When it comes to demand for high-quality surfaces, excellent hole qualities and tight diameter tolerances, the HR 500 high-performance reamer has been raising the bar for years. Gühring is now creating the next sensation by expanding the product’s diameter range by +-0.05 mm increments. The result: With the new fixed-size reamers in 5µ increments, Gühring covers all tolerance ranges with a precision-fit.

If you’d like to avoid using an expensive special tool for producing tight tolerances outside the H7 fit system, then opt for a reamer from one of our fixed sizes. Conventional models only offer dimensions in 1/100 increments and ± 0.03 mm in their range. The result? The reamers are only suitable to a limited extent.

This is now set to change with Gühring: Thanks to new fixed-size reamers from ± 0.05 mm and dimensions in 5μ increments, Gühring is closing the gap in the market and covering numerous tolerances even outside the H7 class. And it does this with a great deal of precision as standard – without making any compromises or using custom-made products. As a result, customers benefit from over 100% more wear buffer and double the tool lives in selected fits when they purchase one of these high-performance reamers.

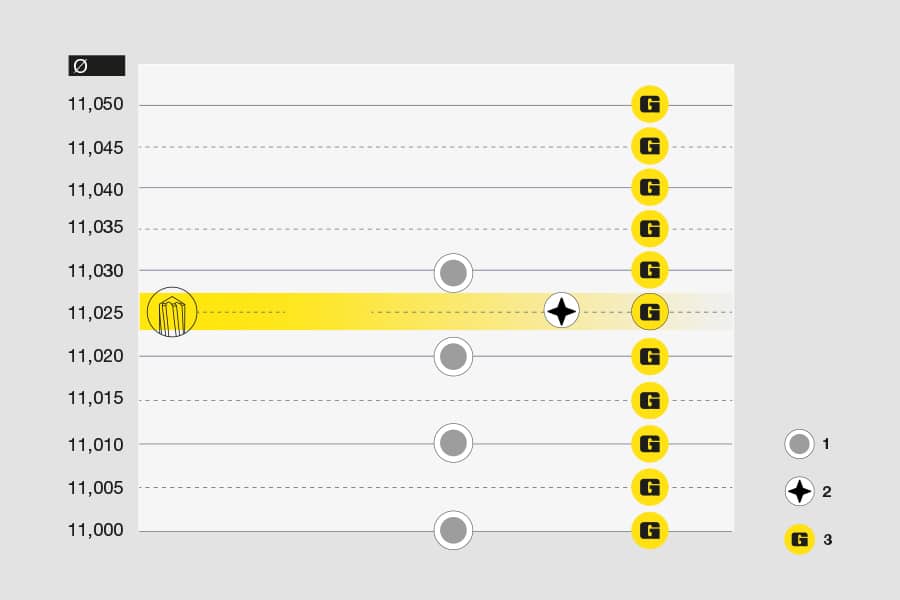

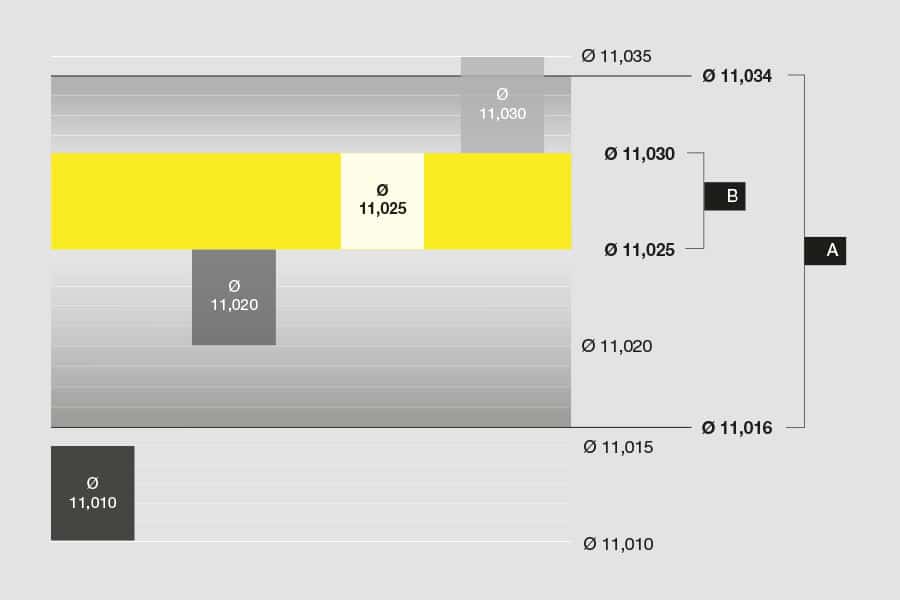

Example of fit: Perfectly within tolerance

The new intermediate dimensions for the HR 500 high-performance reamer in 5μ increments cover all tolerance ranges with high precision – for 125% more reaming performance. Using the example of tolerance 11 F7, we will now demonstrate what this means for your tool selection:

Ø 11.01: The reamer does not fall within the required tolerance range of the hole. The hole is too small.

Ø 11.02: The reamer falls within the required tolerance range of the hole. However, the wear buffer for the lower tolerance variable is only 0.004 µ. The tool wears prematurely, the hole is too small.

Ø 11.03: The reamer falls within the required tolerance range of the hole, but exceeds the upper tolerance variable. Risk of the hole being too large.

Ø 11.025 (SOLUTION): With the new standard programme in the 5/1000 range, Gühring covers all tolerance ranges with a precise fit. This results in article #1675 11.025

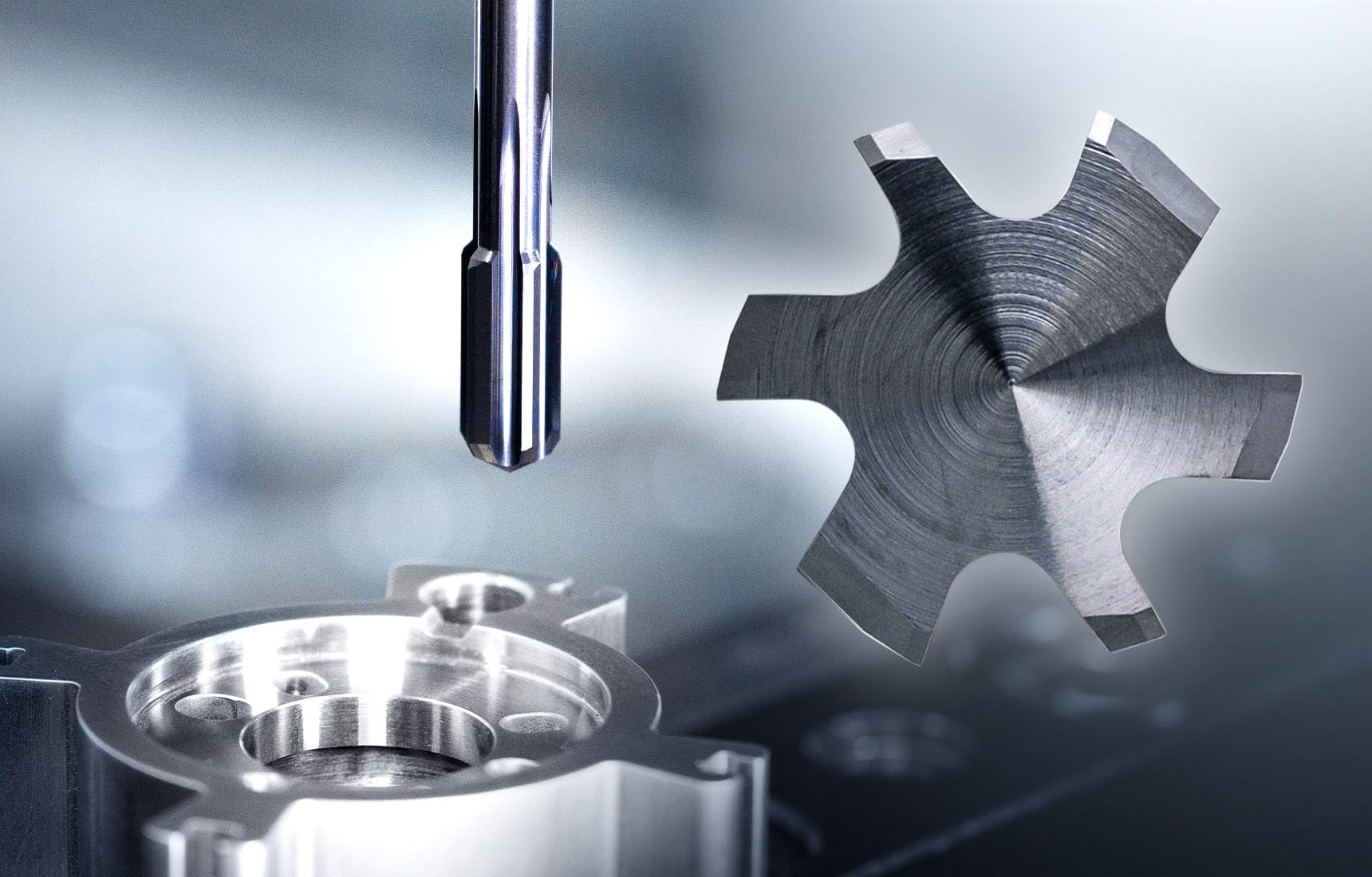

HR 500: Maximum precision

The HR 500 high-performance tool has been on the market for 20 years and no other conventional machine or NC reamer has come close to reaching its level of performance. Made exclusively in Baden-Württemberg, this successful product incorporates a great deal of expertise as we work hard to continuously optimise and enhance its concept and guarantee the highest production quality.

The product’s high performance is based on a combination of cutting edge geometry, the use of a special carbide and the coating. The universal use of these reamers allows them to be used in a wide range of materials, guaranteeing you maximum flexibility in your projects. The HR 500 family also includes tool variants for almost all materials.

How you benefit from the new fixed-size reamers

- precise reamers without compromises or expensive custom-made products

- 100% more wear buffer and longer tool lives thanks to finer increments

- programme covers numerous tolerances even outside the H7 range

- universally applicable in a wide range of materials

A number of testimonials from our customers are proof of this result: Thanks to high feed and cutting speeds at low cutting depths, the HR 500 achieves perfect machining results with maximum economic efficiency. In some cases, your investment in an HR 500 will be paid off after just 100 holes compared to conventional reamers.

Technical advice and support are also available quickly and directly via our service hotline 00800 2607 2607 We can also be reached on WhatsApp: +49 172 658 53 53. Save the number!

You might also be interested in:

Universal and unbeatable: double service life with the HR 500

Best hole qualities, tight tolerances, maximum precision: these are the key factors in the manufacture of mould inserts made of hardened steel. This customer relies on high-performance reamers from Gühring’s HR 500 range.

Six times higher metal removal rate: New micro-precision milling cutter for ISO-N materials

The RF 100 AL Micro offers an outstanding combination of precision, efficiency and process reliability, making it the first choice when machining aluminium, copper and brass. With its innovative properties this tool raises the bar for micro-machining.

With three cutting edges, you can create a 180° hole base faster than ever before

While competitors rely on two cutting edges in their 180° flat drills, Gühring is launching a three-fluted tool. And to great success: The FB 200 U excels with up to 50% higher cutting values, process reliability and better hole quality.