Interchangeable head drilling system

For quick head changes and high cost-effectiveness

The BT 800 modular drilling system offers a cost-effective and flexible solution for drilling diameters from 10 mm: Thanks to its wear-resistant bayonet interface, easy-cutting geometry and long tool life, the BT 800 enables process-reliable high-performance drilling with lower feed forces. With diameters from 10.0 to 26.0 mm, several length variants and up to two regrinding cycles, it combines precision, durability and easy handling in one system.

Flexible drilling with interchangeable drill heads

BT 800 is the better choice

Especially from Ø > 14 mm, the BT 800 modular system is more cost-effective than using monolithic solid carbide drills. Only the drill head needs to be replaced in the event of wear and not the entire tool. This helps you reduce tool costs.

Changing pays off

The BT 800 enables different drill heads to be used on a single steel cutting body. This allows you to quickly adapt the tools to different materials or machining requirements.

Interchangeable head drilling system BT 800

Cost-effectiveness

The BT 800 is a modular drilling system with quick-change drill head thanks to bayonet interface. It offers high cost-effectiveness thanks to longer tool lives and reduced set-up times.

Your advantages with the BT 800:

- fast and easy handling combined with a long tool life and high performance

- economical alternative to solid carbide drills

- minimisation of set-up times

Comparison of the BT 800

![Comparison of feed forces [N] between BT 800 drill head (yellow) and competitor (grey) – BT 800 shows lower and more even feed force in the machining process Comparison of feed forces [N] between BT 800 drill head (yellow) and competitor (grey) – BT 800 shows lower and more even feed force in the machining process](https://guehring.com/wp-content/uploads/2025/05/GUE_wechselkopf-bohrsystem-vorschubkraefte.jpg)

Feed force [N]

1 = Competition, 2 = BT 800

Reduced feed forces

Compared to traditional modular drilling systems, the BT 800 enables machining with reduced feed forces thanks to its large, easy-to-cut rake angles.

Cutting data

- Diameter (Ø) 17.50 mm (5xD)

- Material 42CrMo4

- Cutting speed (Vc) 90 m/min

- Feed rate (f) 0.3 mm/rev

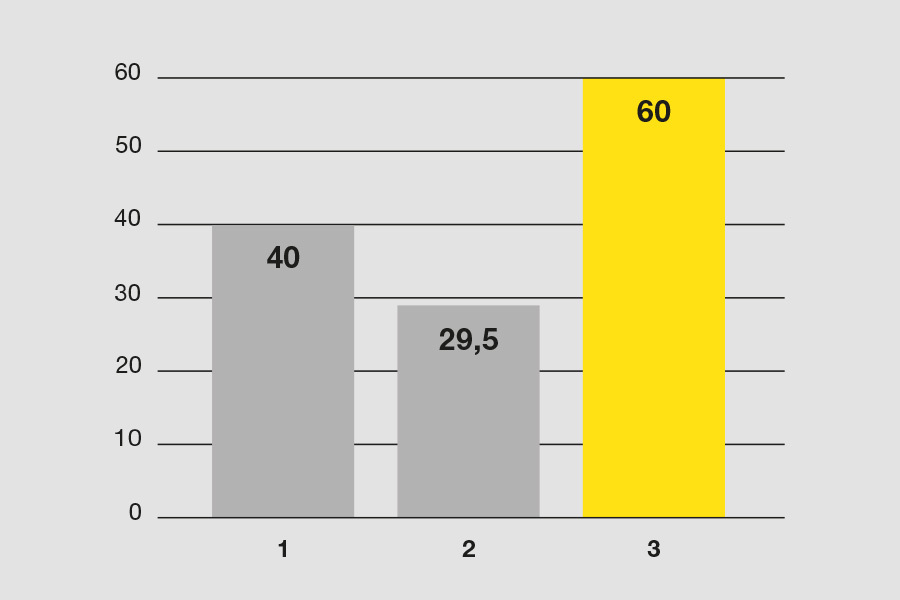

Tool life [m]

1 = Competition 1, 2 = Competition 2, 3 = BT 800

Minimal wear

Despite longer tool lives, the BT 800 exhibits significantly less corner wear compared to the competition.

Cutting data

- Diameter (Ø) 17.50 mm (5xD)

- Material 42CrMo4

- Cutting speed (Vc) 90 m/min

- Feed rate (f) 0.3 mm/rev

Flexibility & wear resistance

When drilling, the BT 800 combines the properties of carbide with the advantages of modular tools. Thanks to its simple, fast handling combined with a long tool life and good hole qualities, the modular system ensures shorter set-up times and more flexibility.

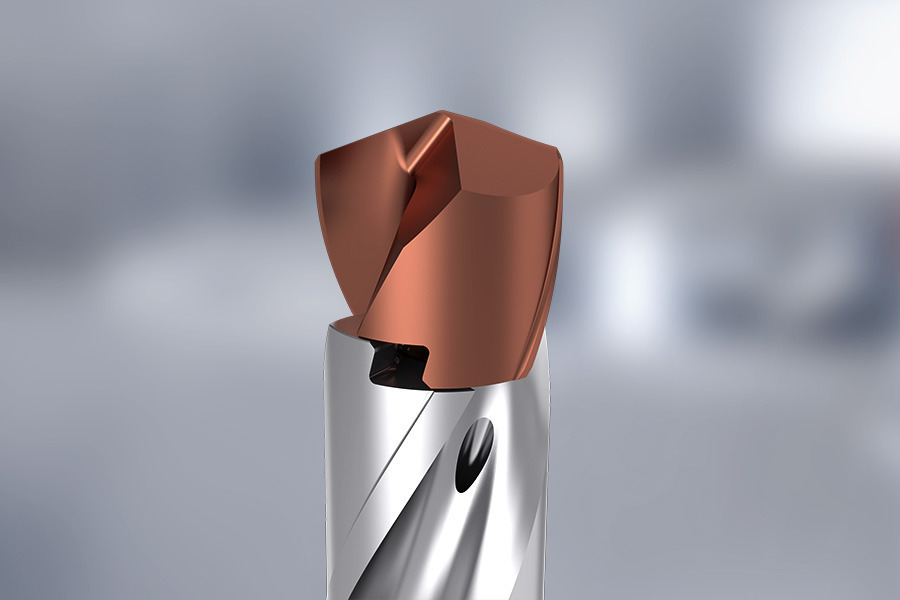

BT 800 P-P drill head

Carbide drill head for steel machining

The carbide drill head with the performance and geometry of a solid carbide drill has a premium cutting edge preparation for maximum tool life. Coordinated transitions from the drill head to the tool holder ensure safe chip removal without chip jams.

Your advantages with the BT 800:

- diameter range 10.0 to 26.0 mm

- increased wear resistance thanks to Persistum coating

- regrindable up to 2x

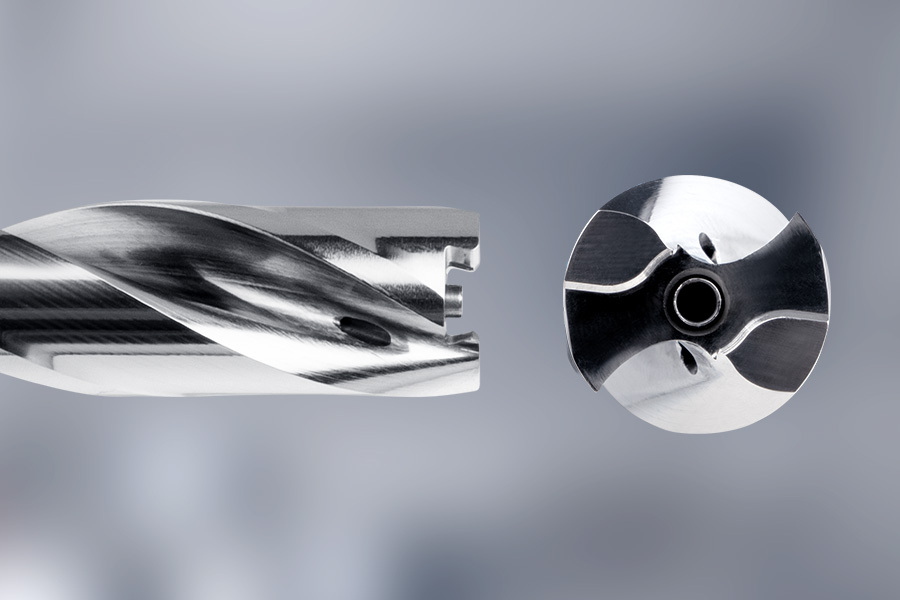

Key components of the modular drilling system

The BT 800 drilling system consists of a steel cutting body and interchangeable solid carbide drill heads. Thanks to these combination options, you save costs for more expensive solid carbide tools and space at stock level. Coordinated transitions from the drill head to the tool holder ensure safe chip removal without chip jams.

Steel holder for stable drilling processes

For different applications, only one shank is required. Polished flutes in the cutting body ensure reliable chip removal. In addition, tightly graduated Ø increments in the holder sizes enable improved tool guidance in the hole and increase the stability of the entire drilling system. This results in longer tool lives and better hole qualities.

Interchangeable drill head for maximum efficiency

The drill head offers the performance and geometry of a solid carbide tool. Large, easy-to-cut rake angles reduce feed forces, while coolant ducts with maximum cross-section and direct exit at the flute ensure targeted cooling lubrication.

Bayonet lock for quick change

At the heart of the BT 800 is the wear-resistant bayonet fixture, which impresses with its easy handling, while also enabling quick head changes directly in the machine.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationEasy assembly without screwing

While the drill head and tool holder are connected with a clamping screw on many standard modular drilling systems, the drill head on the BT 800 is clamped in the interface by a brief rotational movement with the mounting key. Furthermore, stable centring and contact surfaces ensure a secure and play-free clamping mechanism and optimum absorption of cutting forces.

Fine increments for all lengths

The BT 800 interchangeable head system is available from the start of sale in the lengths 3xD and 5xD. In the autumn, the diameter-length ratios 1.5xD, 8xD and 12xD will be added. The possible diameter ranges for all length variants are between 10.0 and 26.0 mm. We offer 0.1 mm increments.

Basics of modular drilling systems

What are modular drills?

Modular drills are tools consisting of several interchangeable components, typically a drill head and a shank. This design allows flexible adaptation to different materials and applications without the need to replace a complete drill.

Differences from monolithic drills

Modular tools have some advantages over monolithic tools that consist of a single continuous piece of material without interchangeable components. For example, the drill heads of modular tools can be easily changed in the machine, eliminating the need for multiple pre-calibration. The drill heads are easily replaced while the carrier can be reused.

Comparison table

Modular vs. monolithic drills

Modular drilling systems offer a wide range of savings potential, from cost-effective replacement of new tools to reduced tool inventory and inventory costs. The table below compares monolithic and modular tools in key features.

|

Modular drills |

Monolithic drills |

|

|---|---|---|

| Tooling costs | less, as only heads are replaced in the event of wear | higher, as complete drills are replaced when worn |

| Tool change cycle | quickly, as the shank remains in the machine and only the head is changed | slow, as tool adjustment is required |

| Warehousing costs | low, as fewer complete tools are required | higher, as more replacement tools are required |

| Sustainability | conserves resources thanks to reusable holders | increased material consumption due to complete tool replacement |

| Cost-effectiveness | more cost-effective, especially for larger diameters | less cost-effective with larger diameters |

| Regrindability | drill heads can be reground up to 2x | solid carbide tools can be reground several times |

| suitable for | large diameters, unstable conditions, wide material range | more stable conditions and specific materials |

Frequently asked questions about modular drilling systems

Why are modular drilling systems the future?

How often can the drill heads be reground?

The drill heads of our BT 800 interchangeable head drill can be reground up to two times. Customers have the option of handing over their drill heads to our professional regrind service.

What savings can be made by switching to modular drills?

How does changing the drill head work with the bayonet lock?

To attach a drill head to the holder, proceed as follows:

- Clean the interface with air pressure

- Oil the interfaces

- Insert the drill head into the interface so that it rests firmly on the tool holder

- Turn the drill head slightly clockwise

- Insert the key into the flute and tighten the drill head clockwise

- To remove, press the key firmly onto the drill head and turn it counterclockwise.

You can also find instructions on how to change the drill head in our BT 800 application recommendation.

Which companies benefit most from modular drilling systems?

RT 100 InoxPro

High-performance solid carbide drill for stainless steels and titanium alloys

RT 100 XF

Solid carbide drills for extreme machining rates and powerful machining

RF 100 Sharp

Our sharpest milling cutter for effective machining of soft, tough materials