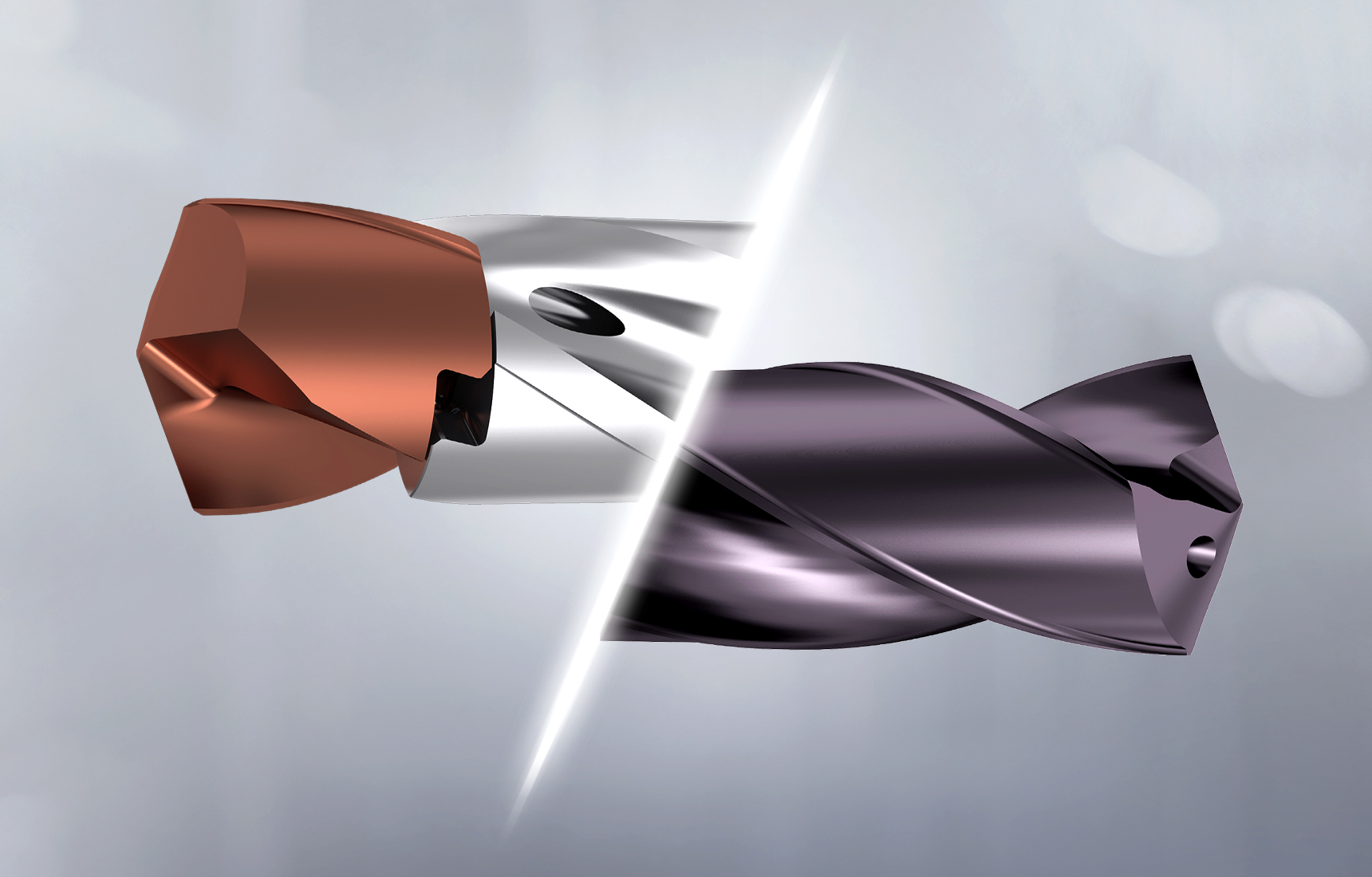

Save one working step when drilling on inclined surfaces

The new RT 100 FB flat drill is our specialist for challenging spot drilling situations and eliminates the need to face with a milling cutter. This saves one process step and one tool when drilling on inclined or curved surfaces.

Mill products yourself instead of buying-in expensive ones: How a Swabian company is cutting costs

A 130 % price increase for a blank presents economic problems for a customer. The solution? Do-it-yourself – with a brand-new machining strategy and tools from Gühring. The result: 50 % savings per component.

Top performance in titanium: Micro Diver impresses in the medical sector

Expertise and flexibility – both are essential when there are problems to solve. And this was also clear in the case of hg medical: Where conventional tools quickly reach their limits when it comes to wear, a Gühring micro-precision milling cutter slots for 1100 minutes in titanium.

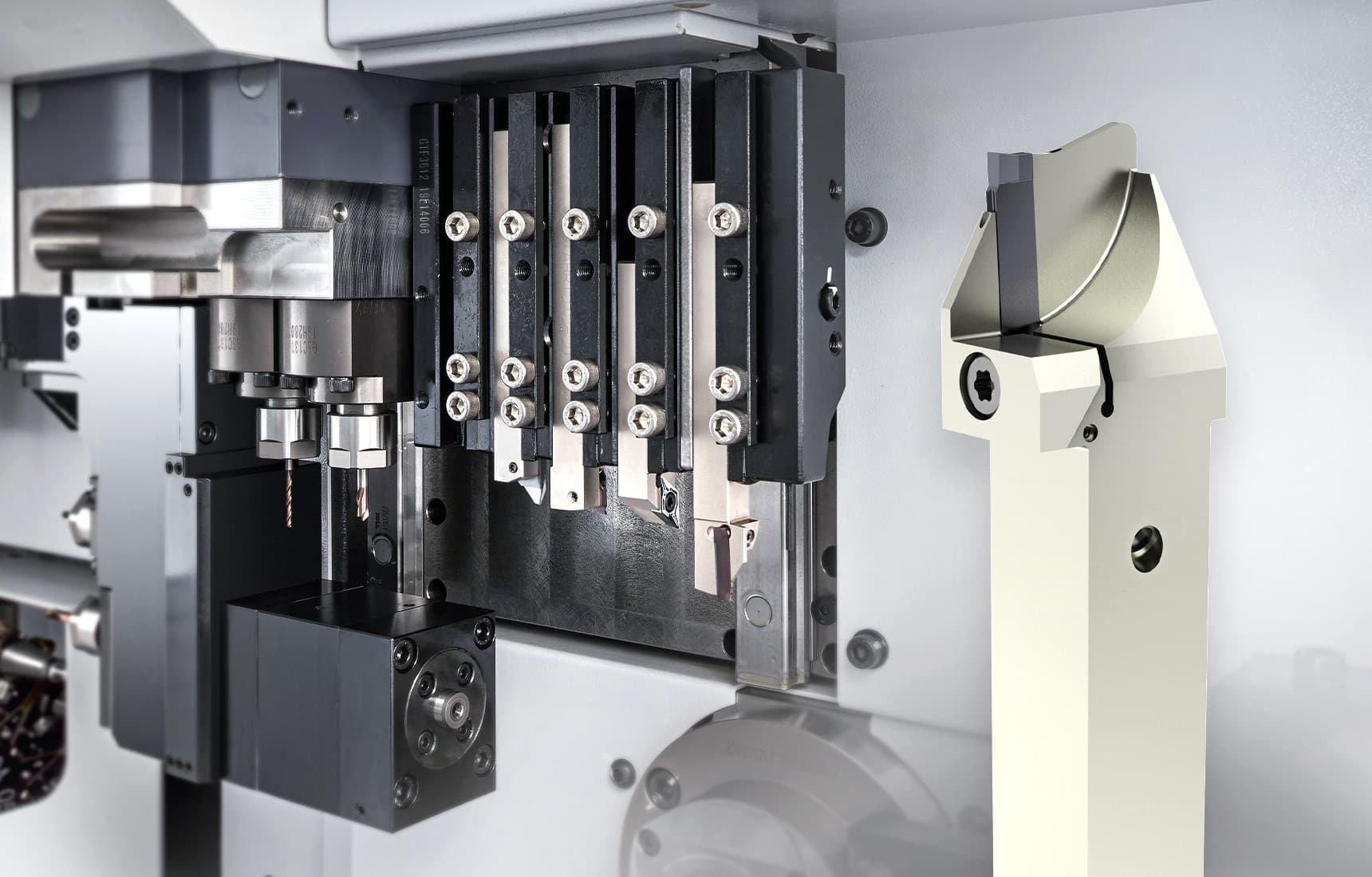

Tool shank and clamping chuck: Perfect concentricity thanks to a suitable clamping surface

The interaction between the tool shank and clamping chuck is important for perfect concentricity. In this article, we will introduce you to the different clamping surfaces HA, HB and HE and explain the consequences of choosing the wrong clamping surface.

“Licence to mill”: Bond car milled from solid material

Bringing together the three best products makes the perfect process. Gühring and Blaser have combined an MQL oil with a solid carbide corner radii milling cutter and a tool holder. And showcase the advantages that collaborative engineering can yield.

Four times more threads with hard milling

Tools for punching sheet metal have to withstand a lot. Hago Feinwerktechnik GmbH therefore uses materials of up to 66 HRC in its own toolmaking facilities. Here, two Gühring tools not only impress with low wear, but also with considerable cost savings.

Tool life up, costs down: three tools for higher parameters

Enjoy longer tool lives and save money at the same time: Hennecke from Sankt Augustin is managing to do that together with Gühring. Three SC highlight products show why the machine and system manufacturer relies almost exclusively on Gühring for milling.

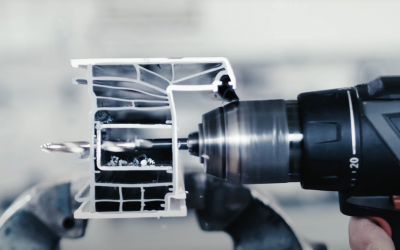

The new StepPower: circular holes by hand

Conventional handheld drills require a lot of force which can result in non-circular holes or annoying burrs at the hole exit. The new StepPower twist drill from Gühring masters these challenges. Its unique design ensures precise, circular holes.

Buying tools, protecting the environment: Packaging made from 100 % recycled plastic

Gühring is starting to gradually introduce sustainable packaging. This makes Gühring the first German tool manufacturer to use recycled material for its packaging – and saves the environment 234 tonnes of newly produced plastic every year.

RF 100 Sharp exceeds all expectations

With a result of 650 minutes of tool life and an excellent chip removal rate under unstable conditions, the solid carbide milling cutter RF 100 Sharp from Gühring exceeds the expectations of the metal machiner LB-Fertigungsservice GmbH from Altenstadt.

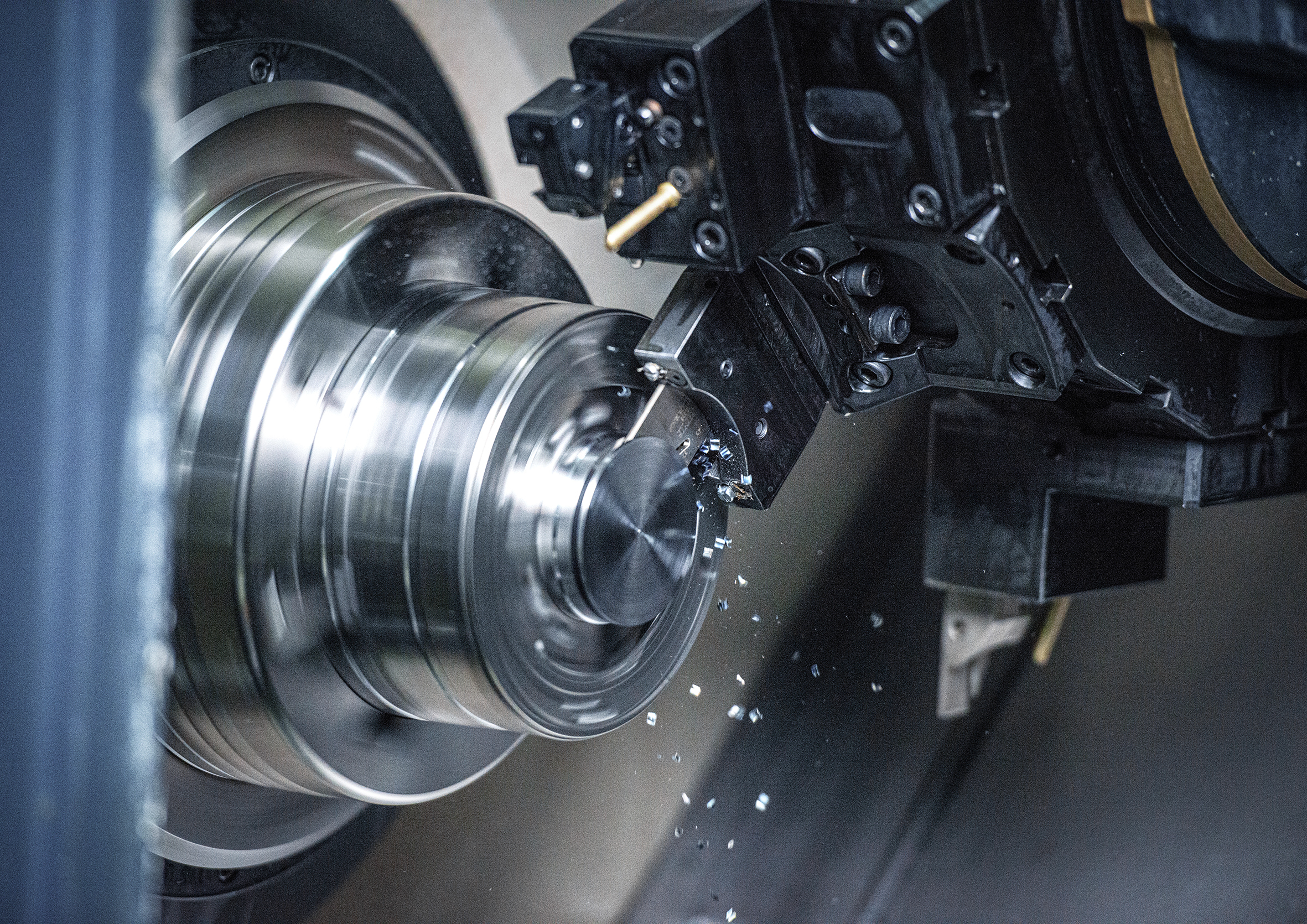

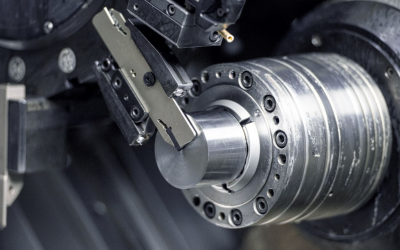

New feature: Reliable parting off in stainless steel with System 222

The System 222 for grooving and parting off has been expanded: With two cutting edges and a length of 22 mm, the new indexable insert is ideally suited for parting off the most common bar diameters made from stainless steel materials with a width of 3 mm.

Creating Threads: The most common mistakes and how to avoid them

The thread comes at the end of the production chain when you have already invested a lot of time and money in the component. We show you typical problems that occur when thread tapping, thread milling and fluteless tapping and how you can prevent them.

Controlled chip evacuation: 3D tool solves the seemingly impossible

The complicated evacuation of chips from an aluminium component causes problems for the automotive supplier Handtmann. Gühring delivers the solution with a PCD core drill tool made in a 3D printer. The result: no more chips in the connection holes.

VB 80 and VB 100: Cast machining at twice the speed

When you need to drill deep holes into powertrain components, these tools are the specialists: the VB 80 and the VB 100. Not only can the four-fluted cutters produce a wide diameter range, but they can also achieve drilling depths of up to 40xD.