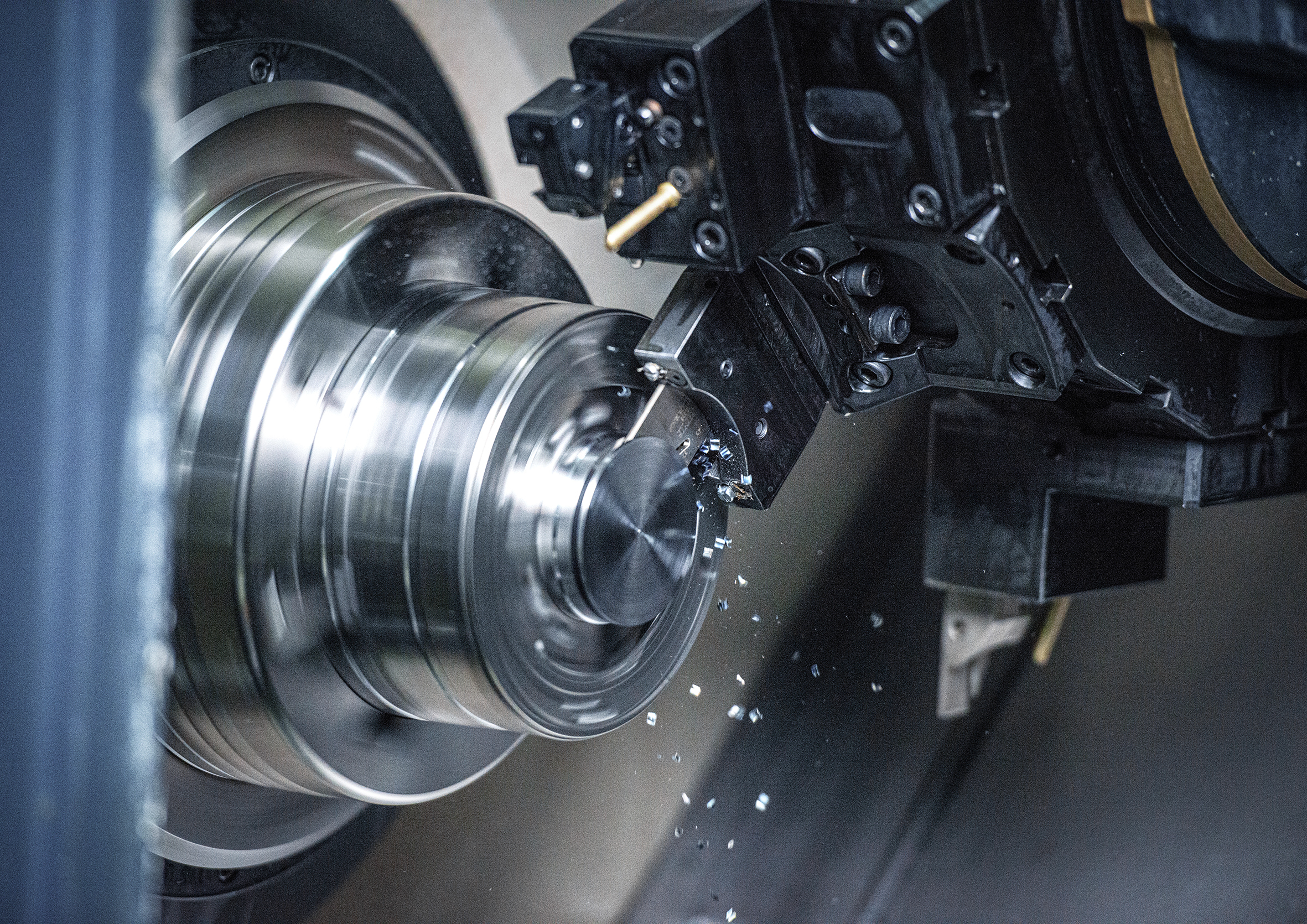

Efficiency without compromise: Solid carbide circular milling cutters for smooth slotting and grooving

Gühring is adding a powerful solid carbide circular milling cutter to its grooving tool range. The tool not only scores with perfect surface qualities and long tool lives, but also impresses with significantly smoother running compared to the competition. For maximum cost-effectiveness when milling slots and internal contours.

Strong in steel & reliable in process High-performance taps for the energy industry

Large components, special thread solutions and tight tolerances – the challenges in the energy industry place the highest demands on machining. With the Energy tap, Gühring is launching an industry specialist that produces demanding threads.

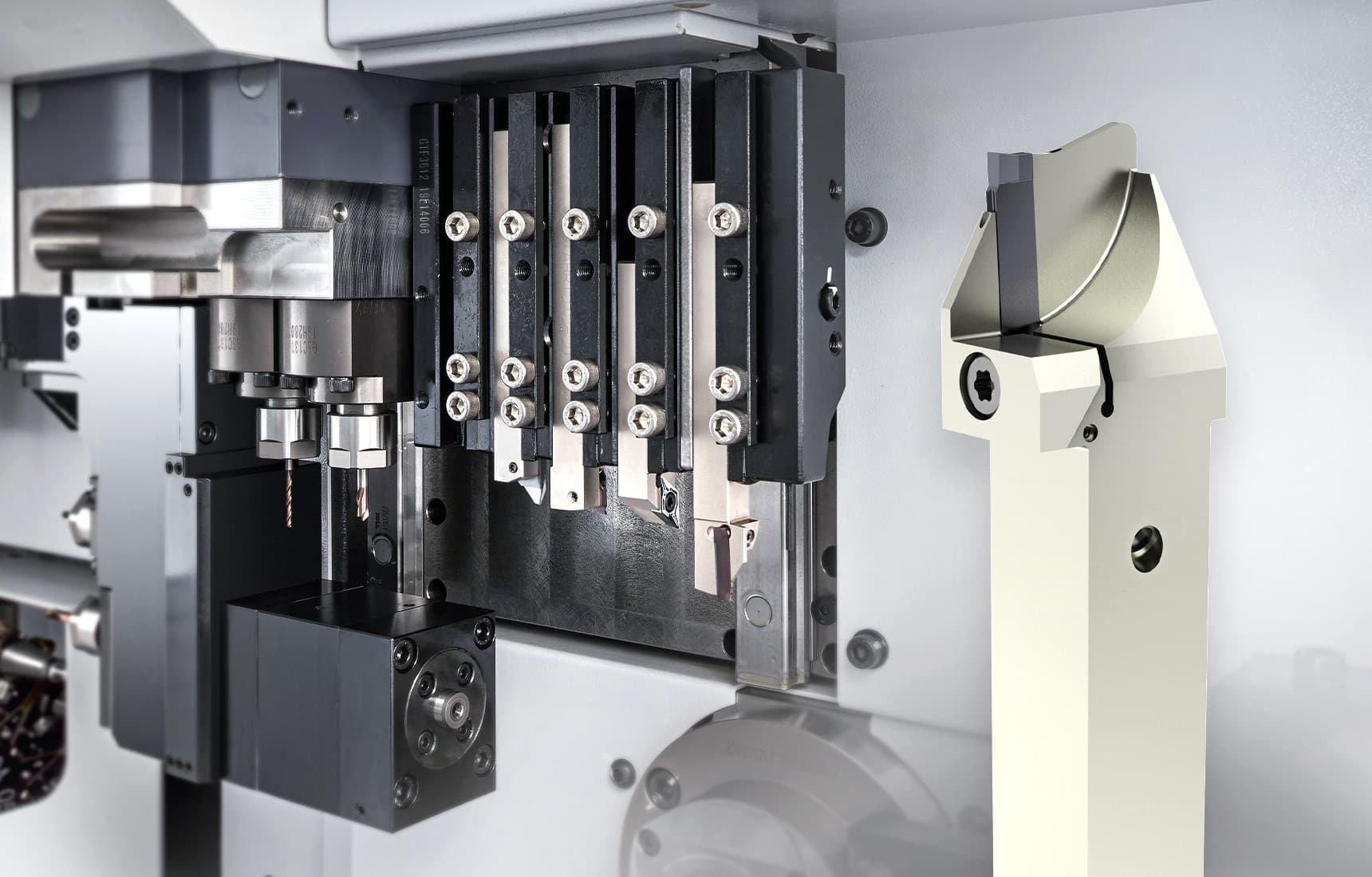

System 208: Precision and process reliability for sliding head turning technology

With the new System 208, Gühring is launching a grooving system that has been specially developed for sliding headstock lathes. It specifically meet the requirements for machining complex micro-turned parts.

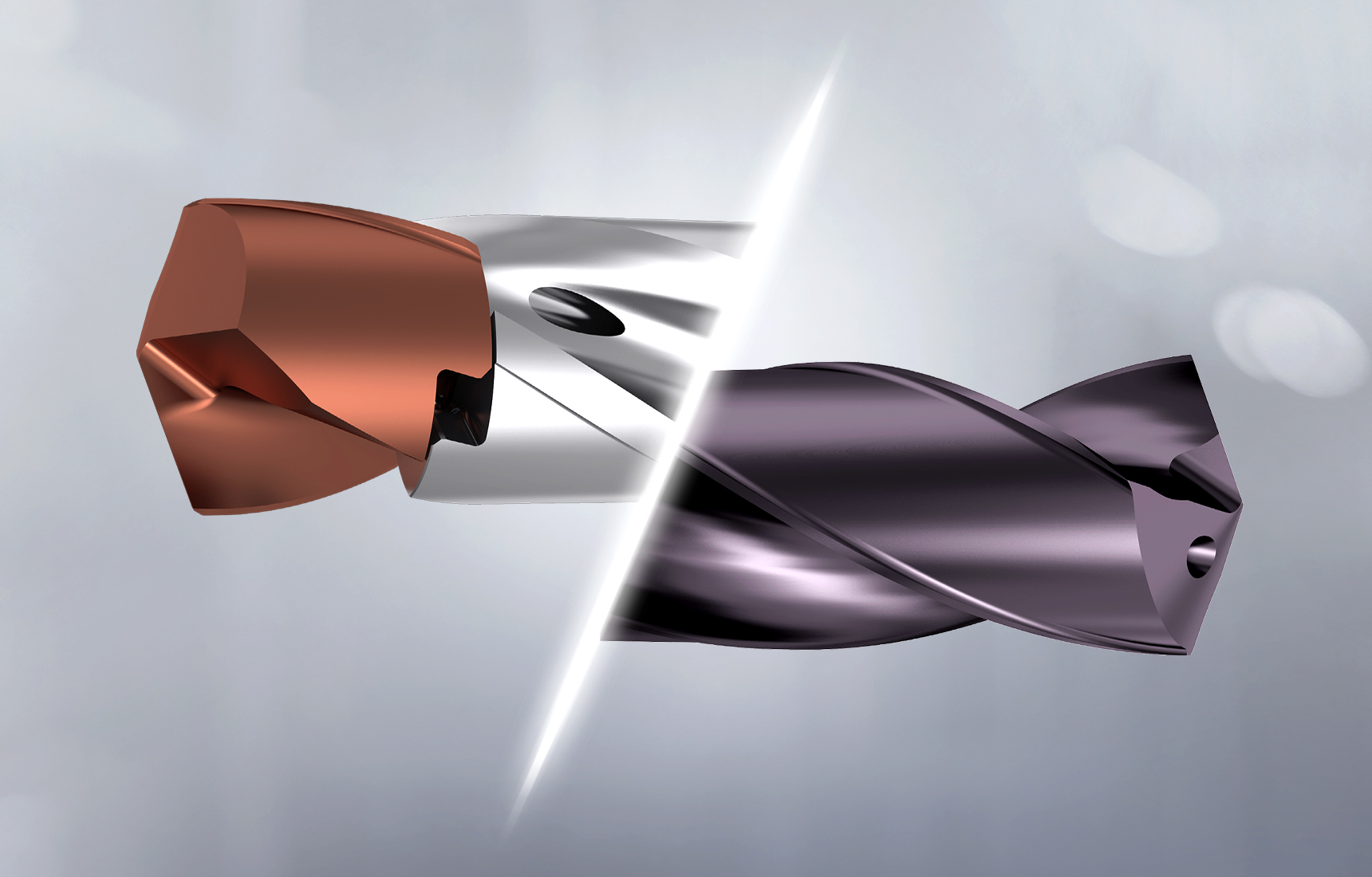

Maximum economic efficiency: Modular drill reduces set-up times and scrap for the customer

Tool life up, machining times down: With the BT 800 interchangeable head drilling system, the company Kurt Metallverarbeitung has found a modular solution that not only impresses with simpler handling, but also with outstanding performance.

Modular drills: Their advantages and how you can benefit from them

Modular drilling systems such as the BT 800 from Gühring offer full performance at lower costs. Thanks to interchangeable drill heads, you save time, storage space and money – ideal for flexible applications with the highest demands on cost-effectiveness.

Threads for giants: Crane manufacturer relies on modular fluteless tap for blind holes

An innovation – the new modular fluteless tap from Gühring – has made it possible to solve deep-seated challenges in the production of blind hole threads at Karl Georg and to raise process reliability to a new level.

30% more tool life: With this parting off plate you achieve maximum performance in high-grade steel

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

Hardly any space? These tool holders are perfect for grooving on sliding headstock lathes

Discover our tool holders for sliding headstock lathes from system 222 with shortened head length, precision cooling and easy insert change – ideal for tight spaces and maximum process reliability when grooving.

Experts in stainless steels: 3 tools for stainless steel machining

With the new high-performance tools for stainless steel machining, Gühring offers the optimal solution. Special coatings and adapted geometries guarantee the highest cutting values and extended service life. This means that the most demanding machining tasks can be mastered in a wide range of industries.

Six times higher metal removal rate: New micro-precision milling cutter for ISO-N materials

The RF 100 AL Micro offers an outstanding combination of precision, efficiency and process reliability, making it the first choice when machining aluminium, copper and brass. With its innovative properties this tool raises the bar for micro-machining.

With three cutting edges, you can create a 180° hole base faster than ever before

While competitors rely on two cutting edges in their 180° flat drills, Gühring is launching a three-fluted tool. And to great success: The FB 200 U excels with up to 50% higher cutting values, process reliability and better hole quality.

Finger on the pulse: Pocket milling in grade 5 titanium

A customer uses grade 5 titanium to make the case for pacemaker batteries, but machining the material is challenging. Gühring has the solution: The G-Mold 65 HF solid carbide end mill enabled it to extend the tool life 73 times over.

New market standard: The perfect fit for any diameter range

Gühring is expanding the diameter range of its high-performance reamer, the HR 500, by dimensional increments of +-0.05 mm. The result: With the new fixed-size reamers in 5µ increments, Gühring covers all tolerance ranges with a precision-fit.

Diamond nozzle: 50 kg Carbon – limitless printing

CR-3D is a leading complete supplier in the field of additive manufacturing and develops and produces all necessary components for 3D printing in industrial environments. Gühring supplies the heart of this type of machine: the diamond printer nozzle.

Gühring milling cutter in the mix: Trochoidal milling in high-alloyed stainless steel

When milling wing supports made of austenitic chromenickel steel, milling cutters at ystral gmbh fail after just one component. A solid carbide milling cutter from Gühring ensures the necessary process reliability.