missing: easy handling when changing the drill head. Director Samet Kurt also knows this: “Before the BT 800 from Gühring, we were using a competitor’s modular drilling system, which also allows drill heads to be changed directly in the machine without a screw.”

In this system, the drill head and carrier were connected using assembly keys with slotted engagement points. However, practical experience revealed shortcomings: “The drill head often got stuck in the tapered interface. Because it then had to be removed with a lot of force, it was easy to slip and damage the sheath,” recalls Samet Kurt. “Some drill heads were unusable after the change.”

Quick change thanks to bayonet lock

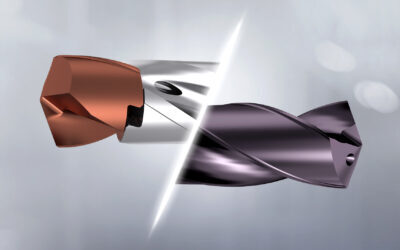

Gühring sales representative Ralf Hirschfeld then presented his customer with the modern BT 800 interchangeable head drilling system, a further development in the field of modular drills. The centrepiece of the BT 800 is the wear-resistant bayonet interface.

Compared to the previous system, the mounting key now engages in the flute, enabling the drill head to be changed quickly, precisely and safely without damaging the cutting head. The head is securely clamped without any play with a simple rotary movement – this not only increases safety, but also significantly minimises downtimes and set-up times.

Successful test use in manufacturing

Samet Kurt tests the modular solution while drilling a cog made from C45 quenched and tempered steel (1.0503), which will later be used in disc cutters. The through-holes with a depth of 10 mm were milled on a Haas VF-1 – ideal for use with the BT 800 interchangeable head drill. The result is convincing across the board: “The quick-change system from Gühring is simply better,” says Kurt. “There are no problems when changing the drill heads – handling is simple and safe.”

There are no problems when changing the drill heads – handling is simple and safe.

65 % more tool life and reduced machining times

But it’s not just the operation that is impressive: the BT 800 modular drill also sets new scales in terms of performance. “We were able to increase the tool life by 65% and reduce the machining time by more than half,” reports Samet Kurt. Ralf Hirschfeld adds: “The easy handling, long tool life and strong performance make the BT 800 a real economical alternative to solid carbide drills – especially in the field of economical metalworking with modular drilling systems.”

|

Competition |

Gühring | |

| Tool | Modular drill, Ø 17,5 mm | BT 800, Ø 17,5 mm |

| Component | Cog | Cog |

| Material | C45 (1.0503) | C45 (1.0503) |

| Cutting speed | Vc = 54 m/min | Vc = 94 m/min |

| Feed rate | f = 0,24 mm/rev | f = 0,32 mm/rev |

| Tool life | 100 parts | 165 parts |

Tool tip: BT 800 – the better choice

Modular interchangeable head drilling system

BT 800

for quick head change and high efficiency

The BT 800 allows you to use different drill heads on a standardised steel cutting body. This allows you to quickly adapt the tools to different materials or machining requirements.

Your advantages with the BT 800:

- Quick and easy handling in combination with a long tool life and high performance

- Economical alternative to solid carbide drills

- Minimisation of set-up times

BT 800 in the online shop

You might also be interested in

Carbon masks save sports stars: customised high-tech orthoses with precision from Gühring

Especially for a team’s top performers, an injury due to a broken nose or cheekbone is catastrophic. This is precisely when Malzkorn’s product comes into play: carbon fiber-reinforced face masks for elite athletes.

150 % longer tool life: the interchangeable head drilling system for maximum cost-effectiveness

Modular drilling systems enable quick head changes within the machine – but if process reliability is lacking, the time savings can quickly become negligible. The BT 800 demonstrates that simple handling and performance don’t have to be mutually exclusive.

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.