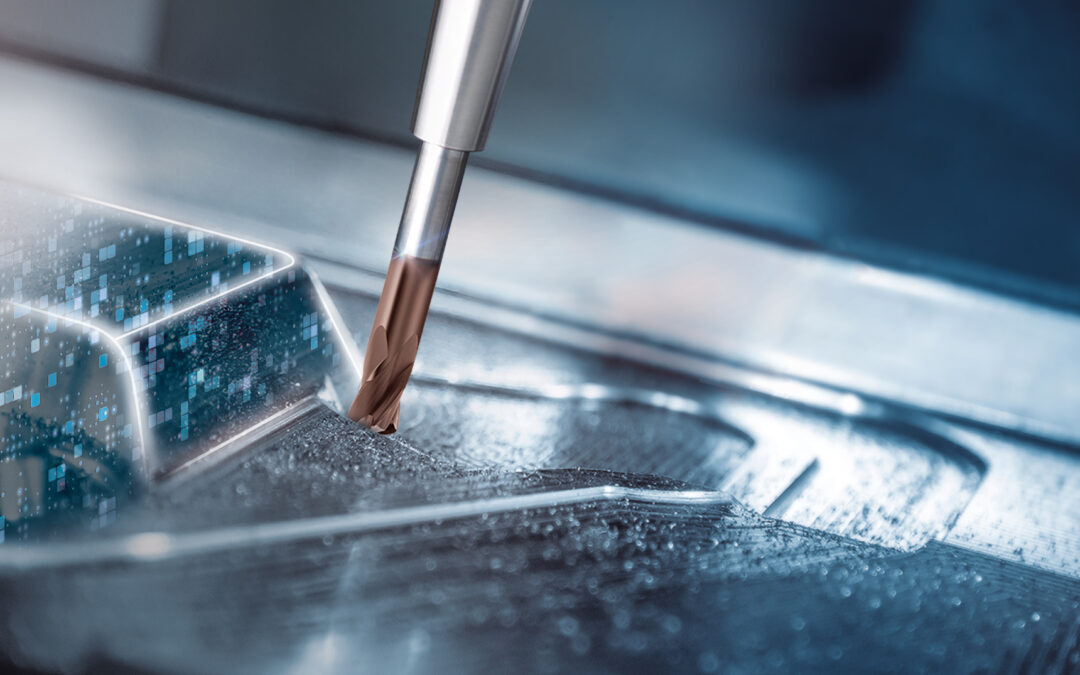

Save one working step when drilling on inclined surfaces

The new RT 100 FB flat drill is our specialist for challenging spot drilling situations and eliminates the need to face with a milling cutter. This saves one process step and one tool when drilling on inclined or curved surfaces.