Modular drilling systems offer a wide range of potential savings, from the more cost-effective replacement of new tools to the reduction of tool stocks and warehousing costs. We have summarised the top 3 advantages of modular tools for you.

Content

What are modular drilling systems?

3 advantages of modular drilling systems

Conclusion: Why modular drilling systems are worthwhile

Tool tip: BT 800 – the better choice

What are modular drilling systems?

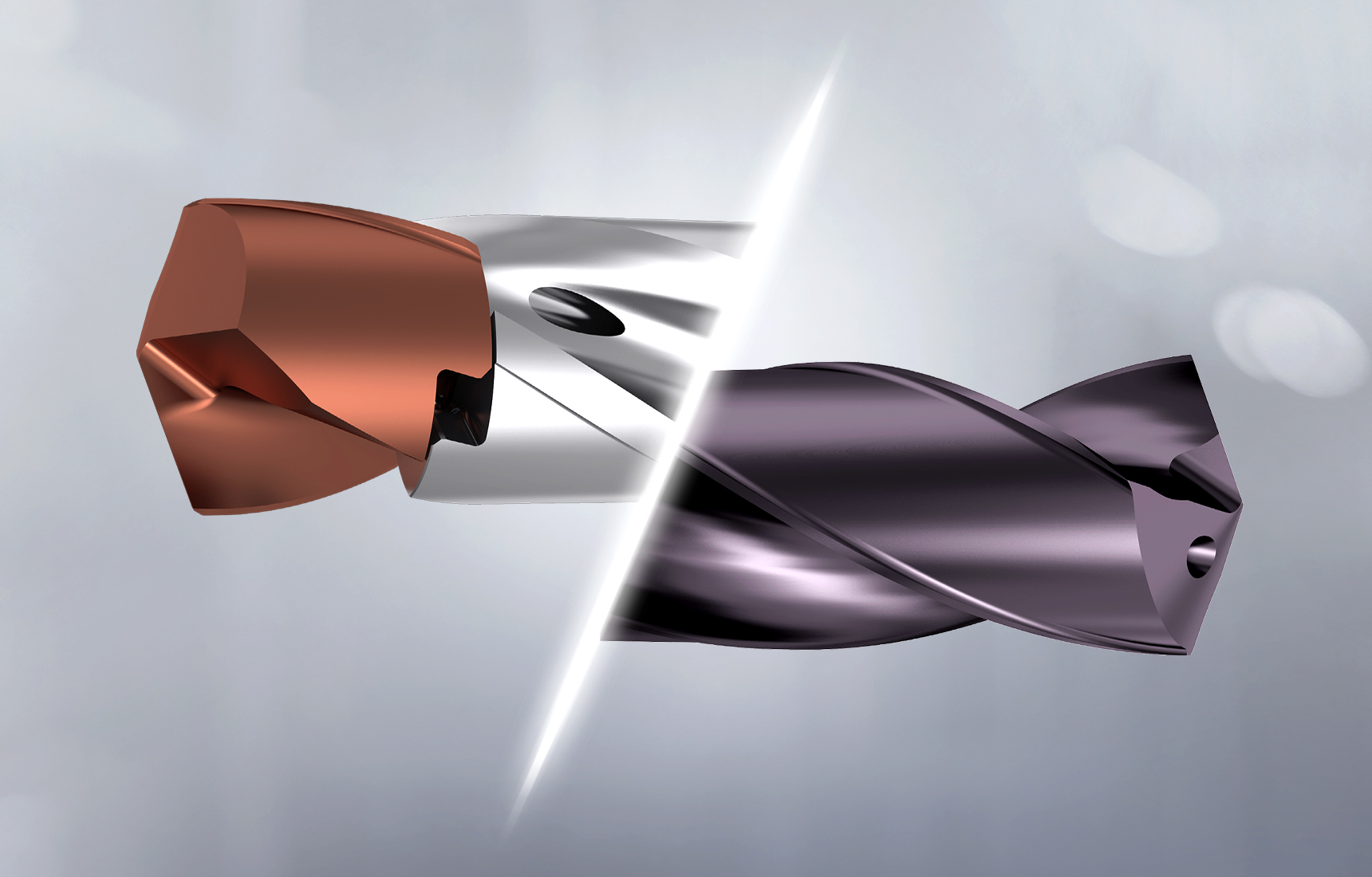

Modular drills are tools that consist of several interchangeable components, typically a drill head and a shank. These two components are connected via an interface and can be flexibly combined and exchanged. With the new BT 800, Gühring now has an innovative modular drilling system in its programme. Modular tools have a number of advantages over monolithic tools, which consist of a single continuous piece of material without interchangeable components. You can find out what these are here.

3 advantages of modular drilling systems

Advantage 1: Greater economy

Especially in large diameters, solid carbide drills are expensive to purchase, often without their performance being utilised at all. The BT 800 drilling system consists of a steel cutting body and replaceable solid carbide drill heads. This design ensures that you get an inexpensive tool with solid carbide performance – an economical alternative to solid carbide drills. The BT 800 modular system is more economical to purchase, especially for diameters > 14 mm. The BT 800 from Gühring promises simple, fast handling in combination with a long tool life and high performance.

Advantage 2: High flexibility

A modular drilling system enables the use of different drill heads on a standardised carrier. This allows you to quickly adapt the tools to different materials or processing requirements. Customised solutions are also possible, as the drill heads of the BT 800 can be flexibly adapted to your individual requirements in addition to the standard designs. As a result, you benefit from unlimited design freedom and maximum performance.

Advantage 3: Time and cost savings

With modular systems, only the drill head needs to be replaced when worn, not the entire tool. This reduces tooling costs compared to solid carbide drills. In addition, the drill head of the BT 800 can be reground up to two times. A modular drilling system also reduces capital commitment, storage costs and logistics costs. Instead of keeping several different tools in stock, it is sufficient to only have the required drill heads in stock. You also save on set-up times with a modular tool: the BT 800 interchangeable head is changed directly in the machine, which is significantly faster than changing a monolithic drill. This minimises your tool set-up times and productivity.

Conclusion: Why modular drilling systems are worthwhile

Modular drilling systems such as the BT 800 from Gühring impress with an intelligent combination of economy, flexibility and efficiency. They enable the use of high-quality solid carbide drill heads at significantly lower costs, as only the part of the tool that is prone to wear needs to be replaced. At the same time, they can be flexibly adapted to different applications – be it through the quick change of drill heads or customised special solutions. Modular systems also offer clear advantages in terms of time and cost savings: lower storage requirements, reduced set-up times and simpler handling directly at the machine. Modular drilling systems are the ideal solution for anyone looking for maximum performance with minimum effort.

Tool tip: BT 800 – the better choice

Modular interchangeable head drilling system

BT 800

for quick head change and high economic efficiency

The BT 800 allows you to use different drill heads on a standardised steel cutting body. This allows you to quickly adapt the tools to different materials or machining requirements.

Your advantages with the BT 800:

- Quick and easy handling in combination with a long tool life and high performance

- Economical alternative to solid carbide drills

- Minimisation of set-up times

You might also be interested in:

Carbon masks save sports stars: customised high-tech orthoses with precision from Gühring

Especially for a team’s top performers, an injury due to a broken nose or cheekbone is catastrophic. This is precisely when Malzkorn’s product comes into play: carbon fiber-reinforced face masks for elite athletes.

150 % longer tool life: the interchangeable head drilling system for maximum cost-effectiveness

Modular drilling systems enable quick head changes within the machine – but if process reliability is lacking, the time savings can quickly become negligible. The BT 800 demonstrates that simple handling and performance don’t have to be mutually exclusive.

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.