Marcel Horn (GÜHRING, left) and Philipp Hüsch (Karl Georg) are delighted with the new modular fluteless tap.

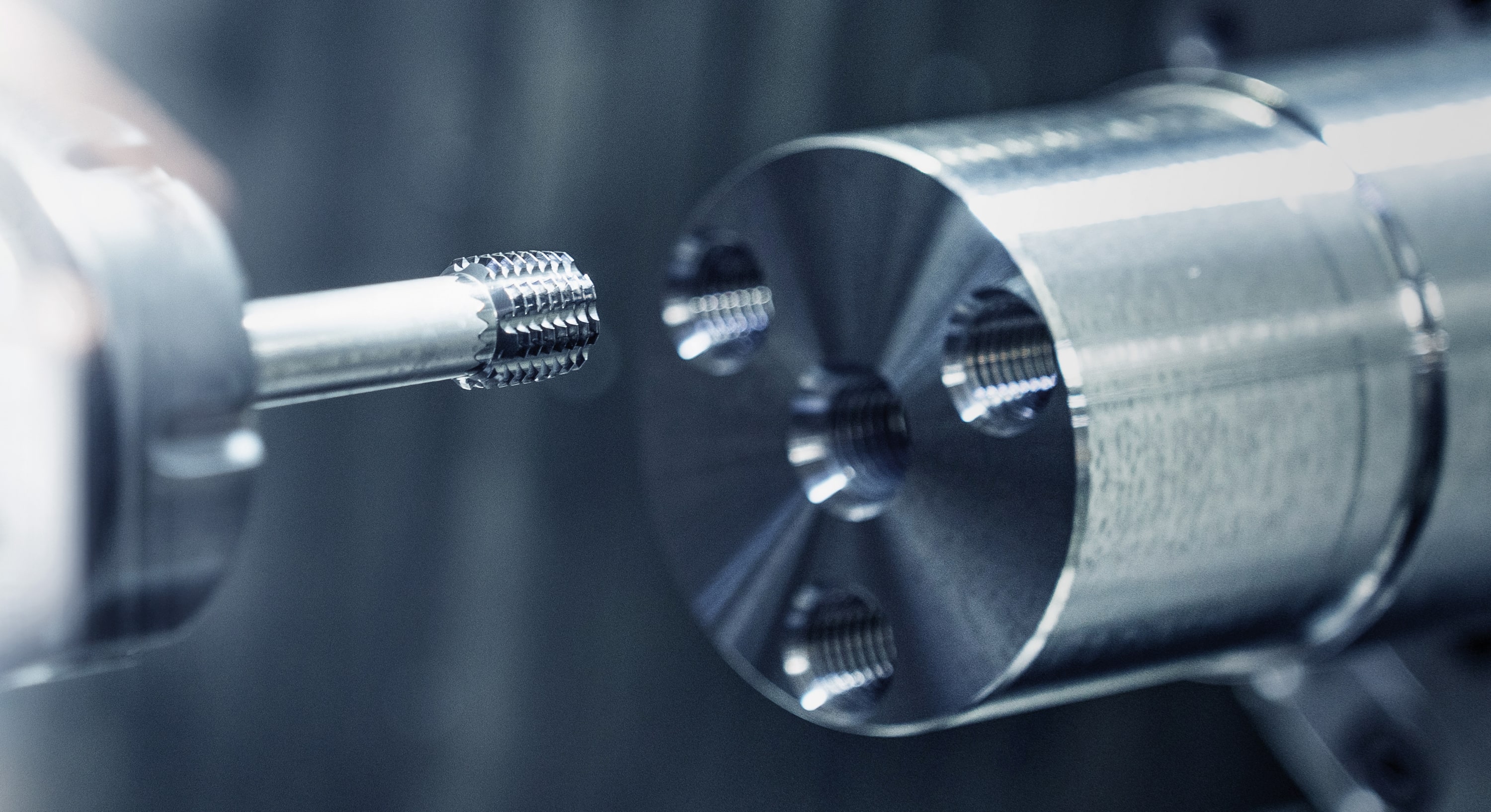

An innovation – the new modular fluteless tap from Gühring – has made it possible to solve deep-seated challenges in the production of blind hole threads at Karl Georg and to raise process reliability to a new level.

TABLE OF CONTENTS

Focus on precision and process reliability

Chip removal from deep blind holes

The solution: The modular fluteless tap

Safe and fast: Fluteless tapping instead of tapping

A strong team for big tasks

Summary: Your benefits with the modular fluteless tap

Focus on precision and process reliability

In the port, where containers weighing tonnes are moved by gigantic cranes, everything depends on precision: gears mesh, shafts drive and every single component has to withstand the highest loads. But as impressive as these machines look, precision on a small scale is just as crucial.

“Our machines process workpieces ranging in size from 20 millimeters to 1400 millimeters – theres ‘a lot of expertise behind them, ” explains Philipp Hüsch, who is responsible for tool purchasing and processes at Karl Georg. “However, we have faced considerable challenges in the past, especially when it comes to threads.”

Karl Georg: specialist in crane components

Karl Georg, a traditional family business based in the heart of Germany, is a specialist in crane components that is in demand worldwide. With 146 employees, the company manufactures, among other things, wheels that are used in harbour cranes or heavy-duty logistics systems. This year, the company is celebrating its centenary – and can look back on impressive growth and technological advances.

Chip removal from deep blind holes

The production of blind hole threads in drive and idler shafts, which are later shrunk into the crane running gears, is particularly challenging. Here, thread depths of up to 70 millimeters have to be produced with thread cutters – unusually deep for an M16 thread. This depth regularly led to problems with chip removal.

“In the past, we often lost tool life because chips got stuck in the blind hole. Often the tool even broke off and could no longer be removed from the hole,” recalls Hüsch. “The entire component became scrap.” Such incidents are particularly annoying when they occur in an automated machining process: the entire process comes to a standstill, machines have to be stopped and valuable time is lost. “I have to be able to rely on the process,” emphasises Hüsch.

The solution: the modular fluteless tap

Until now, Karl Georg had to rely on special tools for such deep threads, but here Gühring field service consultant Marcel Horn had a different idea: the new modular fluteless tap. “The length here is perfect and we don’t have to work with any extensions or special concepts, ”explains Marcel Horn. Another advantage of the Gühring system is the connection between the HSS tool shank and the carbide thread head. The AlCrN coating of the thread head ensures high wear resistance, while the repeated use of the shank drastically reduces the costs per component. In addition to the practical benefits, the process change also offers improved quality: fluteless tapping produces particularly strong threads that can easily withstand the high loads in crane system operation. For a company like Karl Georg, which depends on reliability and precision, this is a decisive competitive advantage.

Safe and fast: fluteless forming instead of tapping

“This not only makes the entire process safer, but also faster.”

“That was a real game changer,” reports Philipp Hüsch. In contrast to taps and milling cutters, where the chips have to be removed from the blind hole, no chips are produced during fluteless tapping. “This not only makes the entire process safer, but also faster,” says Hüsch. The modularity of the mould is particularly impressive. “The shank is retained and only the tool head is replaced when it wears out. This saves costs and simplifies replacement considerably,” explains Hüsch.

For Karl Georg, this means no more customised solutions, no complex adjustments, but an efficient and trouble-free process. “With this tool, we have not only tripled tool life from 20 to 60 minutes, but also significantly reduced machining times, as redrilling for chip removal is no longer necessary.”

3 x longer tool life and one less working step

| Tool | Modular fluteless tap, Ø = M16x2 Art no. 4871 Head Art no. 4873 Shank |

| Material | 42CrMo4 (1.7225) |

| Feed | f = 1,200 mm/rev |

| Cutting speed | Vc = 30 m/min |

| Speed | n = 600 rpm |

The synchronised chuck developed by Gühring also contributes to process stability. It equalises axial and radial loads and thus extends the tool life. “This was a real added value for us, as the tools last even longer and the quality of the threads remains at a consistently high level,” emphasises Hüsch.

A strong team for big tasks

The collaboration between Karl Georg and Gühring has existed for five years and has steadily deepened since then. “Our tool management used to be a bit of a mess,” recalls Philipp Hüsch. “But after we rigorously switched all our threading tools to Gühring, we’ve only had positive experiences.”

With the modular fluteless tap, Gühring has developed a solution that fulfils the special requirements of Karl Georg and guarantees maximum process reliability. For Hüsch and his team, this means less downtime, fewer scrap and greater efficiency – a success story that shows how small changes can lead to big changes.

Using teamwork to solve problems (from left to right): Philipp Hüsch, Rudolf Wall (both Karl Georg) and Marcel Horn (Gühring).

Summary: Your benefits with the modular fluteless tap

Modular fluteless tap

Modular system for maximum flexibility and efficiency

The modular system, consisting of a steel shank with an interchangeable carbide thread head, enables maximum flexibility and shorter reaction times. The tool can also be used in less than ideal conditions, e.g. on older machines. The carbide thread head reduces cycle times while significantly increasing tool life.

Your benefits with the modular fluteless tap:

- high cost-effectiveness thanks to multiple use of the tool shank after the thread head has worn (up to 8 times)

- cost reduction due to modular replacement system

- also suitable for less than ideal conditions

- reduction in torque due to special polygon shape and coating

Das könnte Sie auch interessieren:

Strong in steel & reliable in process High-performance taps for the energy industry

Large components, special thread solutions and tight tolerances – the challenges in the energy industry place the highest demands on machining. With the Energy tap, Gühring is launching an industry specialist that produces demanding threads.

Experts in stainless steels: 3 tools for stainless steel machining

With the new high-performance tools for stainless steel machining, Gühring offers the optimal solution. Special coatings and adapted geometries guarantee the highest cutting values and extended service life. This means that the most demanding machining tasks can be mastered in a wide range of industries.

Maximum flexibility and economic efficiency: Modular threading tools

Gühring combines the advantages of carbide and high speed steel in one tool by screwing a carbide head onto an HSS shank. The result is a new modular system of fluteless taps – for more flexibility in fluteless tapping.