RF 100 SPEED

HPC milling in steel and stainless steel – effective HPC machining

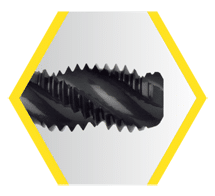

With the new RF 100 Speed, the sharpest and fastest HPC milling cutter in Guhring’s Ratio programme is available on the market. It distinguishes itself thanks to a steep helix of 48° and its unequal cutting edge distribution for a smooth and quiet cutting operation. The milling tools are available in various designs. The long option possesses chip breakers to break short chips and hence ensures a friction-free chip evacuation.

Machining record (1000 cm³ per min)!

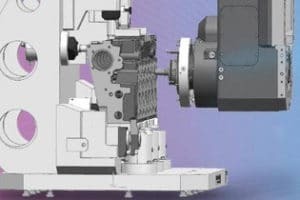

Gühring & Chiron

Gühring & Chiron – an unbeatable team! Together, the companies have set an unbelievable machining record: 1,000 cm³ of steel per min! The interplay of machine dynamics and milling stability makes this kind of machining rate possible and will make the hearts of those in mould-making, the aviation industry and the automotive industry beat faster.

The FZ16 S five axis single-spindle model from Chiron is designed to meet special accuracy requirements during 5-axis machining. In combination with the GTC (Gühring Trochoidal Cutting) RF 100 Speed Ratio milling cutter from Gühring, a removal rate of 1,000 cm³ steel (16MnCr5) per minute was achieved. The machining centre and milling cutters impressed with an outstanding performance in terms of dynamics and productivity. Chip breakers and extreme cutting length of the cutter ensure a soft cut and very quiet operation. Previous vibration analyses and the GTC milling strategy guarantee process stability, therefore resulting in more parts with the highest precision, particularly with HPC and rough milling.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationRF 100 Speed

RF 100 Speed: HPC milling in steel and VA

THE NEW GTC FORCE

RF 100 Speed with 5 and 7 cutting edges

Particularly when milling very tough materials, the cutting speed can only be increased to a limited extent if you also want to achieve process stability. Due to the increased number of cutting edges of the 5-cutting-edge and 7-cutting-edge RF 100 Speed, high removal rates can still be achieved in materials that are difficult to machine while maintaining process stability.

The 5- and 7-cutting-edge RF 100 Speed ratio milling cutter has now joined the Speed family and facilitates highly dynamic GTC machining at an ae of up to 10%. If the machine speed is restricted or the materials causes cutting speeds to be limited, the increased number of teeth ensures high feed rates and a long tool life. These models are particularly suitable for machining difficult-to-cut materials in stable conditions.

// High-performance roughing even at high cutting depths

// Maximum feed rates for high removal rates

// Highly dynamic GTC milling in tough stainless steels, special alloys and a wide range of steel and cast iron grades

RF 100 Speed P und M

The 5 and 7 Speed complement the established RF 100 Speed range with the material specialists P and M. These are suitable for GTC machining at an ae of up to 15%. Thanks to the high spiral angle of 48° with an unequal blade pitch for soft, quiet cutting and large flutes, the RF 100 Speed P and RF 100 Speed M ensure a low machine load and power consumption. The lower number of teeth offers maximum chip space for good chip removal. The milling tools are available in different versions. The long version has chip breakers to reduce the chips to short lengths, ensuring smooth chip removal. Large chip spaces on the face and improved thinning help to ensure reliable plunging. The enhanced corner protection chamfer and correction at the front protect the cutting edge – the most vulnerable part of the tool – from two sides, enabling the cutting edge to withstand heavier shear loads. This combination significantly extends the tool life of the tool.

More information on the RF 100 Speed

RF 100 Speed possesses the geometry required to do justice to materials such as tough, low- and high-alloyed steels as well as difficult-to-machine materials – especially in modern application technologies such as the HPC milling strategy.

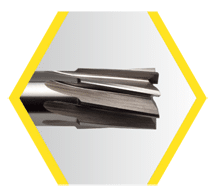

Double protection with corner protection chamfer and face correction

The tool has an optimised face geometry: Large face chip chambers and the improved web thinning allow process reliable plunging. Unequal cutting edge distribution ensures improved running smoothness and results in outstanding surface finish and long tool life. The optimised corner protection chamfer and face correction protect the cutting edge corner, the most sensitive part of the tool, from two sides so the cutting edge stands up well to even heavy shear loads. Thanks to this combination tool life is considerably improved.

Full slotting up to 0.8xD thanks to core stability

RF 100 Speed has a reinforced DIN shank for higher stability. Core stability creates more chip space in the frontal area making problem-free full slotting up to 0.8xD possible. Additionally the optimised face geometry makes helical plunging or oblique ramping possible.

Innovative chip breaker for HPC milling

With previous smooth cutting milling cutters applied in HPC strategies chips in the length of the ap (feed) are produced. Thus many chips are produced in a short period of time difficult to remove from the process. Chips remain on the workpiece and are difficult to evacuate. Thanks to the chip breaker the chips fall closer together, the evacuation is made easier. Especially with internal contour and cavities chips can be evacuated easier this way and therefore advantages in process reliability are gained. The light cutting operation significantly reduces machine load and increases volume output.

Application:

- HPC roughing: Dry machining in 42CrMo4 (1.7225 with 900 N/mm2)

- in HPC clamping chuck with PinLock extraction safety

- Cutting parameters:

ap: 60 mm ae: up to 1 mm

vc: 270 m/min S: 4300 min-1

fz: up to 0.21 mm vf: up to 3715 mm/min

Metal removal rate Q = 222 cm³/min - Tool life in excess of 278 min for roughing

DRILLING TOOLS

Sophisticated drill technology

THREADING TOOLS

Perfectly formed threading tools

MILLING CUTTERS

Near endless tool life