GTMS from the beginning: Philipp-Matthäus-Hahn-School digitizes tool management with Gühring

With software and dispensing cabinets from Gühring, the Philipp-Matthäus-Hahn School is digitizing its tool management. This not only takes the school a step towards digitalization, but also fosters the next generation of skilled workers.

Efficiency without compromise: Solid carbide circular milling cutters for smooth slotting and grooving

Gühring is adding a powerful solid carbide circular milling cutter to its grooving tool range. The tool not only scores with perfect surface qualities and long tool lives, but also impresses with significantly smoother running compared to the competition. For maximum cost-effectiveness when milling slots and internal contours.

Strong in steel & reliable in process High-performance taps for the energy industry

Large components, special thread solutions and tight tolerances – the challenges in the energy industry place the highest demands on machining. With the Energy tap, Gühring is launching an industry specialist that produces demanding threads.

Gühring extends its thanks: Festive tribute to long-serving employees and new retirees

At a festive ceremony in the Stadthalle Balingen, the management of Gühring recently honored 41 long-serving employees and 48 new retirees.

System 208: Precision and process reliability for sliding head turning technology

With the new System 208, Gühring is launching a grooving system that has been specially developed for sliding headstock lathes. It specifically meet the requirements for machining complex micro-turned parts.

Carbon masks save sports stars: customised high-tech orthoses with precision from Gühring

Especially for a team’s top performers, an injury due to a broken nose or cheekbone is catastrophic. This is precisely when Malzkorn’s product comes into play: carbon fiber-reinforced face masks for elite athletes.

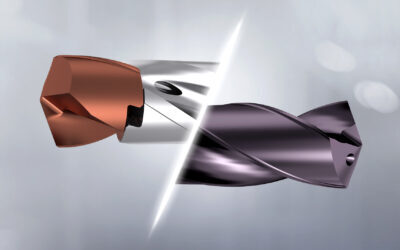

150 % longer tool life: the interchangeable head drilling system for maximum cost-effectiveness

Modular drilling systems enable quick head changes within the machine – but if process reliability is lacking, the time savings can quickly become negligible. The BT 800 demonstrates that simple handling and performance don’t have to be mutually exclusive.

Conserving resources for the future: 5 reasons for carbide recycling

Save resources and benefit from carbide recycling with Gühring! Exchange worn tools for money and reduce your carbon footprint. Simple, sustainable and efficient.

The Gühring Tool Circle: Earn money with carbide recycling

Gühring purchases worn tools and other carbide scrap, feeds it into the recycling process and recovers valuable secondary raw materials. Thanks to the bonus model, customers benefit from the Gühring Tool Circle in several ways.

Universal and unbeatable: double service life with the HR 500

Best hole qualities, tight tolerances, maximum precision: these are the key factors in the manufacture of mould inserts made of hardened steel. This customer relies on high-performance reamers from Gühring’s HR 500 range.

Go Team Gühring: Impressions from the Albstadt Bike Marathon 2025

Last Saturday, Gühring took part in the Albstadt Bike Marathon for the very first time with its own team – and all 52 motivated riders successfully crossed the finish line!

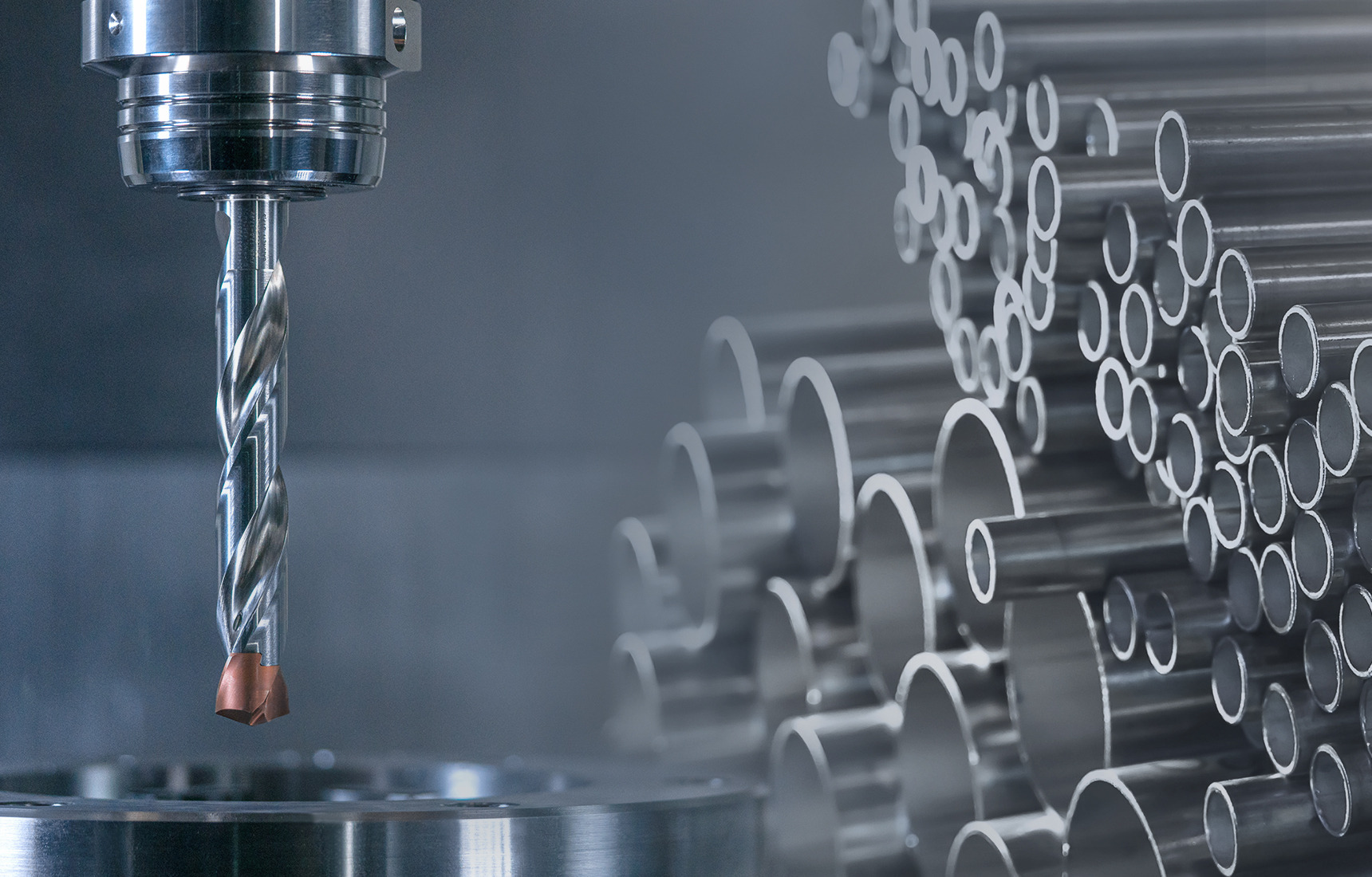

BT 800: The better choice for modern drilling processes

With the BT 800, Gühring is launching a high-performance replaceable head drilling system with bayonet lock, which is particularly impressive in medium to large diameters from Ø 14 mm due to its cost-effectiveness, flexibility and tool life.

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.

Threads for giants: Crane manufacturer relies on modular fluteless tap for blind holes

An innovation – the new modular fluteless tap from Gühring – has made it possible to solve deep-seated challenges in the production of blind hole threads at Karl Georg and to raise process reliability to a new level.