Save one working step when drilling on inclined surfaces

The new RT 100 FB flat drill is our specialist for challenging spot drilling situations and eliminates the need to face with a milling cutter. This saves one process step and one tool when drilling on inclined or curved surfaces.

Integrate our online shop into your standardised purchasing processes

With a PunchOut interface, you can merge the Gühring online shop and your ERP system. You can securely access the shop from your ERP or transfer shopping carts to your system. Find out how you can benefit from cXML- and OCI-PunchOut here.

Gühring & osapiens: Supply chain and security of supply guaranteed!

Monitoring the entire supply chain, while still taking into account risks from outside production? Not an impossibility: With the help of Osapiens’ AI-supported software, Gühring is managing to achieve this all over the world – and in great detail at that.

Deep hole drilling in mould making

Deep hole drilling plays a significant role in the mould and die sector, especially in the production of injection moulding tools. High-quality cutting tools are indispensable for drilling holes with a high degree of precision and a good surface...

Mill products yourself instead of buying-in expensive ones: How a Swabian company is cutting costs

A 130 % price increase for a blank presents economic problems for a customer. The solution? Do-it-yourself – with a brand-new machining strategy and tools from Gühring. The result: 50 % savings per component.

Top performance in titanium: Micro Diver impresses in the medical sector

Expertise and flexibility – both are essential when there are problems to solve. And this was also clear in the case of hg medical: Where conventional tools quickly reach their limits when it comes to wear, a Gühring micro-precision milling cutter slots for 1100 minutes in titanium.

Ready for a new chapter

A total of 34 apprentices and students recently successfully completed their training at Gühring in Albstadt and Laiz. The examination certificates and diplomas were presented at a small celebration – including seven prizes and two commendations.

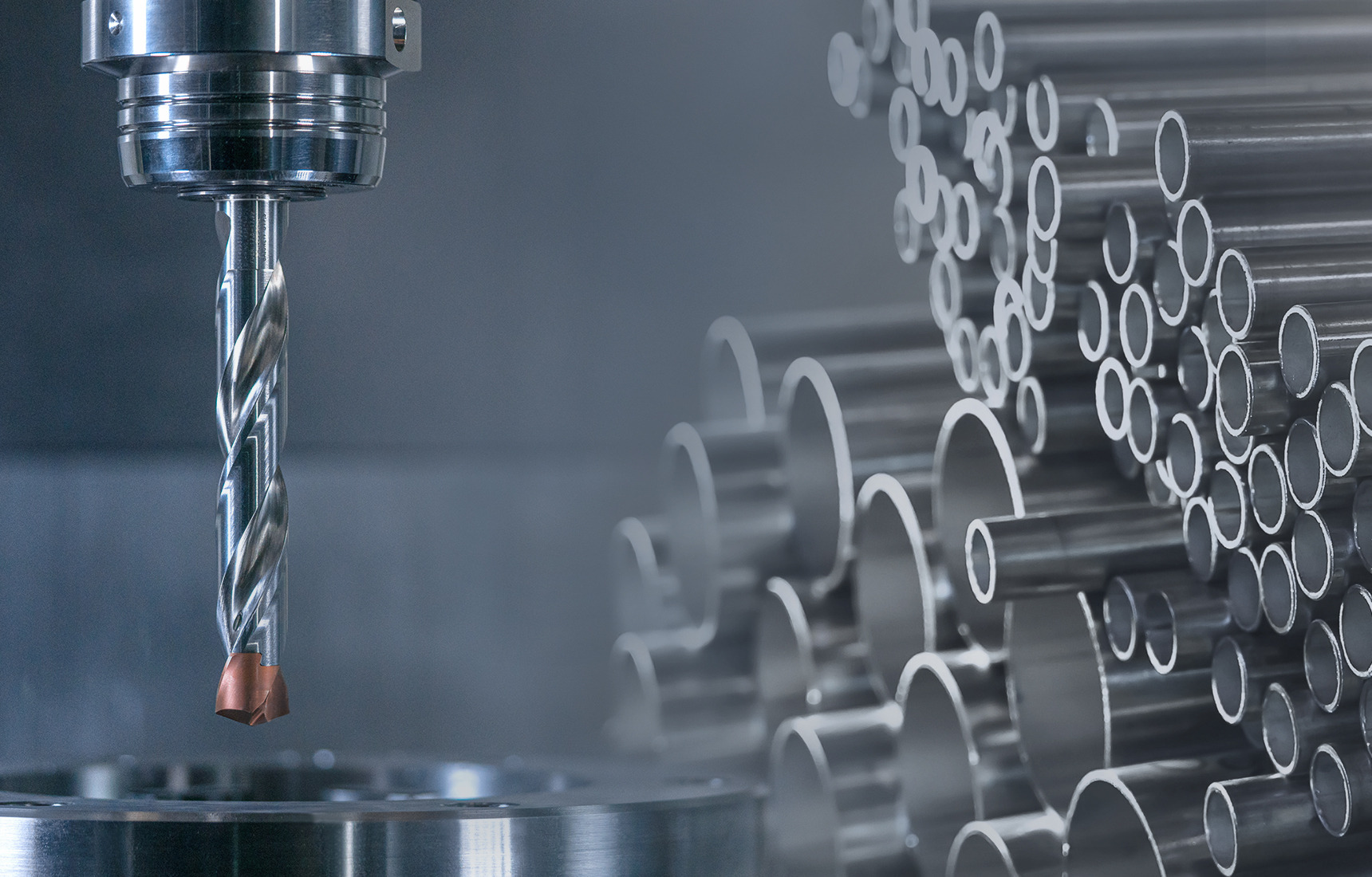

Tool shank and clamping chuck: Perfect concentricity thanks to a suitable clamping surface

The interaction between the tool shank and clamping chuck is important for perfect concentricity. In this article, we will introduce you to the different clamping surfaces HA, HB and HE and explain the consequences of choosing the wrong clamping surface.

1 milling cutter, 5 success stories: This is how the RF 100 Sharp impresses

The RF 100 Sharp solid carbide high-performance milling cutter is currently the sharpest milling cutter on the market and Gühring is therefore racking up success stories form satisfied customers around the world. We have now compiled five such success stories for you.

“Licence to mill”: Bond car milled from solid material

Bringing together the three best products makes the perfect process. Gühring and Blaser have combined an MQL oil with a solid carbide corner radii milling cutter and a tool holder. And showcase the advantages that collaborative engineering can yield.

6 reasons why your production needs a tool management system

Searching for tools takes an incredible amount of time. All tools have their place in our tool management cabinets. Tidy, locked, with controlled dispensing. In this article, you will find out how to revolutionise your production and save costs.

Four times more threads with hard milling

Tools for punching sheet metal have to withstand a lot. Hago Feinwerktechnik GmbH therefore uses materials of up to 66 HRC in its own toolmaking facilities. Here, two Gühring tools not only impress with low wear, but also with considerable cost savings.

Tool life up, costs down: three tools for higher parameters

Enjoy longer tool lives and save money at the same time: Hennecke from Sankt Augustin is managing to do that together with Gühring. Three SC highlight products show why the machine and system manufacturer relies almost exclusively on Gühring for milling.

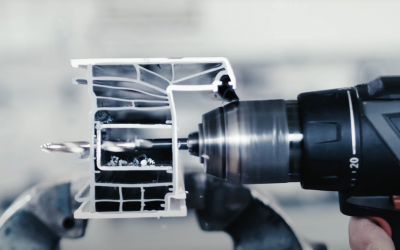

The new StepPower: circular holes by hand

Conventional handheld drills require a lot of force which can result in non-circular holes or annoying burrs at the hole exit. The new StepPower twist drill from Gühring masters these challenges. Its unique design ensures precise, circular holes.

One click to happiness: Provision of operating resources with GTMS

The service technicians from the machine manufacturer Fill from Gurten select their operating resources online and can have their toolbox sent out or prepared at their destination. This is made possible by the Gühring Tool Management Software (GTMS).