Best hole qualities, tight tolerances, maximum precision: these are the key factors in the manufacture of mould inserts made of hardened steel. Fritz Schmidt Metallgießerei GmbH & Co. KG relies on high-performance reamers from Gühring’s HR 500 range. This enables the Meckenheim-based company to double its tool life compared to a competitor’s reamers. And thanks to cutting speeds that are five times higher, it also saves valuable machining time.

Customers from various industries, such as medical technology and the automotive industry, rely on the high level of vertical integration at Fritz Schmidt Metallgießerei GmbH & Co. KG: Thanks to its in-house design, foundry, mould making and mechanical processing, the company offers tailor-made solutions in the field of aluminium die casting as well as for mould and plant engineering. The highest quality standards are a top priority.

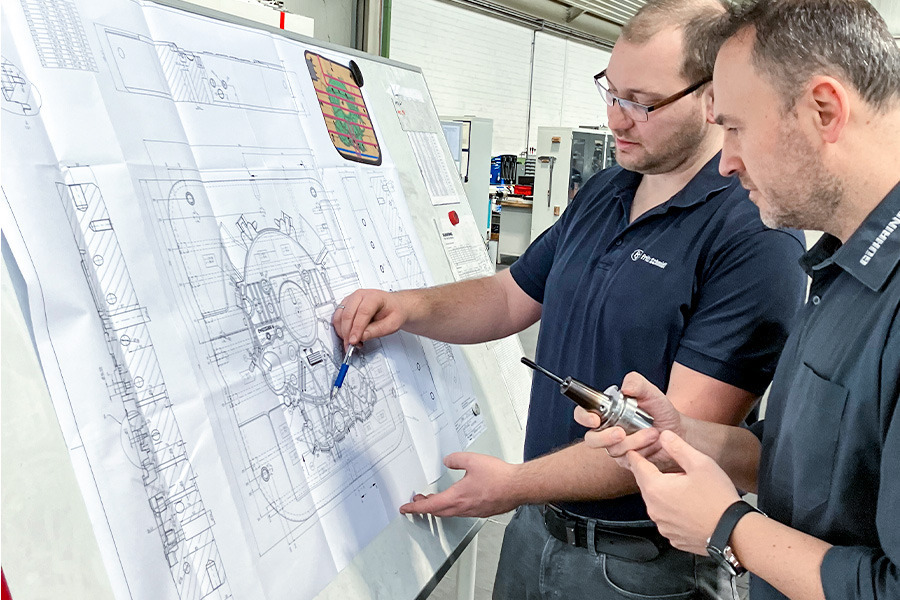

“We have been using various Gühring tools for years,” reports Fabian Hambach, deputy manager of toolmaking at Fritz Schmidt Metallgießerei GmbH & Co. KG: “In the last four years, we have significantly increased the number of Gühring tools, particularly in mould making.” This is an area where not only precision and process reliability are extremely important. Tight tolerances must also be adhered to in order to maintain the required contour accuracy. This is particularly true in the area of reaming, where manufacturing must be accurate to the micron.

Precision without compromise

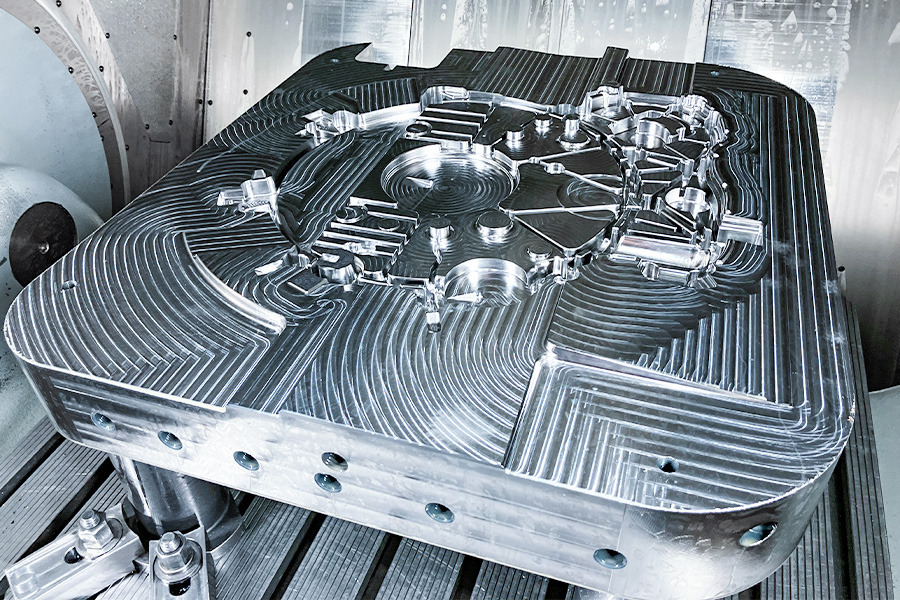

Reamers are also used in the production of mould inserts manufactured by the company. Extreme precision is required here, as these moulds define the outer contour and surface of the component produced in the die-casting process. This process enables the mass production of complex components made of aluminium alloys, which are used in the automotive industry, for example. The quality of many components therefore depends on the quality of a mould insert – Fritz Schmidt Metallgießerei GmbH & Co. KG has no room for compromise.

To drill holes of different diameters in the mould inserts, Fritz Schmidt Metallgießerei GmbH & Co. KG initially uses reamers from a competitor. However, the results are not entirely satisfactory: the service life is insufficient, resulting in high tool costs. Fabian Hambach then asks his long-standing contact at Gühring for advice: “We can do better than that,” says sales representative Marcel Horn – and recommends a high-performance reamer from the HR 500 range to his customer. “The HR 500 is one of the Gühring tools I would stake my reputation on,” says Marcel Horn. And soon the customer would share this opinion.

A mould insert is manufactured from hardened steel.

Maximum performance in hardened steel: a case for the HR 500

“Since we were looking for a reamer for these applications that also performs very well in hardened steel up to 50 HRC, the decision was quickly made in favour of the HR 500 Universal for through holes (item no.: 1686),” explains Marcel Horn. In addition to outstanding hole qualities and process reliability, the reamers also have to cope with very hard and wear-resistant material. Since liquid aluminium alloy is later injected into the mould under high pressure, the mould insert is exposed to high mechanical stresses and temperatures – and must not deform. For this reason, the company uses hardened steel (1.2399, 48-50 HCR), which can withstand these stresses.

Forging plans together: Fabian Hambach (Fritz Schmidt Metallgießerei GmbH & Co. KG) and Marcel Horn (Gühring).

A case for the HR 500 Universal: the high-performance solid carbide reamer not only demonstrates its strengths in steel, stainless steel, titanium and special alloys, but also in hardened steels up to 63 HRC. The TiAIN-nanoA coating ensures high wear protection, which in turn leads to long tool life. It is available in diameters ranging from 2 mm to 20 mm. During machining, the central coolant supply with outlet via oil grooves on the shank ensures optimum cooling and reliable chip removal in the through hole. In combination with the extreme feed and cutting speeds that can be achieved with the HR 500, users do not have to worry about process reliability.

Double service life, 5-fold faster cutting speeds

“We tried out the reamer and immediately achieved excellent results,” recalls Fabian Hambach. The high-performance reamer (Ø 10 mm) can machine 230 holes in mould inserts for the automotive industry, where the reamer previously used had reached the end of its service life after only 115 holes. But that’s not all: “Our original goal was to increase service life and process reliability,” reflects Fabian Hambach. “The fact that we have also become many times faster was a positive side effect.”

Instead of the previous cutting speed of V(c)= 10 m/min, the HR 500 easily achieves five times that speed: “The competitor’s tool couldn’t even come close to our cutting values,” summarises Marcel Horn. Thanks to the switch to high-performance reamers from the HR 500 range, Fritz Schmidt Metallgießerei GmbH & Co. KG has been able to significantly improve service life and machining times while maintaining the same surface quality and tolerances.

We tried out the reamer and immediately achieved excellent results

No more gaps

With the HR 500 range, Gühring offers standard high-performance reamers for all diameters from 1.95 mm to 76 mm. Customers benefit from short delivery times and a wide product portfolio: in addition to the version for universal applications, the standard range also includes the short HR 500 version for limited installation spaces and various material specialists, such as for applications in cast iron or aluminium.

While standard fixed dimensions are only available in a range of +/- 0.03 and in 10µ increments, Gühring is closing a significant market gap with this new addition: the Albstadt-based tool manufacturer is now also offering the fixed dimension series in a range of +/- 0.05 and in 5µ increments. This saves users high costs for special tools and also benefits them with over 100% more wear allowance and longer tool life.

HR 500: The tool in detail

HR 500 high-performance reamer

HR 500

Precision at the highest level

With the high-performance reamers from the HR 500 product family, Gühring offers a wide range of standard tools for all diameters from 1.95 to 76.00 mm. The HR 500 family also includes tool variants for almost all materials.

Your advantages with the HR 500:

- Innovative cutting geometry and cooling for controlled chip removal

- High process reliability thanks to high feed and cutting speeds

- Cost reduction through shorter cycle times, long tool life and fast availability

You might also be interested in:

New market standard: The perfect fit for any diameter range

Gühring is expanding the diameter range of its high-performance reamer, the HR 500, by dimensional increments of +-0.05 mm. The result: With the new fixed-size reamers in 5µ increments, Gühring covers all tolerance ranges with a precision-fit.

4000 components, instead of 40: Unbeatable tool lives with the high-performance reamer

KIPP was facing a challenge: Their cast-steel products need to be equipped with through-holes with µ-level precision. With the HR 500 high-performance reamer, KIPP no longer has to worry about poor dimensional accuracy or short tool lives.