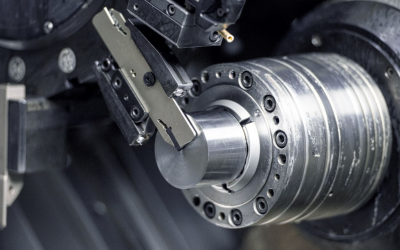

With the new System 208, Gühring is launching a grooving system that has been specially developed for sliding headstock lathes. Its special geometry, high interchangeability and proven service life advantages specifically meet the requirements for machining complex micro-turned parts.

Compact design for confined spaces

Sliding headstock lathes often operate in extremely confined spaces. This is exactly where System 208 comes in. The rhombic, ground indexable insert with two cutting edges is designed so that it can be used precisely even in small machines with bar feeders. With a maximum groovin depth of 8 mm, the system covers common machining operations from parting off to grooving and longitudinal turning.

For the user, this means a tool that covers a wide range of applications in a compact form without compromising on stability or accuracy. In field trials, the tools used in the 208 system showed increased tool life of up to 30 per cent compared to the competition. In addition to longer tool life, users benefited from shorter cycle times and more stable processes. For customers, this means fewer tool changes, lower part costs and stable series production.

High process reliability thanks to precise interface

A central feature of the System 208 is its high-precision interface with changeover accuracy of ±0.015 mm. This precision ensures that the cutting edges are positioned exactly after each insert change. In practice, this reduces set-up times and minimises scrap.

The newly developed clamping screw with double-sided Torx-Plus enables quick changes directly in the machine. This saves time during the ongoing process and makes handling easier for the operator.

Focus on customer benefits

The System 208 offers advantages for various industries:

- Medical sector: precise machining of intricate components, e.g. implants and instruments

- Electronics & robotics: high process reliability for small batches and high volume production

- Connector technology: reliable machining of demanding materials

In all these industries, the System 208 ensures higher machine availability, longer running times per tool and a reduction in the total cost per component.

What does the grooving programme consist of?

The System 208 programme comprises the following components:

- Precisely ground indexable inserts with nanoA-coating in five geometry variants (GE, GP, GR, GZ nutral & GZ R/L) for different machining operations with grooving depths up to 8 mm

- Tool holders in 10×10, 12×12, 16×16 mm, right/left, with/without IC

- New Torx Plus clamping screw for quick handling

The system thus covers many typical applications on sliding headstock lathes – from parting off and grooving to demanding back-turning operations.

Conclusion: How you benefit from System 208

System 208 is more than just a further development of existing grooving systems. It is specially tailored to the conditions of sliding headstock turning technology and addresses the key challenges: limited space, high precision and process reliability. Gühring has created a new system that meets technical requirements and at the same time improves cost-effectiveness in manufacturing.

This might also interest you:

30% more tool life: With this parting off plate you achieve maximum performance in high-grade steel

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

Hardly any space? These tool holders are perfect for grooving on sliding headstock lathes

Discover our tool holders for sliding headstock lathes from system 222 with shortened head length, precision cooling and easy insert change – ideal for tight spaces and maximum process reliability when grooving.

New feature: Reliable parting off in stainless steel with System 222

The System 222 for grooving and parting off has been expanded: With two cutting edges and a length of 22 mm, the new indexable insert is ideally suited for parting off the most common bar diameters made from stainless steel materials with a width of 3 mm.