30% more tool life: With this parting off plate you achieve maximum performance in high-grade steel

30% more tool life when parting off: The new 2 mm parting off plate from Gühring’s System 222 impresses with excellent chip control, high process reliability and a perfect surface finish on ISO-M materials such as high-grade steel.

Hardly any space? These tool holders are perfect for grooving on sliding headstock lathes

Discover our tool holders for sliding headstock lathes from system 222 with shortened head length, precision cooling and easy insert change – ideal for tight spaces and maximum process reliability when grooving.

Tool management in flux: Keeping track with digital tech

Getsch+Hiller optimiert mit der Gühring Tool Management Software (GTMS) seine Werkzeugverwaltung. Dank digitaler Ausgabeschränke und modularer Software spart das Unternehmen Zeit, reduziert Kosten und bleibt flexibel – perfekt angepasst an das schnelle Wachstum der Medizintechnik.

Detailed data on your tools: The GTMS tool data module

Increase your efficiency with the GTMS tool data module. Avoid sources of error, optimise set-up times and gain full transparency over tool requirements and component costs. Experience precise tool data management for maximum control.

Breakthrough in highly heat-resistant steel: Impressive tool life with the RT 100 InoxPro

A highly heat-resistant steel was pushing the universal drills at Recker Technik to their limits. But with the RT 100 InoxPro stainless steel specialist from Gühring, the company found the solution – and is now achieving twice the tool lives with the same precision.

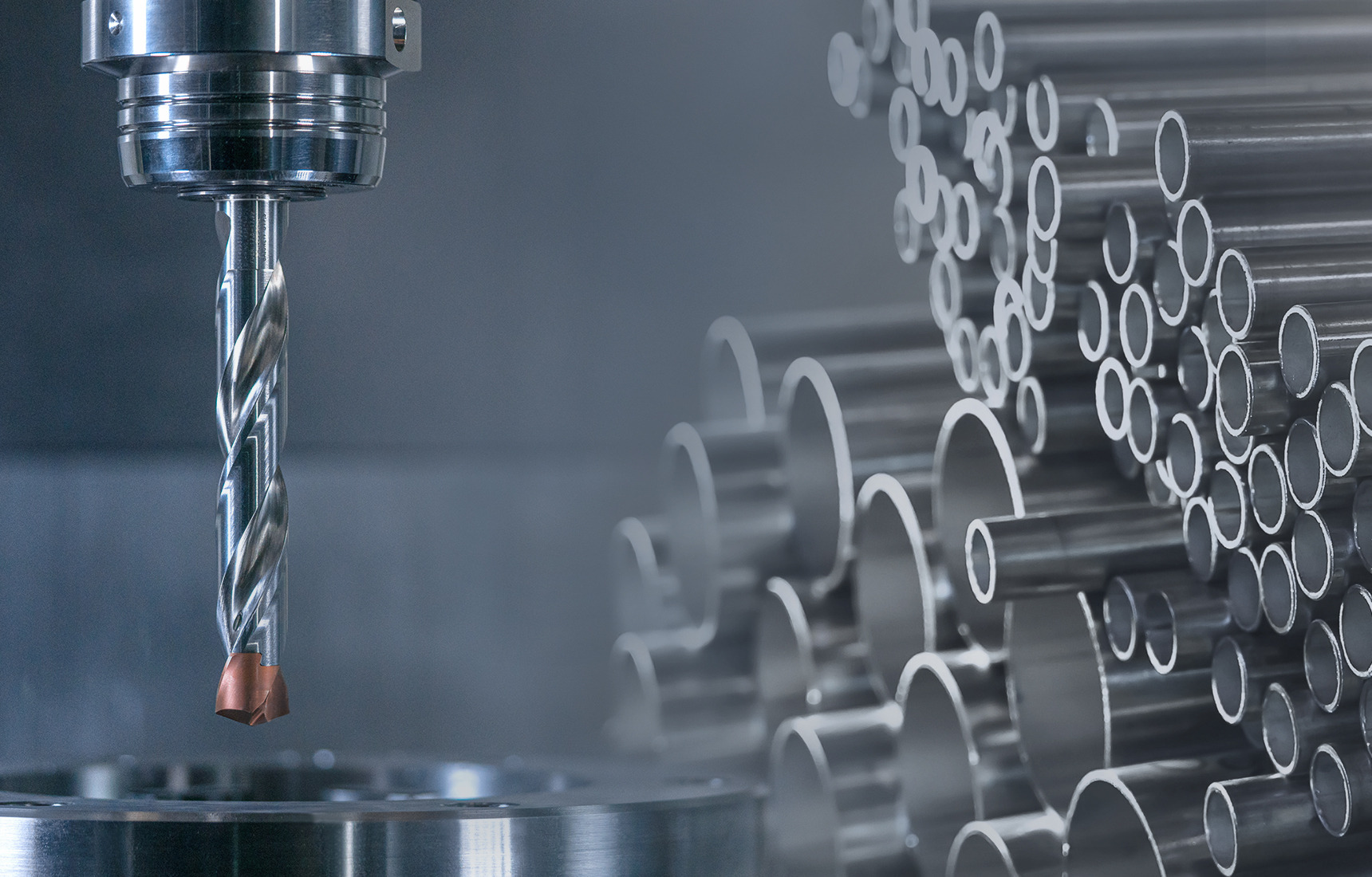

Experts in stainless steels: 3 tools for stainless steel machining

With the new high-performance tools for stainless steel machining, Gühring offers the optimal solution. Special coatings and adapted geometries guarantee the highest cutting values and extended service life. This means that the most demanding machining tasks can be mastered in a wide range of industries.

Six times higher metal removal rate: New micro-precision milling cutter for ISO-N materials

The RF 100 AL Micro offers an outstanding combination of precision, efficiency and process reliability, making it the first choice when machining aluminium, copper and brass. With its innovative properties this tool raises the bar for micro-machining.

With three cutting edges, you can create a 180° hole base faster than ever before

While competitors rely on two cutting edges in their 180° flat drills, Gühring is launching a three-fluted tool. And to great success: The FB 200 U excels with up to 50% higher cutting values, process reliability and better hole quality.

Finger on the pulse: Pocket milling in grade 5 titanium

A customer uses grade 5 titanium to make the case for pacemaker batteries, but machining the material is challenging. Gühring has the solution: The G-Mold 65 HF solid carbide end mill enabled it to extend the tool life 73 times over.

New market standard: The perfect fit for any diameter range

Gühring is expanding the diameter range of its high-performance reamer, the HR 500, by dimensional increments of +-0.05 mm. The result: With the new fixed-size reamers in 5µ increments, Gühring covers all tolerance ranges with a precision-fit.

Diamond nozzle: 50 kg Carbon – limitless printing

CR-3D is a leading complete supplier in the field of additive manufacturing and develops and produces all necessary components for 3D printing in industrial environments. Gühring supplies the heart of this type of machine: the diamond printer nozzle.

Gühring milling cutter in the mix: Trochoidal milling in high-alloyed stainless steel

When milling wing supports made of austenitic chromenickel steel, milling cutters at ystral gmbh fail after just one component. A solid carbide milling cutter from Gühring ensures the necessary process reliability.

Digitalisation for experts: The GTMS Logistics Pro module

Optimise your production and reduce tool costs with the Logistics Pro module for Gühring Tool Management Software. The advanced module enables you to achieve efficient warehouse management, inventory support and also paperless communication.

4000 components, instead of 40: Unbeatable tool lives with the high-performance reamer

KIPP was facing a challenge: Their cast-steel products need to be equipped with through-holes with µ-level precision. With the HR 500 high-performance reamer, KIPP no longer has to worry about poor dimensional accuracy or short tool lives.

Everything under control? The GTMS basic module

Optimise your manufacturing process with Gühring Tool Management Software (GTMS). Effortlessly monitor tool usage and inventory levels, avoid the build-up of unused stock and increase efficiency. The GTMS basic module offers full control.