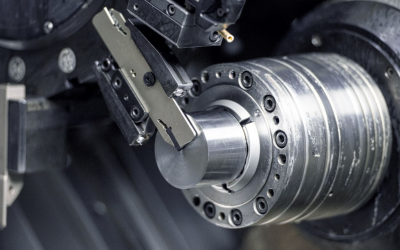

The system 222 parting off programme is complemented by a series of tool holders that have been specially developed for parting off on sliding headstock lathes and in confined spaces. Thanks to their special features, the tool holders enable convenient insert changes directly in the machine and ensure high process reliability.

Content

Problems with grooving on sliding headstock lathes

Convenient insert change in tight spaces

Tool holder with precision cooling for a high surface finish

Various designs for maximum stability

Fazit: Diese Vorteile bieten die Klemmhalter für Langdrehmaschinen

Conclusion: These are the advantages of tool holders for sliding headstock lathes

Problems with grooving on sliding headstock lathes

When grooving tools are used on sliding headstock lathes, there is a problem in many clamping situations: Space is often limited in the machine room of sliding headstock lathes. As a result, the tool is difficult to reach. In addition, many conventional tool holders are unusable for these machines due to their dimensions.

“The previous standard tool holders have a head length that is too long to be used on most sliding headstock lathes,” explains Marc Wiesner, Product Manager for grooving tools at Gühring. “That’s why we have significantly shortened the head length of this tool holder series.”

The tool holder offers maximum stability thanks to its shortened head length. It also has a newly developed clamping screw with Torx Plus on both sides. Together with a Torx Plus wrench with a reduced key length, this makes changing inserts much easier and can be done directly in the machine.

Convenient insert change in tight spaces

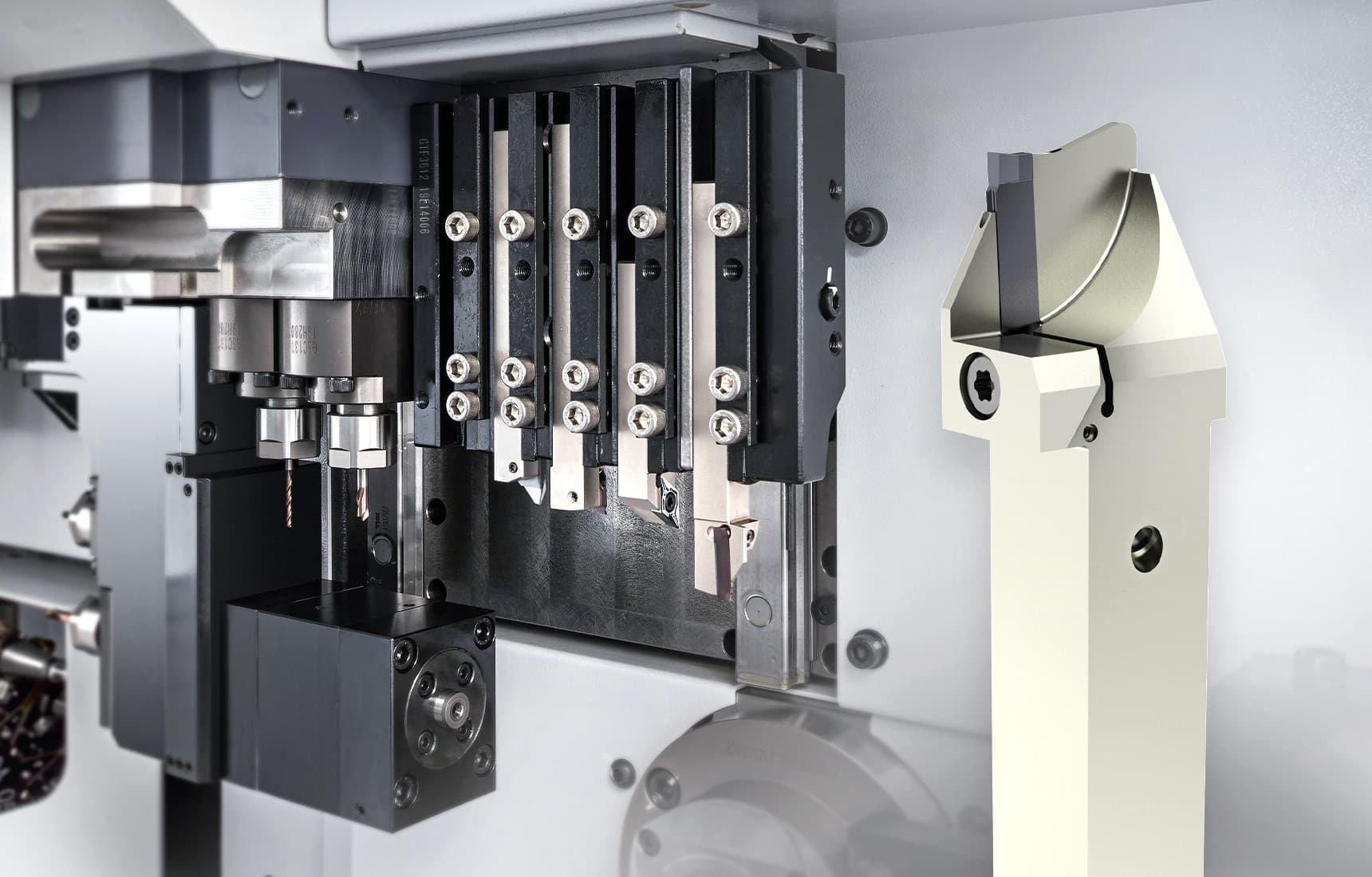

The animation shows an example of changing the parting off plate in a sliding headstock lathe. This shows the advantages of the tool holder: The compact design of the tool holder allows it to be clamped a long way so that the cutting edge is at approximately the same height as the other tools.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThis ensures stability when grooving, prevents interference contours and simplifies programming. The clamping screw can be reached with the shortened Torx wrench despite the close distance to the neighbouring square shank holder. The Torx Plus on both sides of the clamping screw also allows the screw to be operated from the other side. This makes changing inserts easy and convenient.

Tool holder with precision cooling for a high surface finish

The grooving depth and the maximum bar diameter of the tool holder have also been adapted to the requirements of parting off on sliding headstock lathes – for maximum stability and process reliability when parting off. In addition, the tool holder has precision cooling on the chip and clearance faces of the grooving inserts. This favours chip breakage, minimises heat generation and ensures consistently high performance even with demanding materials such as high-grade steel.

Various designs for maximum stability

The tool holders with short head lengths are available in the most common square sizes 10×10 mm, 12×12 mm and 16×16 mm, as well as the corresponding inch dimensions. All tool holders mentioned are available in left and right-hand designs with internal cooling and without internal cooling.

Conclusion: These are the advantages of tool holders for sliding headstock lathes

System 222 tool holders

For perfect surfaces when parting off high-grade steel

The new tool holder series from Gühring’s System 222 is specially tailored to the limited space available in sliding headstock lathes. Thanks to its shortened head length, a clamping screw with Torx Plus on both sides and compact design, it enables quick and convenient insert changes directly in the machine. The high stability supports reliable machining.

Your advantages with the system 222 tool holders

- Convenient insert change with limited space in the machine room

- Maximum stability when parting off

- Precision cooling on the chip and clearance faces of the grooving plates

You might also be interested in:

System 208: Precision and process reliability for sliding head turning technology

With the new System 208, Gühring is launching a grooving system that has been specially developed for sliding headstock lathes. It specifically meet the requirements for machining complex micro-turned parts.

30% more tool life: With this parting off plate you achieve maximum performance in high-grade steel

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

New feature: Reliable parting off in stainless steel with System 222

The System 222 for grooving and parting off has been expanded: With two cutting edges and a length of 22 mm, the new indexable insert is ideally suited for parting off the most common bar diameters made from stainless steel materials with a width of 3 mm.