Table of contents

1. More stability and running smoothness: RF 100 Sharp extra short

2. Bridging of interference contours: RF 100 Sharp medium length

3. Flexible use: RF 100 Sharp DIN+

4. Standard version with corner radii: RF 100 Sharp ER

5. Baumaße-Vergleich: RF 100 Sharp im Überblick

6. FAQ zu Längenauswahl bei Fräsern

Discover how choosing the right length when milling with the RF 100 Sharp not only improves the quality of your work, but also relieves your budget. This is because in the world of construction and manufacturing, the right length selection means not only precision, but cost-effectiveness as well. Make it easy for yourself – choose the right length, the right tool and optimise your workflows for maximum efficiency.

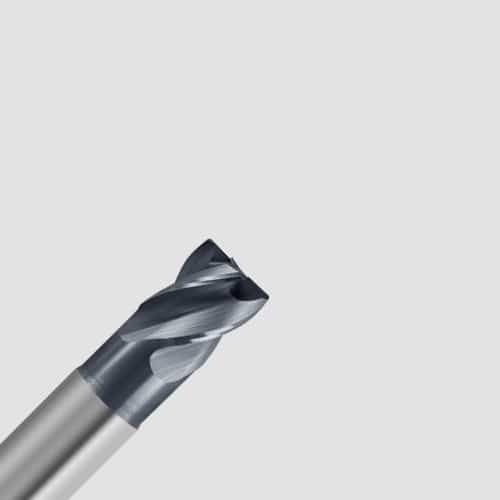

More stability and running smoothness: RF 100 Sharp extra short

- short dimension ensures high stability and running smoothness

- machining with up to 40 % higher feed rate

- cutting edge length of 1xD, 2xD the reach

- micro range dimensions from Ø 0.8 mm

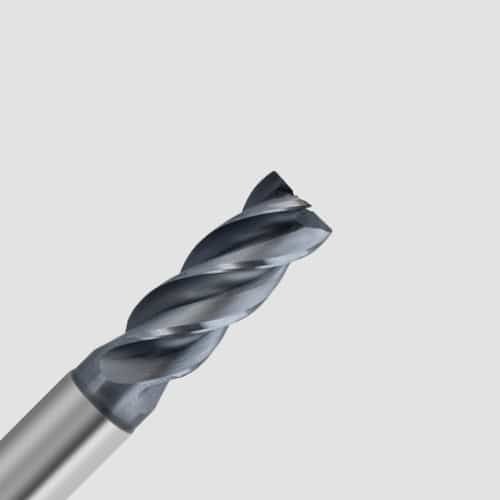

Bridging of interference contours: RF 100 Sharp medium length

- extended reach suitable for the bridging of interference contours at greater depths

- cutting edge makes up more than 50 % of the reach

- micro range dimensions from Ø 1.0 mm

Flexible use: RF 100 Sharp DIN+

- flexible use at different depths, requiring fewer milling cutters and making it possible to regrind more often

- based on “DIN 6527 long”, but +12 % more cutting length (with Ø 16.0 mm)

- dimensions from Ø 1.0 mm

Standard design with corner radii: RF 100 Sharp ER

- standard design according to “DIN 6527 long”

- dimensions from Ø 3.0 mm

- corner radii available from 0.2-4 mm

Dimension comparison: RF 100 Sharp overview

| Product | d1 mm |

d3 mm |

l1 mm |

l2 mm |

l3 mm |

Z |

| RF 100 Sharp ER | 16.0 | 15.5 | 92.0 | 32.0 | 43.0 | 4 |

| RF 100 Sharp DIN+ | 16.0 | 15.5 | 92.0 | 36.0 | 43.0 | 4 |

| RF 100 Sharp medium length | 16.0 | 15.5 | 123.0 | 38.0 | 74.0 | 4 |

| RF 100 Sharp extra short | 16.0 | 15.5 | 82.0 | 16.0 | 32.0 | 4 |

Technical advice and support are also available quickly and directly via our service hotline 00800 2607 2607

We can also be reached on WhatsApp: +49 172 658 53 53. Save the number!

You might also be interested in:

Efficiency without compromise: Solid carbide circular milling cutters for smooth slotting and grooving

Gühring is adding a powerful solid carbide circular milling cutter to its grooving tool range. The tool not only scores with perfect surface qualities and long tool lives, but also impresses with significantly smoother running compared to the competition. For maximum cost-effectiveness when milling slots and internal contours.

Experts in stainless steels: 3 tools for stainless steel machining

With the new high-performance tools for stainless steel machining, Gühring offers the optimal solution. Special coatings and adapted geometries guarantee the highest cutting values and extended service life. This means that the most demanding machining tasks can be mastered in a wide range of industries.

Six times higher metal removal rate: New micro-precision milling cutter for ISO-N materials

The RF 100 AL Micro offers an outstanding combination of precision, efficiency and process reliability, making it the first choice when machining aluminium, copper and brass. With its innovative properties this tool raises the bar for micro-machining.