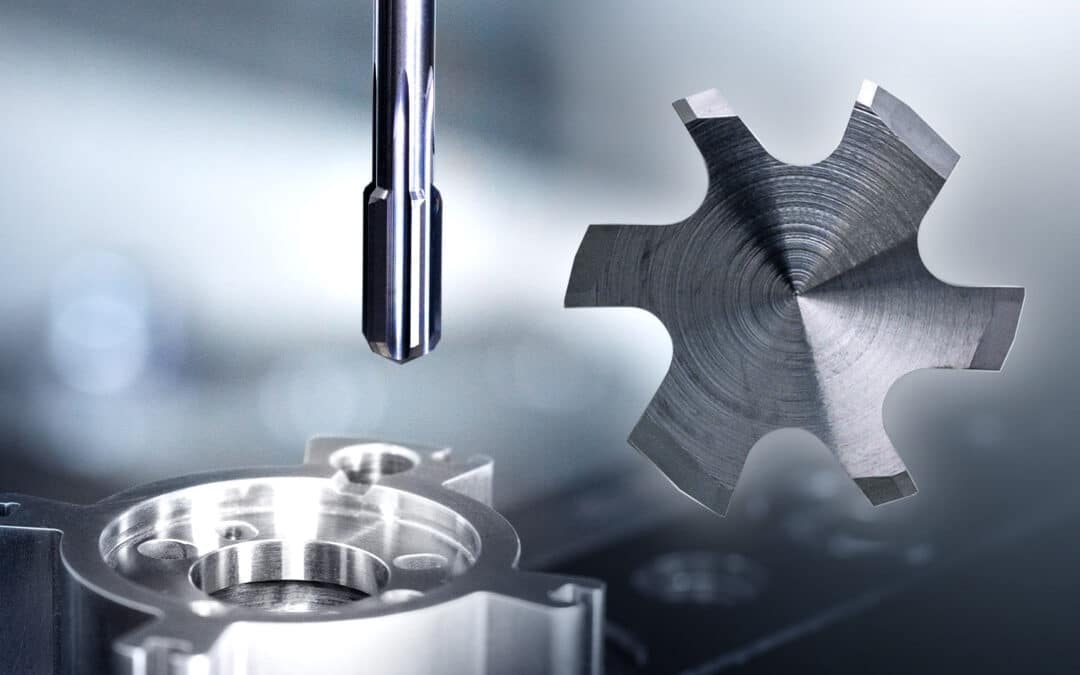

New market standard: The perfect fit for any diameter range

Gühring is expanding the diameter range of its high-performance reamer, the HR 500, by dimensional increments of +-0.05 mm. The result: With the new fixed-size reamers in 5µ increments, Gühring covers all tolerance ranges with a precision-fit.