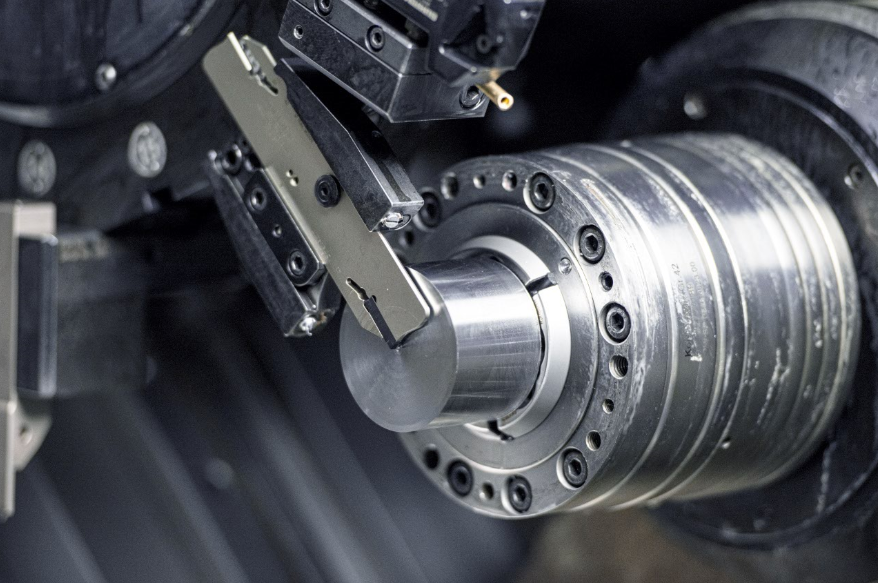

Tool life up, costs down: three tools for higher parameters

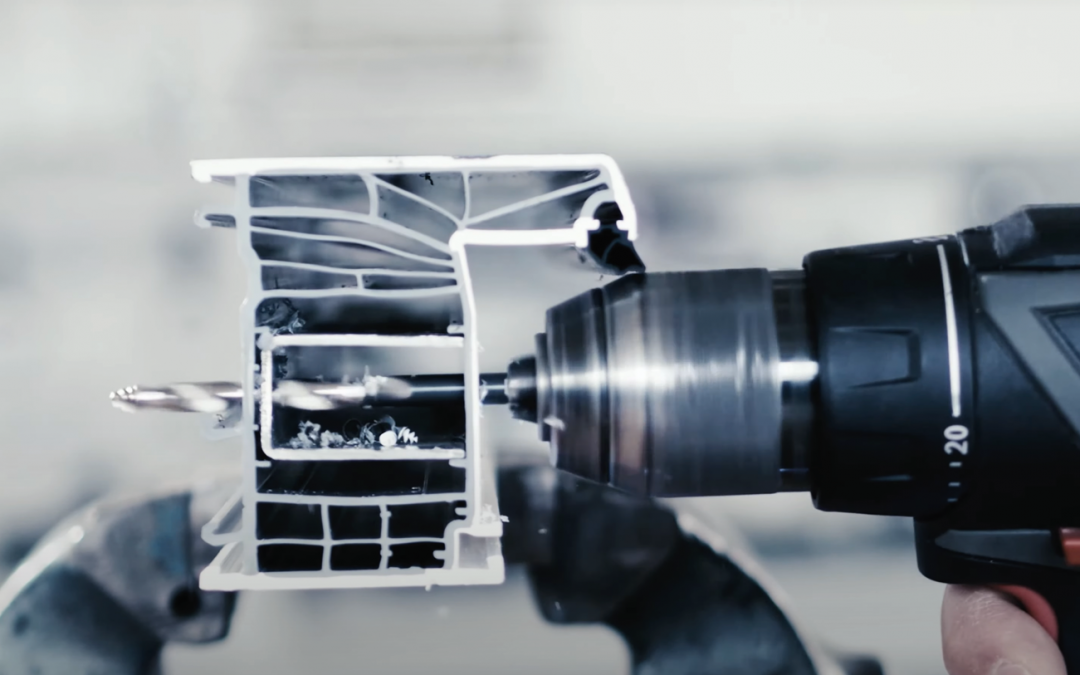

Enjoy longer tool lives and save money at the same time: Hennecke from Sankt Augustin is managing to do that together with Gühring. Three SC highlight products show why the machine and system manufacturer relies almost exclusively on Gühring for milling.