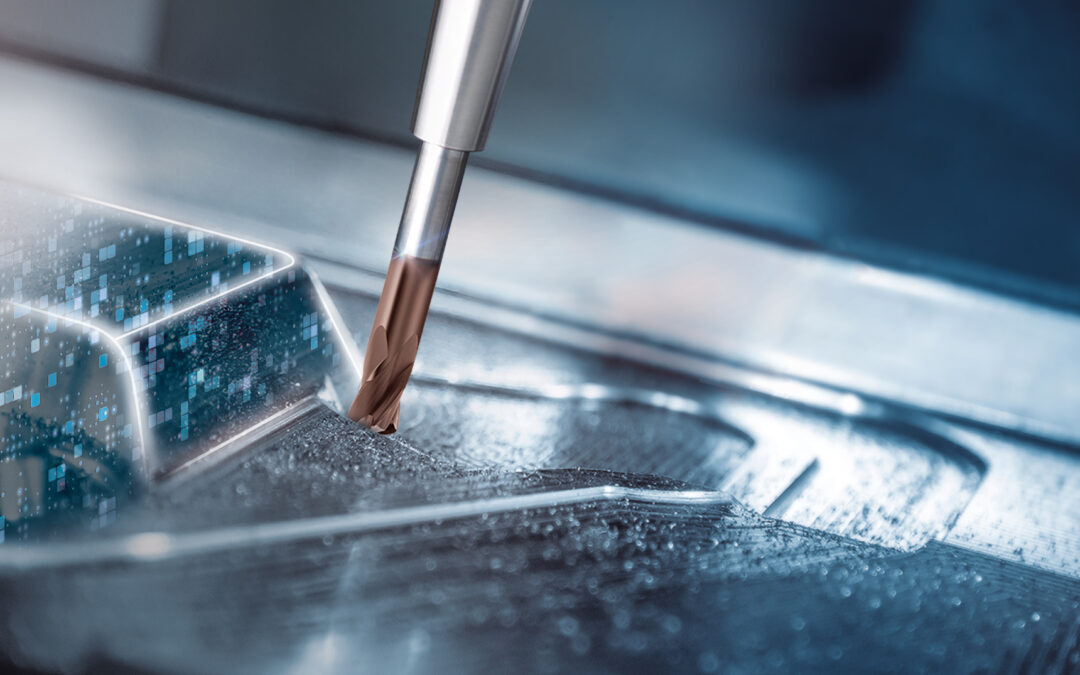

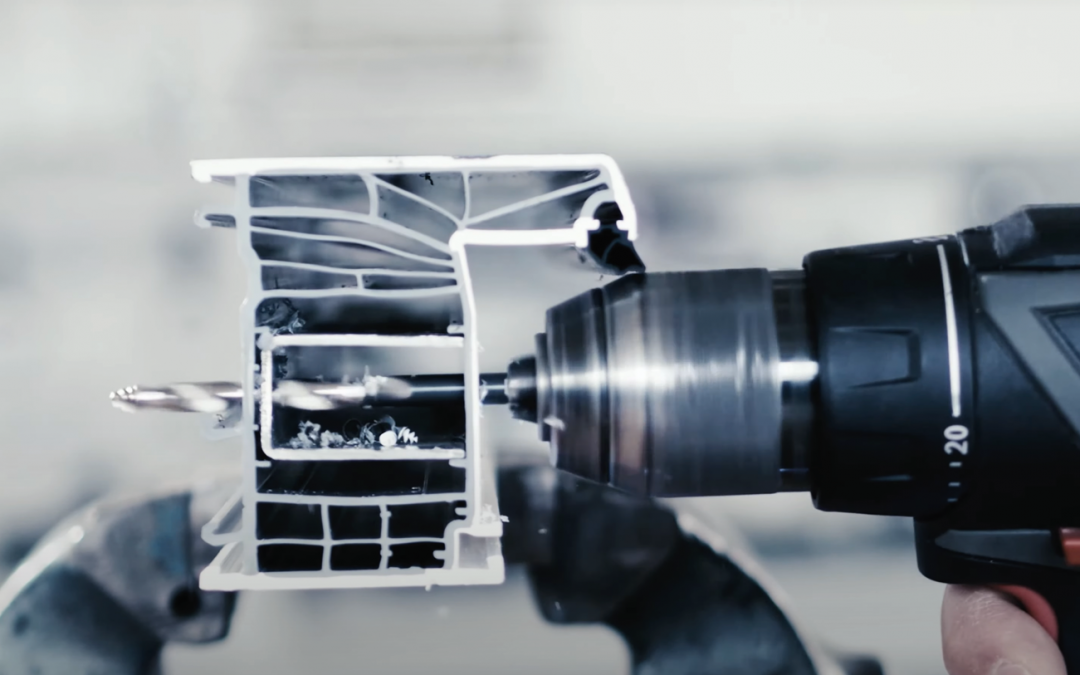

6 reasons why your production needs a tool management system

Searching for tools takes an incredible amount of time. All tools have their place in our tool management cabinets. Tidy, locked, with controlled dispensing. In this article, you will find out how to revolutionise your production and save costs.