Sunday afternoon, sun shining over the stadium, 50,000 voices singing their hearts out. The ball bounces off the wet turf, flies through the air in a wide arc, two players race towards each other: one pulls his knee up slightly, the other countersinks his shoulder, both with tunnel vision on the ball. A dull “thud”, followed by a bright, barely audible “crack” – like breaking ice under heavy boots. A face contorted with pain, a hand instinctively shoots upwards. Blood slowly drips onto the turf. Nose: broken. Coach: distraught. Especially for key players in a team, an injury due to a broken nose or cheekbone is catastrophic. This is exactly where Malzkorn’s products come in: carbon fibre-reinforced face masks for top-level sport.

What looks like Batman is actually premier class orthopaedic technology. Carbon fibre-reinforced face masks allow millionaire players in the Bundesliga, NBA and NFL to continue playing despite facial injuries. They are individually adapted to the carrier’s face in sessions lasting several hours. The StepPower drill from Gühring shines in the final process step.

Video leads to collaboration

It all started with a video that Gühring sales representative Marcel Horn saw on social media. The video shows the manufacturing of a customised face mask for a player in the German Bundesliga. The nose that needed protection belonged to a footballer who had been injured during a match. In order to continue playing, he needed a mask that would protect his broken nose from further injury.

This is where Sebastian Malzkorn comes in. The camera follows the master orthopaedic technician as he places a custom-made carbon mask on the player’s face and adjusts it with a few final touches. Finally, he uses a twist drill to drill two holes in the mask on the right and left sides to secure it in place. To do this, he has to hold the mask in his hand and feel exactly when the drill breaks through the back. When Gühring sales representative Marcel Horn sees the video, he knows immediately that there is a better way.

He gets in touch with Sebastian Malzkorn, who, together with his brother Alexander Malzkorn, runs Sanitätshaus Malzkorn GmbH in Cologne in the fourth generation. With 45 employees across five locations, the company specialises in aids for people with physical disabilities, sports injuries or limitations following surgery. These aids include shoe insoles, orthoses and arm and leg prostheses.

Bad holes are expensive

Each of these parts is unique and made specifically for the patient. For the carbon mask, for example, Sebastian Malzkorn takes an impression of the patient’s face. “I always do this by hand, because the tactile aspect is incredibly important to me in order to get the best out of the product”, explains the master orthopaedic technician. “I have to feel the depth and palpate the area of the body. This ensures that the mask fits snugly on the face and does not bother the wearer.” The impression is then cast into a model, over which the carbon undergoes vacuum moulding. The entire process takes about 16 hours, and only at the end are the side holes drilled into the mask.

“The holes must, of course, function properly and look neat”, notes sales representative Marcel Horn. “There’s nothing worse than putting many hours of work into a component only to have it end up in the bin.” But that is exactly what has happened time and again in the past. Malzkorn often uses sophisticated materials such as carbon or glass fibre-reinforced plastics as base materials because they are very light yet offer a high level of protection for the face.

However, machining these materials can cause chipping and burrs on the hole, which then have to be laboriously ground down and countersunk. In the worst case, the previous drills were unable to produce a precise hole and the entire process had to be started again from scratch. This is particularly frustrating because Malzkorn GmbH supports international sports teams, for example in the field of American football, and NFL players are flown in especially for a mask.

From now on, only StepPower from Gühring

Fortunately, Gühring has the perfect solution for guaranteed burr-free holes by hand: the StepPower drill. This innovative twist drill is characterised by its stepped drill point. With its small pilot diameter and 2-stage diameter increase, the StepPower offers optimum piloting and centring properties. The steps drill the desired diameter piece by piece. The chips are broken into small individual chips by several main cutting edges. At the same time, the tool excels with high tool stability and excellent tool guidance with little effort. All these features ensure that the StepPower can be used to produce precise, circular holes and burr-free hole exits – while being easy to handle.

The major advantage for Malzkorn: With the StepPower, reworking is completely eliminated, resulting in enormous time savings. Sebastian Malzkorn was convinced from the start: From the very first hole drilled with the StepPower, we achieved perfect positioning for clean holes without chipping. Malzkorn now uses the step drill for drilling in all materials. For us, the StepPower is the all-round happy package.”

“From the very first hole drilled with StepPower, we achieved perfect positioning for clean drilling without chipping.”

“I can rely on the tool to work, which not only makes my everyday life easier, but also takes a lot of stress off me”, says Sebastian Malzkorn. “The handling is much easier; I can now simply position the component and drill a perfect hole in a single working step. That was never possible with the tools I used before.”

StepPower: The tool in detail

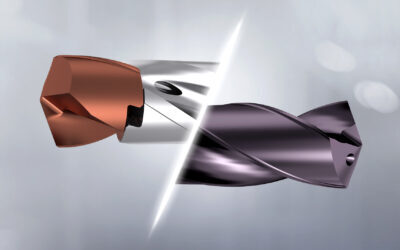

StepPower drill

Perfection in drilling by hand

The innovative design of the StepPower hand spiral drill ensures precise, circular holes and burr-free exit holes – and all this with remarkable ease of handling thanks to a single drilling tool. The special stepped drill point with a small pilot hole and two-stage diameter enlargement enables drilling without separate centring or pre-drilled hole.

Your advantages with the StepPower drill:

-

precise, circular holes with burr-free exits

-

no centring or pre-drilled hole required thanks to stepped geometry

-

ergonomic 3-flats shank for ideal power transmission

150 % longer tool life: the interchangeable head drilling system for maximum cost-effectiveness

Modular drilling systems enable quick head changes within the machine – but if process reliability is lacking, the time savings can quickly become negligible. The BT 800 demonstrates that simple handling and performance don’t have to be mutually exclusive.

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.